430 high quality stainless steel plat

specification

|

Product Name |

430 stainless steel plate |

|

Standard |

ASTM,JIS,DIN,GB,AISI,DIN,EN |

|

Thickness |

0.3mm-200mm |

|

Width |

40mm-600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc. |

|

Length |

2000mm, 2438mm, 3000mm, 5800mm, 6000mm, 12000mm, etc. |

|

Error |

±1% |

|

Certification |

ISO 9001 ,CE,API |

|

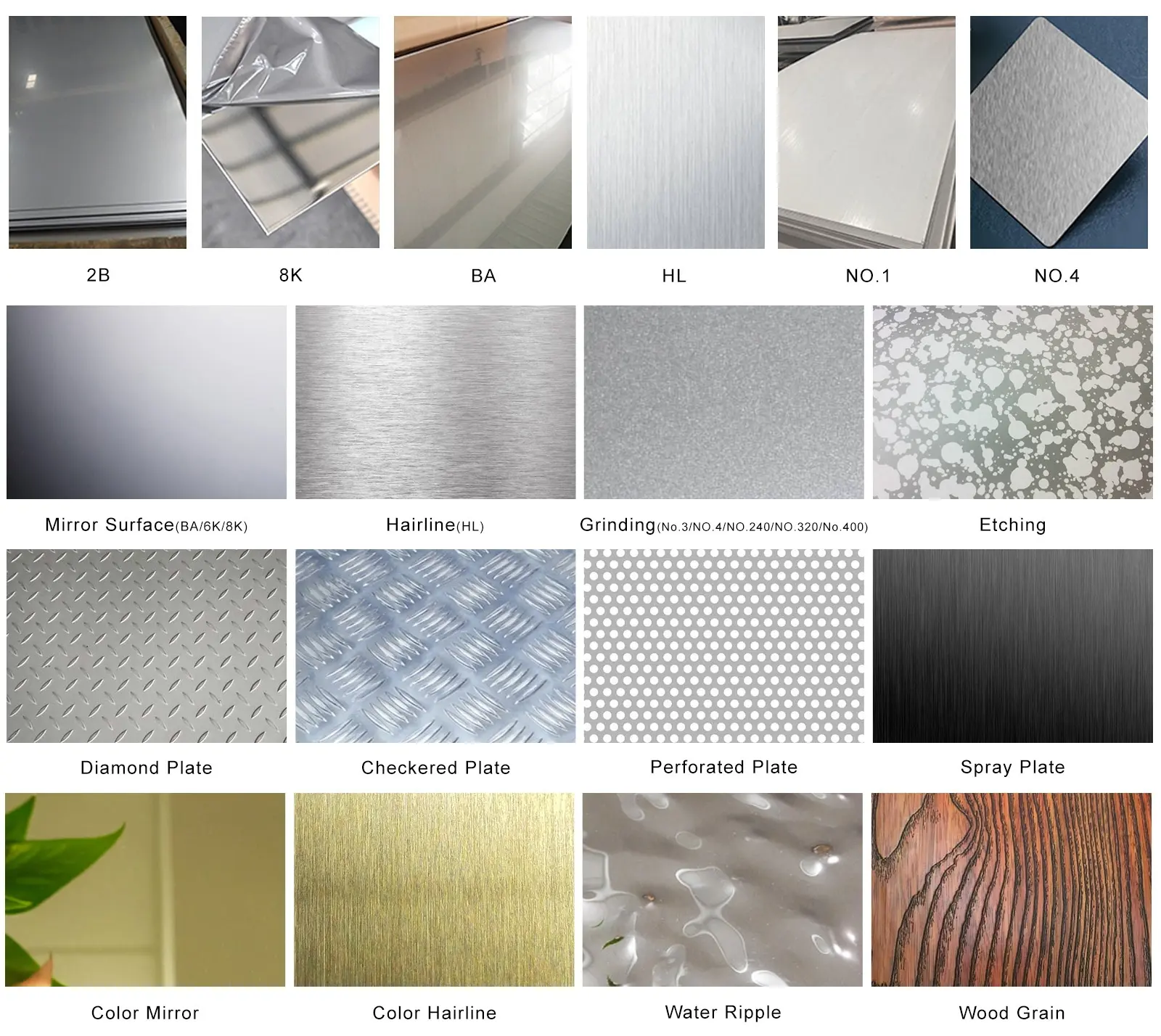

Surface treatment |

BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

|

Country of origin |

China |

|

Main Applications |

1.Kitchen equipment: Due to its good corrosion resistance, 430 stainless steel is often used to make kitchen utensils, tableware, kitchen utensils, dishwasher liners, etc. |

|

2.Home appliances: In some home appliances, such as refrigerators, washing machines, microwave ovens, etc., 430 stainless steel is used as the shell material. |

|

|

3.Automotive Industry: 430 stainless steel is used in automotive exhaust systems, trims and other parts due to its high temperature and corrosion resistance. |

|

|

4.Architectural decoration: In the construction industry, 430 stainless steel is often used for indoor and outdoor decoration, handrails, door and window frames, etc. |

|

|

5.Food Processing: Due to its hygienic properties, 430 stainless steel is also widely used in food processing equipment and storage containers. |

|

|

6.Chemical Equipment: In certain chemical environments, 430 stainless steel can be used to manufacture pipes, valves and other equipment. |

|

|

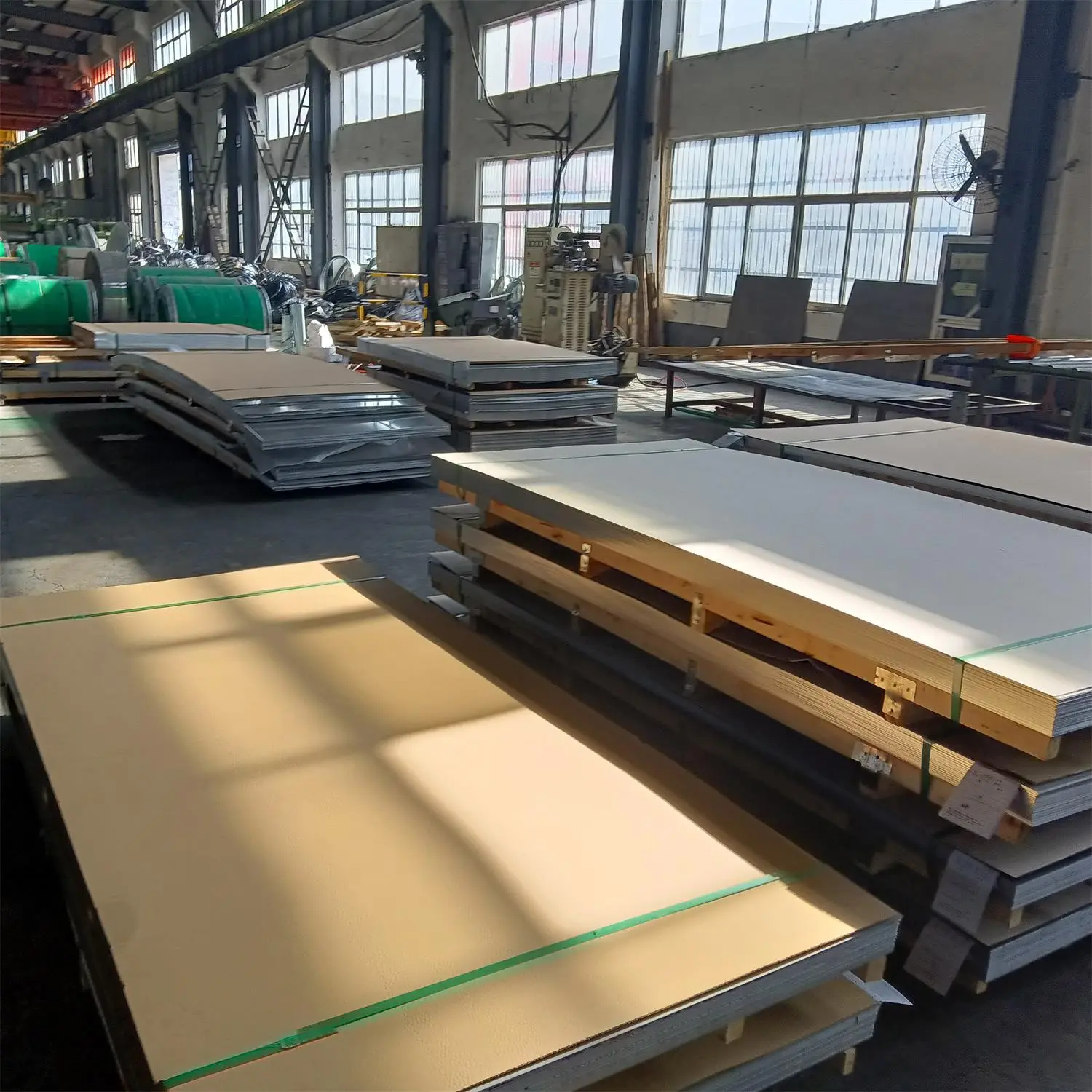

Package |

Bundling packaging、Wooden box packaging、Plastic film packaging、Pallet packaging、Anti-rust oil coating、Bubble film packaging |

|

Payment Term |

TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

|

After-sales service |

1. Quality assurance period 2. Return and exchange policy 3. Delivery and acceptance assistance 4. Customer feedback collection |

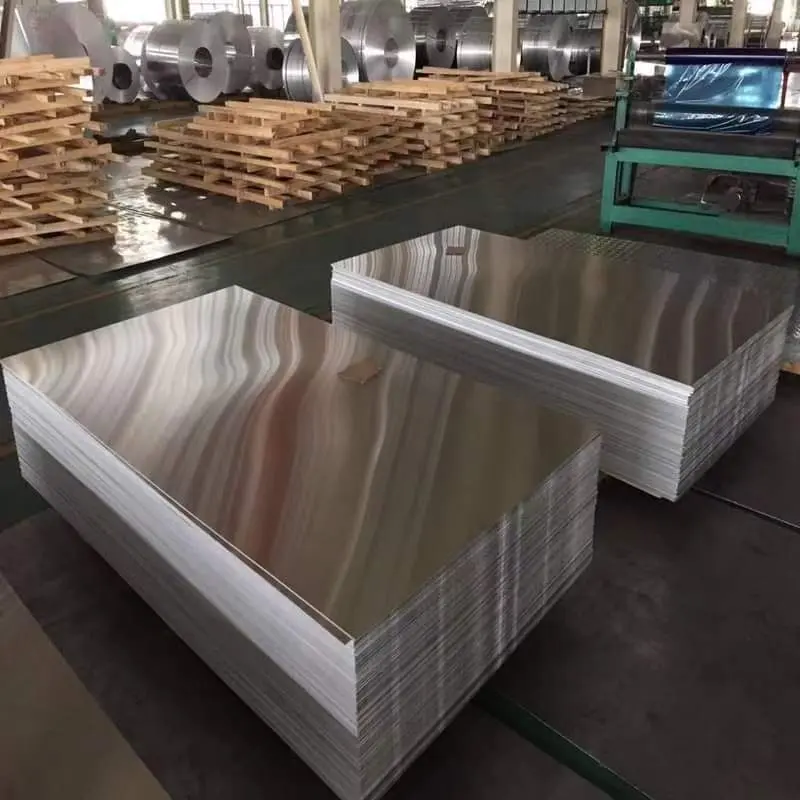

Product Display

Chemical Composition

|

C |

Si |

Mn |

Cr |

Ni |

S |

P |

|

≤ 0.12 |

≤ 1.0 |

≤ 1.0 |

16.0~18.0 |

≤ 0.75 |

≤ 0.03 |

≤ 0.04 |

Mechanical Properties

|

Tensile Strength Kb (MPa) |

Yield Strength σ0.2 (MPa) |

Elongation D5 (%) |

Hardness |

|

≥634 |

≥440 |

≥20 |

Annealing≤ 223HB; quenching and tempering ≥ 192HB |

Physical Performance

|

Density(g/cm³) |

Modulus of Elasticity(Gpa) |

Coefficient of Thermal Expansion(10-6/°C) |

Coefficient of Thermal Conductivity(W/m*K) |

Resistivity(ΜΩ. cm) |

|

7.70 |

200 |

10.4 |

23.9 |

360 |

Surface Selection