01

7075 Aluminum Coil for Aerospace Projects

specification

| Product Name | 7075 Aluminum Coil |

| Surface | Mill finish, no stains, without rough selvedge,Anodizing |

| Grade | 1100/1050/1060/1070/1080/1200/1350 |

| 3003/3004/3104/3005/3105 | |

| 2014/2017A/2024/2A12/2A14/2A50/2219 | |

| 5A05/5A06/5042/5052/5083/5086/5182/5251/5454/5754 | |

| 6061/6082/6063/6K61/6Z61 | |

| 7A04/7049/7050/7072/7075 | |

| 4032/8011 | |

| Temper | HO,H12,H14,H16,H18,H19,H22,H24,H26,H28,F,H112,T651,T3,T451,T4,T6,ect. |

| Width | 3mm-1500mm |

| Package | Export wooden pallets, craft paper. |

| Application | Building,Boat,Truck,Tanker,Machine |

| Quality of material | Totally free film defects like white rust, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set. |

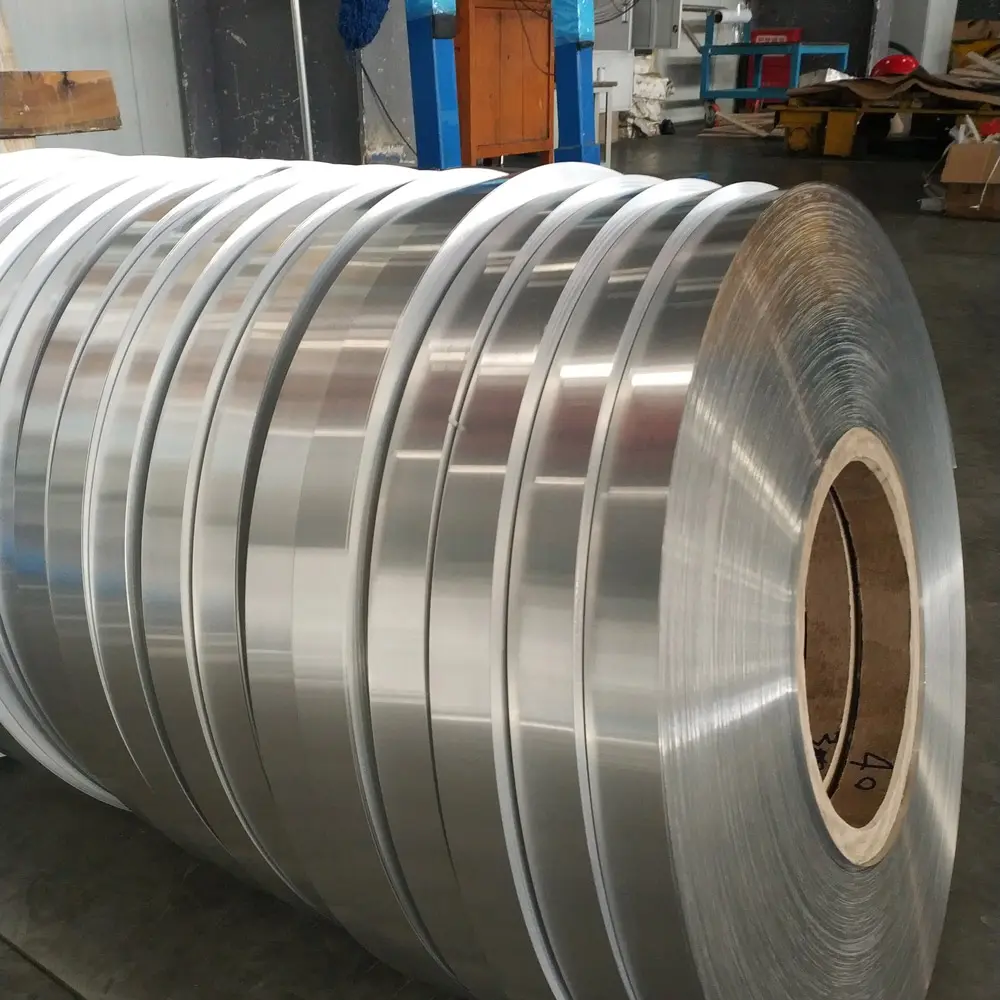

Product Display

Chemical Composition

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Others: Each |

Others: Total |

Al: Min. |

|

7075 |

0.40 |

0.50 |

1.2~2.0 |

0.30 |

2.1~2.9 |

0.18~0.28 |

5.1~6.1 |

0.20 |

0.05 |

0.15 |

Allowance |

Mechanical Properties

| Tensile Strength (MPa) | Yield Strength (MPa) | Elongation Rate (%) | Hardness (HV) |

| 572 | 503 | 11 | 175 |

Physical Performance

| Density | Melting Point | Modulus of Elasticity | Thermal Conductivity |

| 2.81 Kg/m³ | 477-635 °C | 71.7 GPa | 130 W/m.K |

Annealing State

|

Brand |

Annealing State |

|

1xxx: 1050, 1050A, 1060, 1100 |

O, H12, H14, H16, H18, H22, H24, H26, H28, H111 |

|

3xxx: 3003, 3004, 3005, 3105 |

|

|

5xxx: 5005, 5052, 5754, 5083, 5086, 5182, 5049, 5251, 5454 |

O, H22, H24, H26, H28, H32, H34, H36, H38, H111 |

|

6xxx: 6061, 6082 |

T4, T6, T451, T651 |

|

2xxx: 2024 |

T3, T351, T4 |

|

7xxx: 7075 |

T6, T651 |

Scope of Application

|

Aluminum Uses And Application Area |

|

|

Food Packaging |

Beverage can ends, cans, bottle caps, etc. |

|

Building |

Curtain walls, cladding, suspended ceilings, thermal insulation, venetian blinds, etc. |

|

Transportation |

Auto parts, passenger car bodies, aviation ships and air cargo containers. |

|

Electronic Equipment |

Electrical appliances, communication equipment,PCPlate drilling guide, lighting and heat dissipation materials, etc. |

|

Consumer Goods |

Umbrellas, cooking utensils, sports equipment, etc |

|

Other |

Military, color coated aluminum plate |