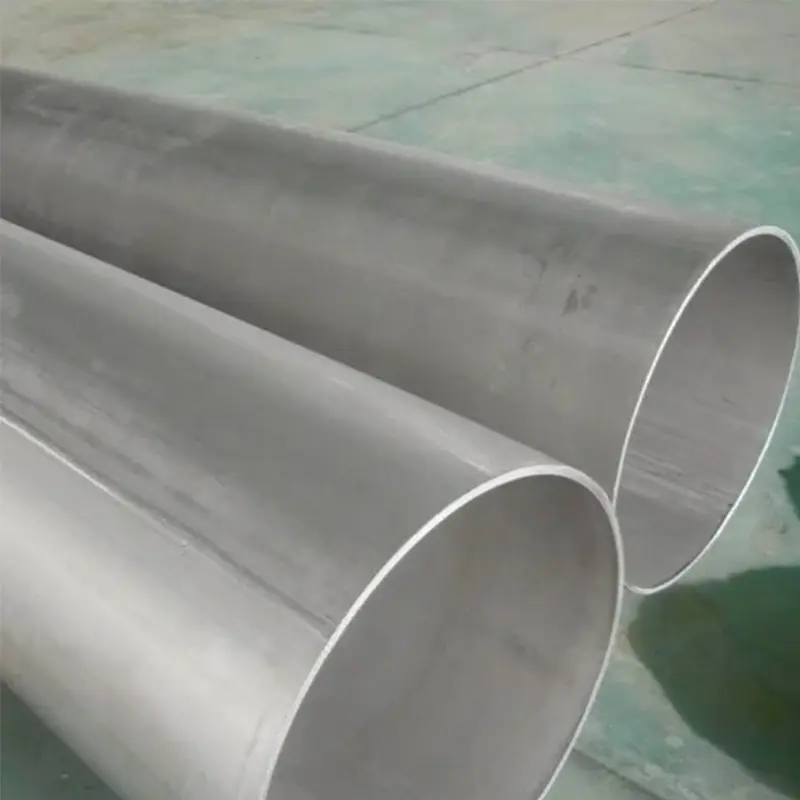

304/316 stainless steel welded pipe

specification

|

Product Name |

Stainless steel welded pipe |

|

Standard |

ASTM,JIS,DIN,GB,AISI,DIN,EN |

|

Material |

304、316、321、430、410、420、2205、17-4PH |

|

Outer diameter range |

Small diameter welded pipe: The outer diameter is usually between 6mm and 50mm, suitable for small equipment and piping systems. Medium diameter welded pipe: The outer diameter is usually between 50mm and 150mm, widely used in construction, chemical and food industries. Large diameter welded pipe: The outer diameter is usually 150mm to 600mm or larger, suitable for industries such as oil, gas and water treatment. |

|

Thickness range |

Small diameter welded pipe: The wall thickness is usually between 0.5mm and 3mm, suitable for light structures and small equipment. Medium diameter welded pipe: The wall thickness is usually between 3mm and 10mm, widely used in construction, chemical and food industries. Large diameter welded pipe: The wall thickness is usually 5mm to 20mm or thicker, suitable for industries such as oil, gas and water treatment. |

|

Length range |

The longest length is 12 meters, and can be customized by customers |

|

Error |

±1% |

|

Certification |

ISO 9001 ,CE,API |

|

Surface treatment |

Pickling, polishing, electrolytic polishing, sandblasting, coating, phosphating, passivation |

|

Country of origin |

China |

|

Main Applications |

1.Chemical Industry: Stainless steel welded pipes are often used in chemical reactors, storage tanks, piping systems, etc., and can withstand the transportation and storage of corrosive chemicals. |

|

2.Food and Beverage Industry: Due to its good hygiene properties and corrosion resistance, stainless steel welded pipes are widely used in piping systems in food processing, beverage production and pharmaceutical industries. |

|

|

3.Architecture and Structure: Stainless steel welded pipes are used in building structures, railings, handrails, etc., and are favored for their beauty and durability. |

|

|

4.Oil and Gas Industry: Pipelines used to transport oil, natural gas and other fluids, capable of withstanding high pressure and corrosive environments. |

|

|

5.Water treatment: Stainless steel welded pipes are used to transport and treat water in water treatment facilities because of their corrosion resistance and strength, which are suitable for various water qualities. |

|

|

6.Pharmaceutical Industry: Used in pharmaceutical equipment and pipelines to ensure the purity and safety of products. |

|

|

7.Automotive industry: Used in exhaust systems, fuel pipes, etc. due to its high temperature and corrosion resistance. |

|

|

8.Aerospace: Used in aerospace equipment due to its light weight and high strength properties. |

|

|

Package |

Simple packaging, reinforced packaging, wooden frame, metal frame, pallet, wrapping |

|

Payment Term |

TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

|

After-sales service |

1. Quality assurance period 2. Return and exchange policy 3. Delivery and acceptance assistance 4. Customer feedback collection |

Product Display

Classification of stainless steel welded pipes

Classification by material:

Austenitic stainless steel welded pipe: such as 304, 316, etc., with good corrosion resistance and formability.

Ferritic stainless steel welded pipe: such as 430, with low corrosion resistance, mainly used in kitchen equipment, etc.

Martensitic stainless steel welded pipe: such as 410, 420, with higher strength and hardness, suitable for knives and cutting tools.

Duplex stainless steel welded pipe: Such as 2205, it combines the characteristics of austenite and ferrite, with excellent strength and corrosion resistance.

Precipitation hardening stainless steel welded pipe: such as 17-4 PH, with high strength and good corrosion resistance.

Classification by production process:

Welded Stainless Steel Pipe: manufactured by welding process, suitable for various applications.

Seamless stainless steel pipe: manufactured by extrusion or rolling process, suitable for high pressure and high temperature environment.

Classification by purpose:

Industrial stainless steel welded pipe: used in chemical, petroleum, natural gas and other industries.

Food grade stainless steel welded pipe: used in food and beverage industry, in line with hygiene standards.

Stainless steel welded pipe for construction: used for building structure, decoration, etc.

Classification by outer diameter and wall thickness:

Small diameter welded pipe: The outer diameter is usually between 6mm and 50mm.

Medium diameter welded pipe: The outer diameter is usually between 50mm and 150mm.

Large diameter welded pipe: The outer diameter is usually above 150mm.

Advantages

Corrosion resistance: Stainless steel welded pipes have excellent corrosion resistance and can resist the erosion of various chemical media, making them suitable for use in harsh environments.

High strength: Stainless steel welded pipes have high strength and can withstand greater pressure and load, and are suitable for high pressure and high temperature applications.

High temperature resistance: Some types of stainless steel welded pipes (such as 316 and 321) have good high temperature resistance and are suitable for use in high temperature environments.

Hygiene: The surface of stainless steel welded pipe is smooth and not easy to breed bacteria. It meets the hygiene standards of the food and pharmaceutical industries and is suitable for the transportation of food and beverages.

Aesthetics: Stainless steel welded pipes have good appearance and are smooth and bright after surface treatment, making them suitable for construction and decoration.

Easy to clean: The surface of the stainless steel welded pipe is not easy to adhere to dirt, easy to clean and maintain, and suitable for environments that require frequent cleaning.

Recyclability: Stainless steel is a recyclable material, which meets the requirements of sustainable development and reduces the impact on the environment.

Diversity: Stainless steel welded pipes have a variety of specifications, materials and surface treatments, which can be selected according to different application requirements.

Production process

Raw material preparation:

Select the appropriate stainless steel plate or strip, usually based on the required welded pipe specifications and material.

Cutting:

Cut stainless steel sheets or strips into required width and length for subsequent forming and welding.

Molding:

Roll the cut stainless steel strip into a tube through cold rolling or hot rolling process. Common forming methods are:

Tube rolling: Roll the strip into a round tube.

Forming machine: The strip is gradually formed into a tube using a forming machine.

Welding:

Weld the formed pipes. Common welding methods include:

TIG welding (argon arc welding): suitable for high-quality welding with smooth welds.

MIG welding (gas shielded welding): suitable for large-scale production and fast welding speed.

High frequency welding: suitable for the production of thin-walled tubes, with high welding efficiency.

Cooling:

After welding, the welded pipe needs to be cooled to ensure the strength and stability of the weld.

Pickling and passivation:

The welded pipe is pickled to remove surface oxides and welding residues, and then passivated to improve corrosion resistance.

Inspection:

Carry out quality inspection on welded pipes, including appearance inspection, dimension measurement, weld inspection (such as ultrasonic inspection, X-ray inspection, etc.) to ensure that the products meet the standards.

Surface treatment:

Surface treatment such as polishing, sandblasting, coating, etc. can be performed according to customer needs to improve aesthetics and corrosion resistance.

Packaging and Shipping:

Pack qualified stainless steel welded pipes and prepare to ship them to customers.