01

310S Stainless bar: Stable in furnaces

specification

| Product Name | 310S stainless steel bar |

| Type | Round Bar |

| Surface | Black,bright,rough turned,grinding,centreless Ground etc |

| Standard | GB,AISI,ASTM,DIN,EN,SUS,UNS etc |

| Diameter | 3-800mm or as your requirement |

| Sample | provided freely |

| Stock or not | enough stocks, delivery time is soon |

| Technigue | Hot Rolled,Cold Rolled,Cold Drawn,Forged |

| Testing Methods | Flaw detection, Eddy current testing, Hydrostatic testing or Ultrasonic examination and also with chemical and physical property inspection |

| Grade | 200 series: 201,202,202Cu 300 series: 301,303,303Cu,304,304L,304H,309S,310S,316/L/H/Ti,321/H,347/H,330, 400 series: 409/L,410,416/F,420/F,430,431,440C,441,444,446, 600 series: 13-8ph,15-5ph,17-4ph,17-7ph(630,631),660A/B/C/D, Duplex: 2205(UNS S31803/S32205),2507(UNS S32750),UNS S32760,2304,LDX2101.LDX2404,LDX4404,904L Others: 153Ma,254SMo,253Ma,654SMo,F15,Invar36,1J22,N4,N6 etc |

| Third Party Inspection | SGS BV MTC |

| Trade Terms | FOB CIF CFR |

| Payment Terms:FOB 30%T/T,70% before shipment CIF 30% pre-payment and the balance to be paid upon B/L (copy) or Irrevocable 100% L/C at sight | |

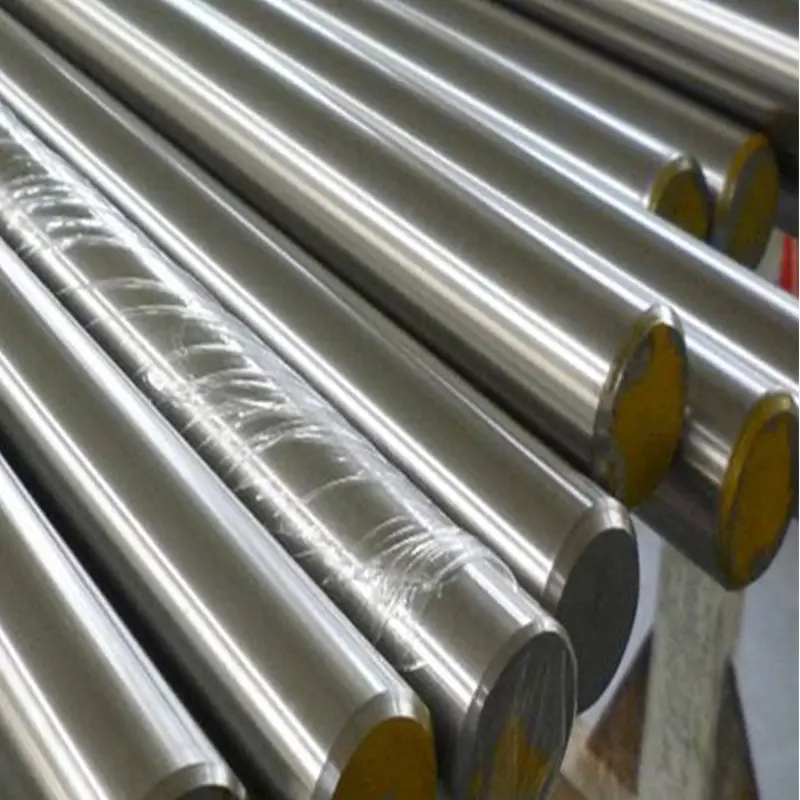

Product Display

Chemical Composition

|

C |

Si |

Mn |

Cr |

Ni |

S |

P |

|

≤ 0.08 |

≤1.0 |

≤ 2.0 |

24.0~26.0 |

19.0~22.0 |

≤ 0.03 |

≤ 0.045 |

Mechanical Properties

|

Tensile Strength Kb (MPa) |

Yield Strength σ0.2 (MPa) |

Elongation D5 (%) |

Hardness |

|

≥520 |

≥205 |

≥40 |

≤ 217HB;≤ 95HRB |

Physical Performance

|

Density(g/cm³) |

Modulus of Elasticity(Gpa) |

Coefficient of Thermal Expansion(10-6/°C) |

Coefficient of Thermal Conductivity(W/m*K) |

Resistivity(ΜΩ. cm) |

|

9.01 |

200 |

14.4 |

13.8 |

94 |