309(309S) high quality stainless steel plate

specification

|

Product Name |

309(309S) stainless steel plate |

|

Standard |

ASTM,JIS,DIN,GB,AISI,DIN,EN |

|

Thickness |

0.3mm-200mm |

|

Width |

40mm-600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc. |

|

Length |

2000mm, 2438mm, 3000mm, 5800mm, 6000mm, 12000mm, etc. |

|

Error |

±1% |

|

Certification |

ISO 9001 ,CE,API |

|

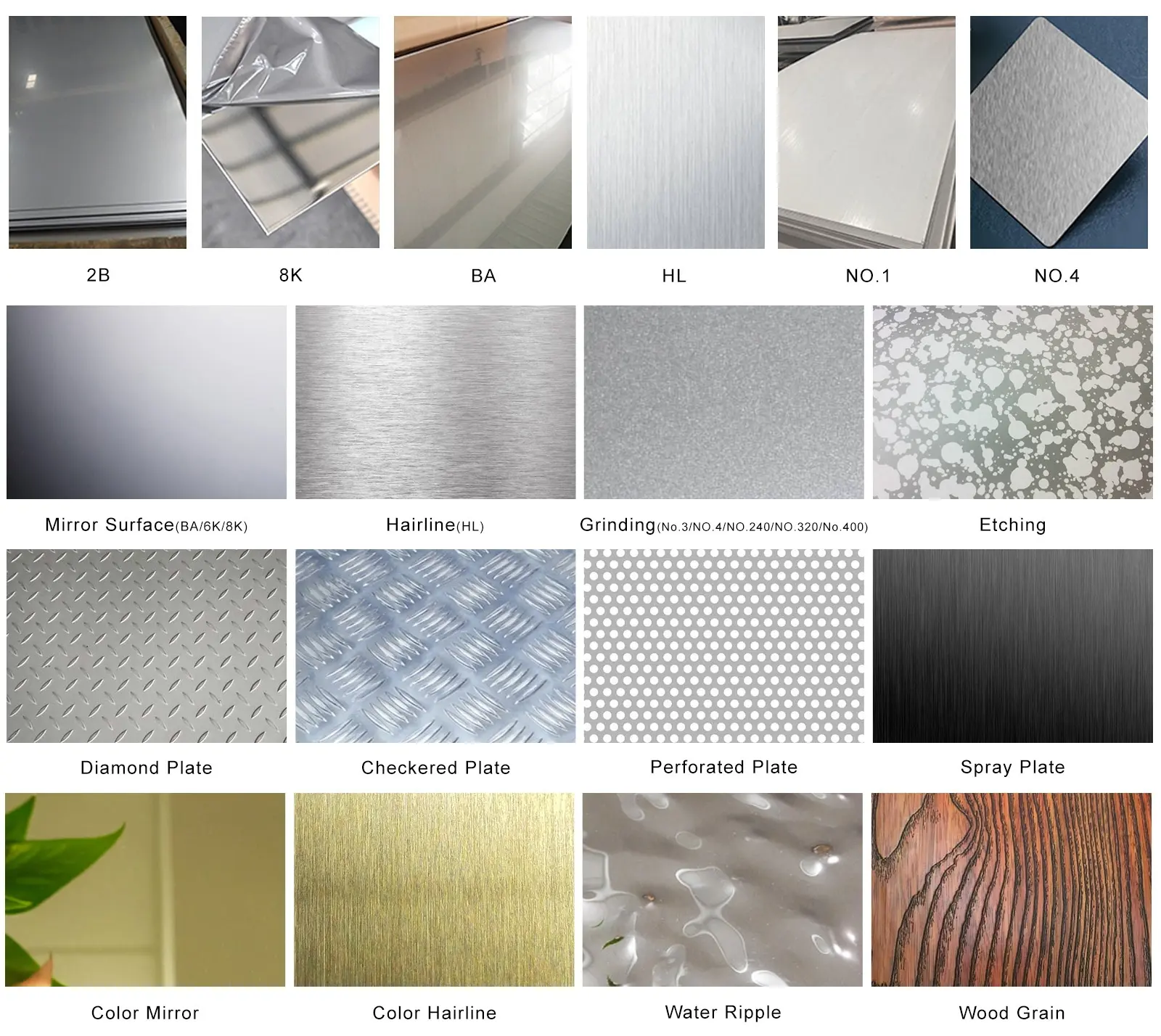

Surface treatment |

BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

|

Country of origin |

China |

|

Main Applications |

1.High temperature equipment: Due to their excellent high temperature resistance, 309 and 309S stainless steel plates are often used to manufacture high temperature furnaces, incinerators, heat exchangers and other equipment. |

|

2.Chemical Industry: In chemical production, these stainless steel materials can resist corrosion from a variety of chemical media and are suitable for reactors, storage tanks and pipelines, etc. |

|

|

3.Oil and Gas Industry: Used in oil refining and natural gas processing equipment, able to withstand high temperatures and corrosive environments. |

|

|

4.Electric Power Industry: 309 and 309S stainless steel plates are widely used in boilers, flues and other high-temperature components of power plants. |

|

|

5.Food Processing: In some food processing equipment, 309S is used because of its good corrosion resistance and hygienic properties. |

|

|

6.Architecture and decoration: In some special architectural and decorative applications, 309 and 309S stainless steel plates can also be used as exterior decorative materials. |

|

|

Package |

Bundling packaging、Wooden box packaging、Plastic film packaging、Pallet packaging、Anti-rust oil coating、Bubble film packaging |

|

Payment Term |

TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

|

After-sales service |

1. Quality assurance period 2. Return and exchange policy 3. Delivery and acceptance assistance 4. Customer feedback collection |

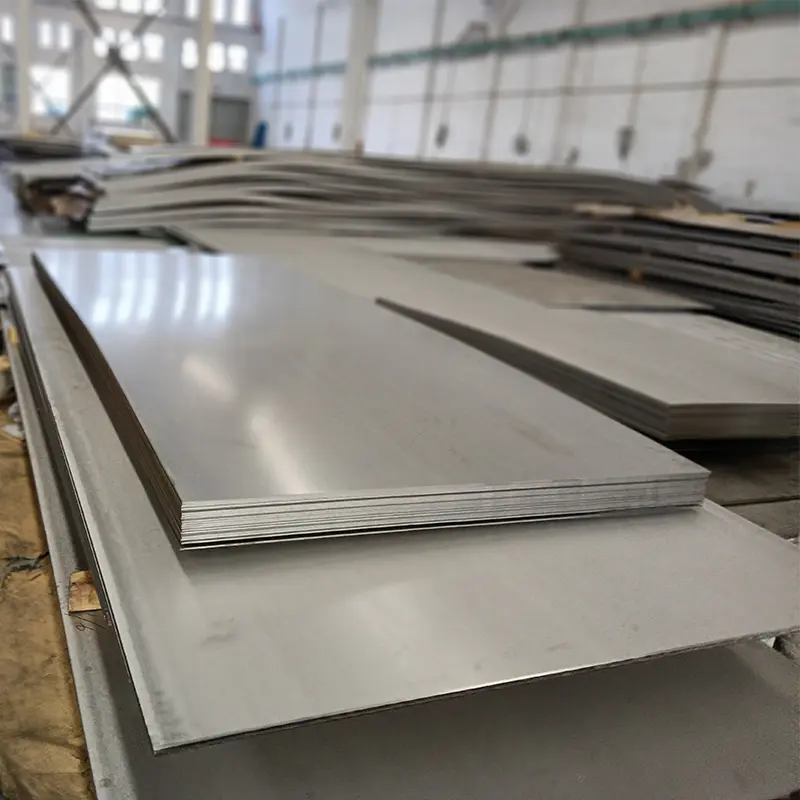

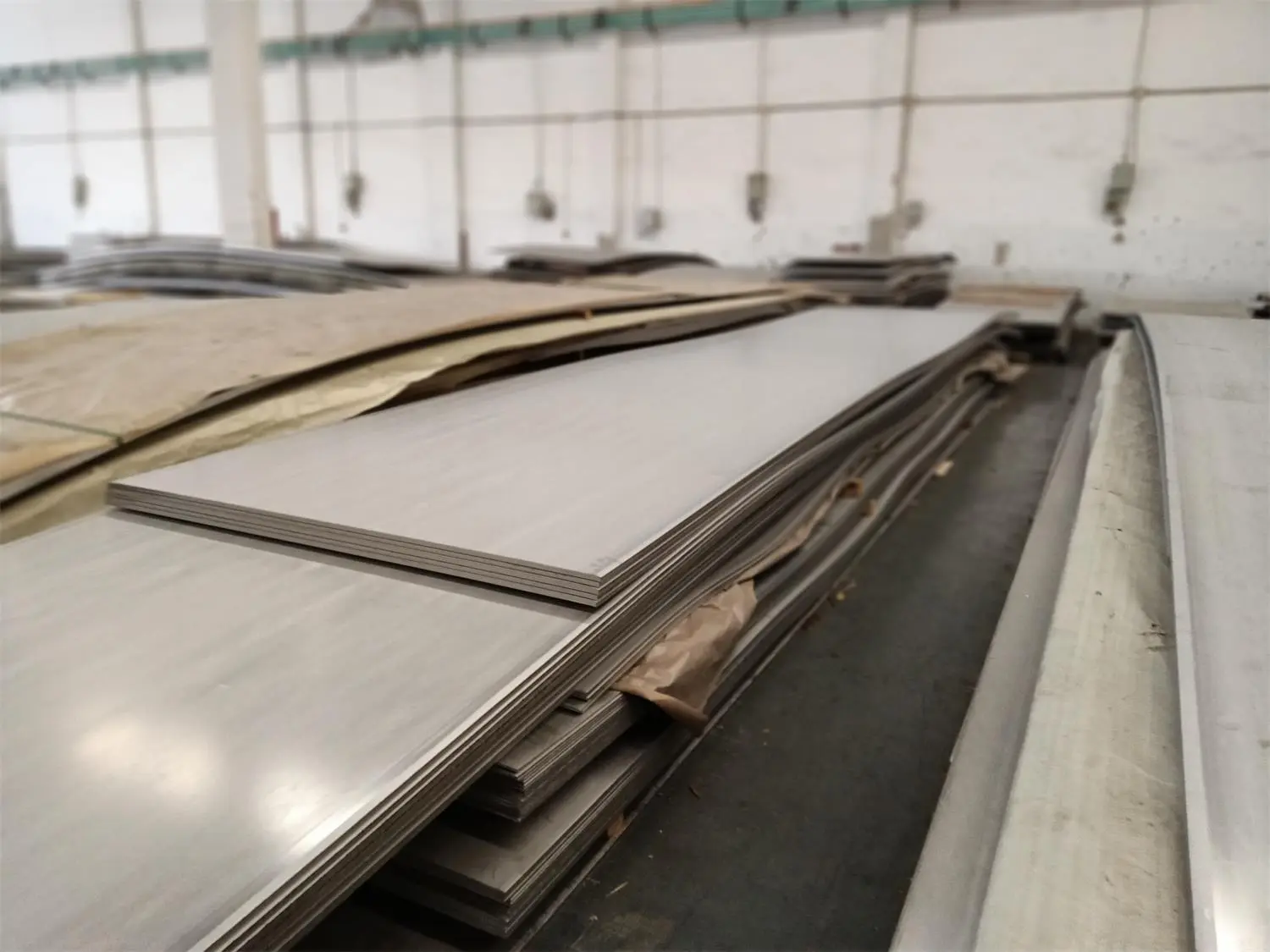

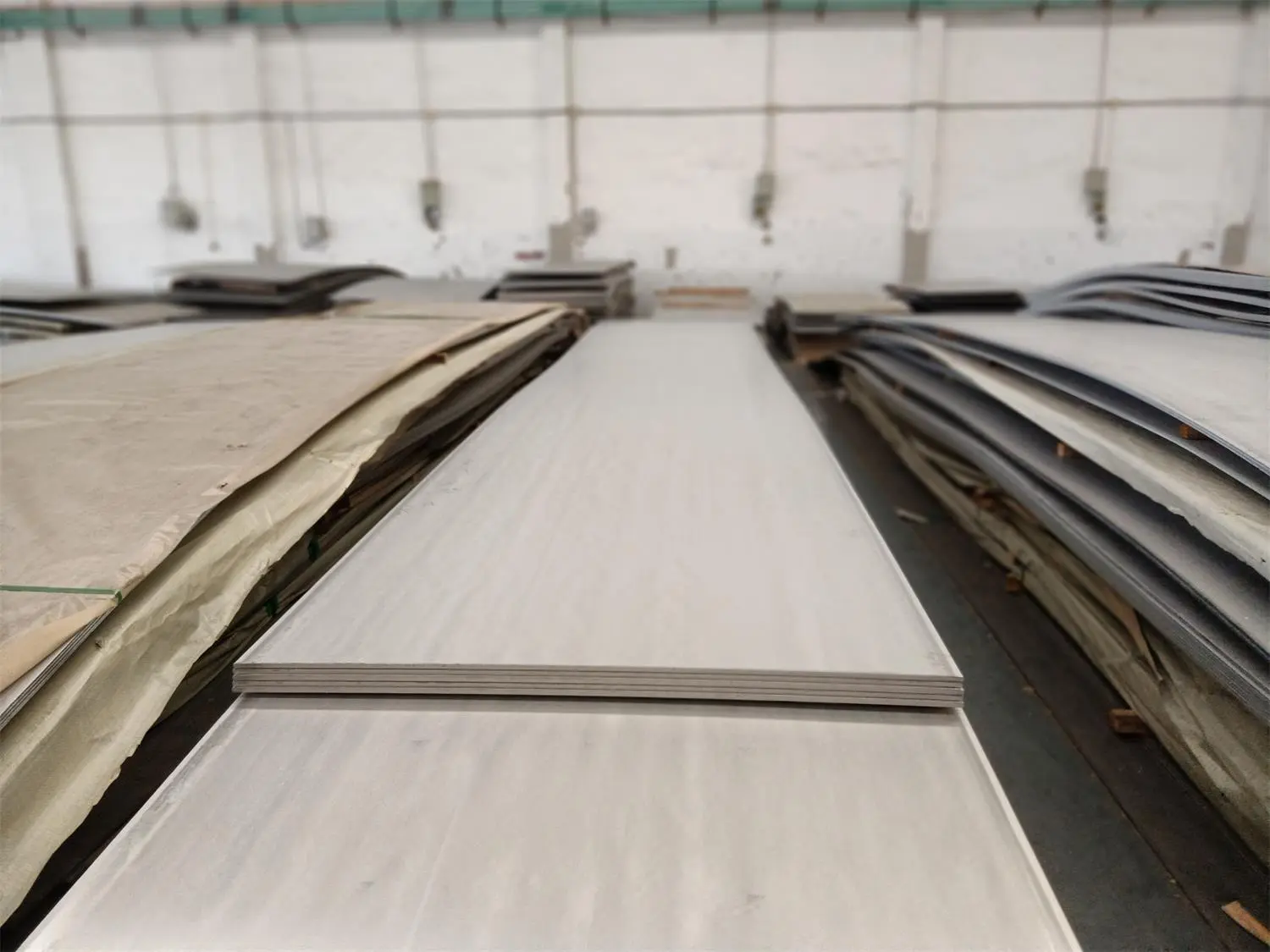

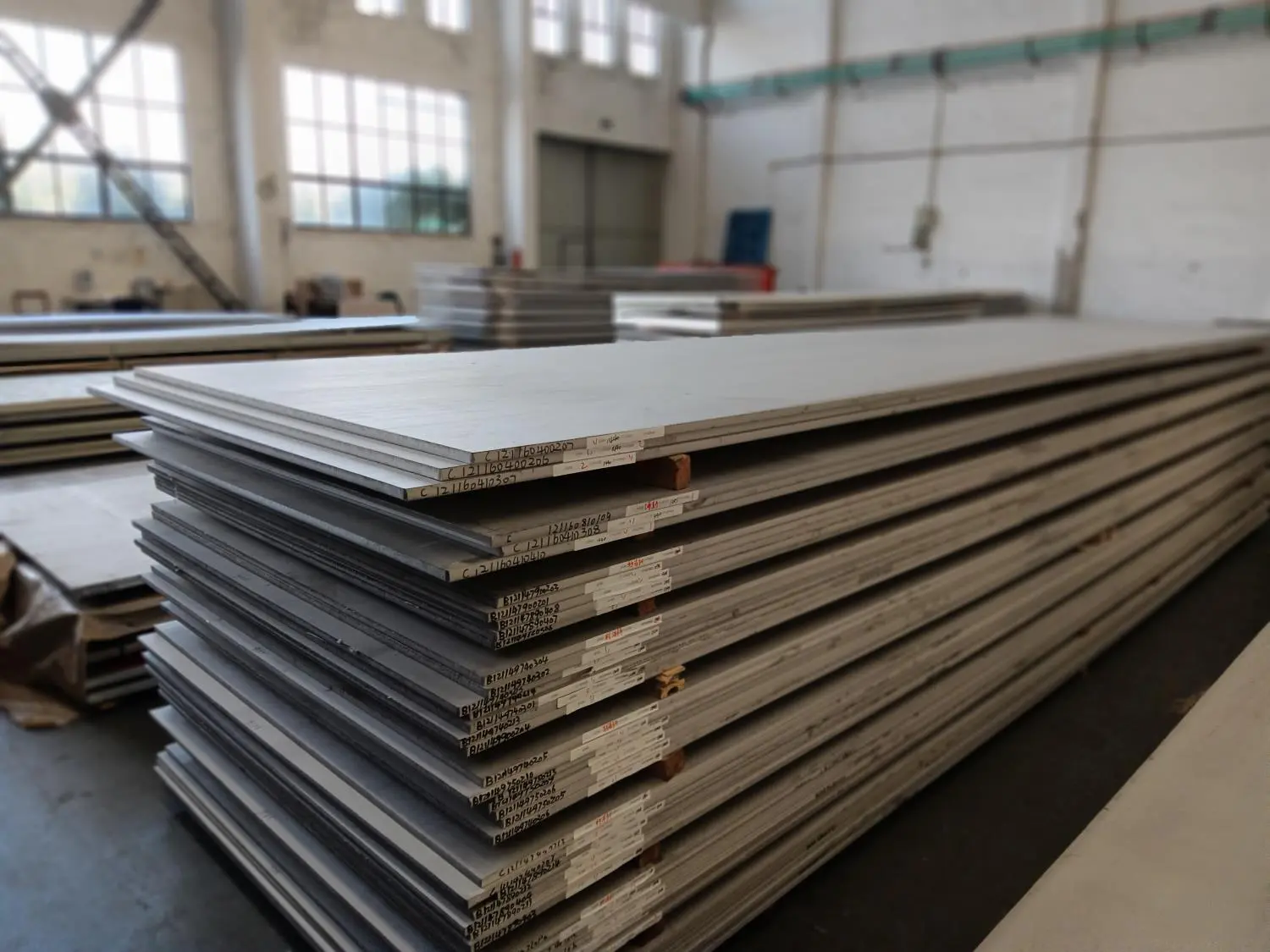

Product Display

Chemical Composition

|

C |

Si |

Mn |

Cr |

Ni |

S |

P |

|

≤ 0.08 |

≤0.75 |

≤ 2.0 |

22.0~24.0 |

12.0~15.0 |

≤ 0.03 |

≤ 0.045 |

Mechanical Properties

|

Tensile Strength Kb (MPa) |

Yield Strength σ0.2 (MPa) |

Elongation D5 (%) |

Hardness |

|

≥515 |

≥205 |

≥35 |

≤ 217HB |

Physical Performance

|

Density(g/cm³) |

Modulus of Elasticity(Gpa) |

Coefficient of Thermal Expansion(10-6/°C) |

Coefficient of Thermal Conductivity(W/m*K) |

Resistivity(ΜΩ. cm) |

|

7.98 |

200 |

14.9 |

15.6 |

78 |

Surface Selection