904L high quality stainless steel plate

specification

|

Product Name |

904L stainless steel plate |

|

Standard |

ASTM,JIS,DIN,GB,AISI,DIN,EN |

|

Thickness |

0.3mm-200mm |

|

Width |

40mm-600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc. |

|

Length |

2000mm, 2438mm, 3000mm, 5800mm, 6000mm, 12000mm, etc. |

|

Error |

±1% |

|

Certification |

ISO 9001 ,CE,API |

|

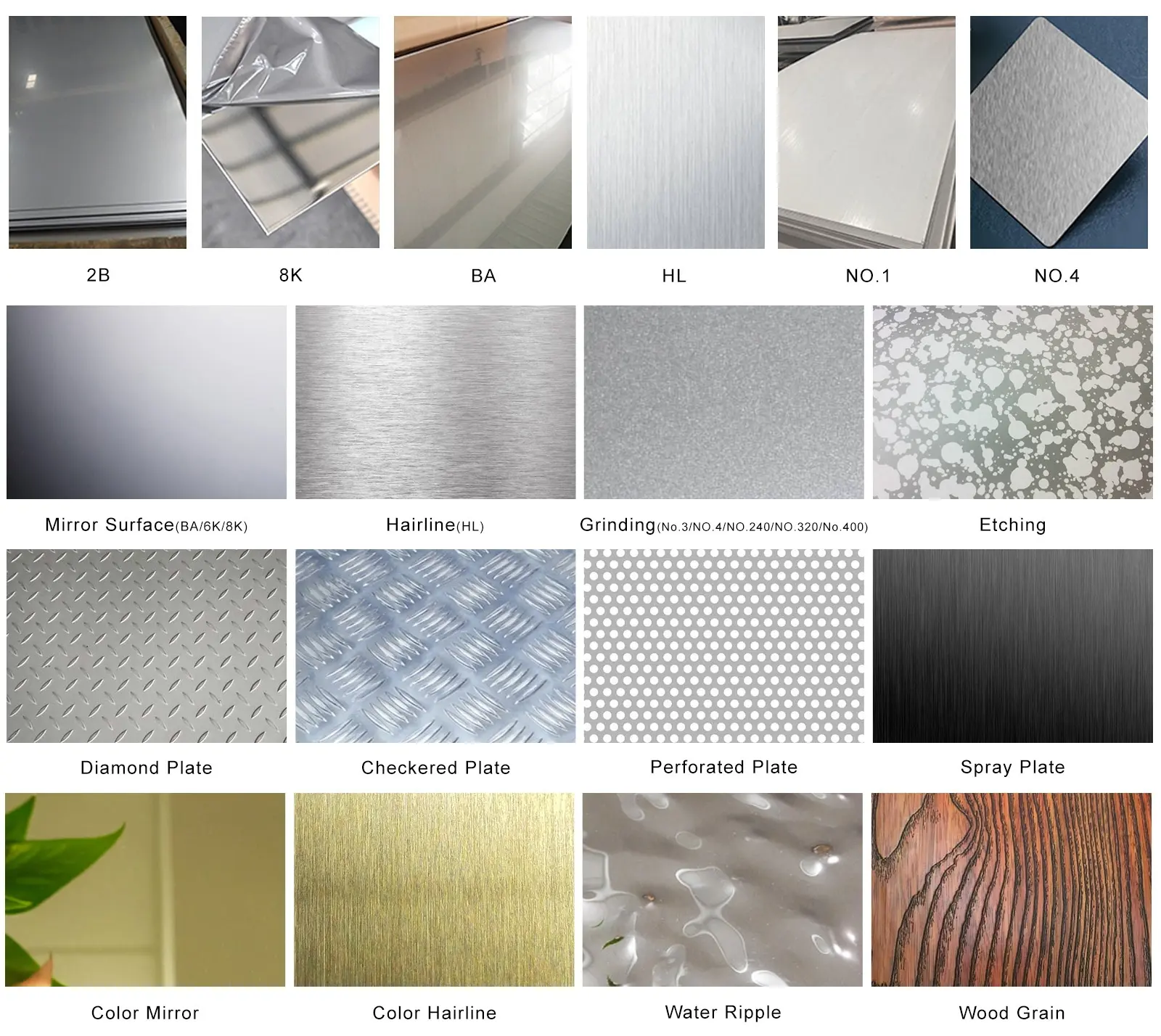

Surface treatment |

BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

|

Country of origin |

China |

|

Main Applications |

1.Chemical Industry: Due to its excellent corrosion resistance, 904L stainless steel is often used to manufacture chemical equipment, such as reactors, heat exchangers, storage tanks and pipelines, especially in the processing of strong acids (such as sulfuric acid, phosphoric acid) and chloride environments. |

|

2.Oil and Gas Industry: In the extraction, transportation and refining of oil and gas, 904L stainless steel is widely used in pipes, valves and other equipment to resist corrosion and high temperature environments. |

|

|

3.Marine Engineering: Due to its good resistance to seawater corrosion, 904L stainless steel is suitable for the construction of offshore platforms, ships and other marine facilities. |

|

|

4.Pharmaceutical industry: In pharmaceutical equipment and containers, 904L stainless steel is widely used due to its excellent hygiene and corrosion resistance. |

|

|

5.Food processing: In food processing and storage equipment, 904L stainless steel is also used to ensure food safety and prevent corrosion. |

|

|

6.Power Industry: In some power equipment, 904L stainless steel is used to make corrosion-resistant components, especially in chemical processing and cooling systems. |

|

|

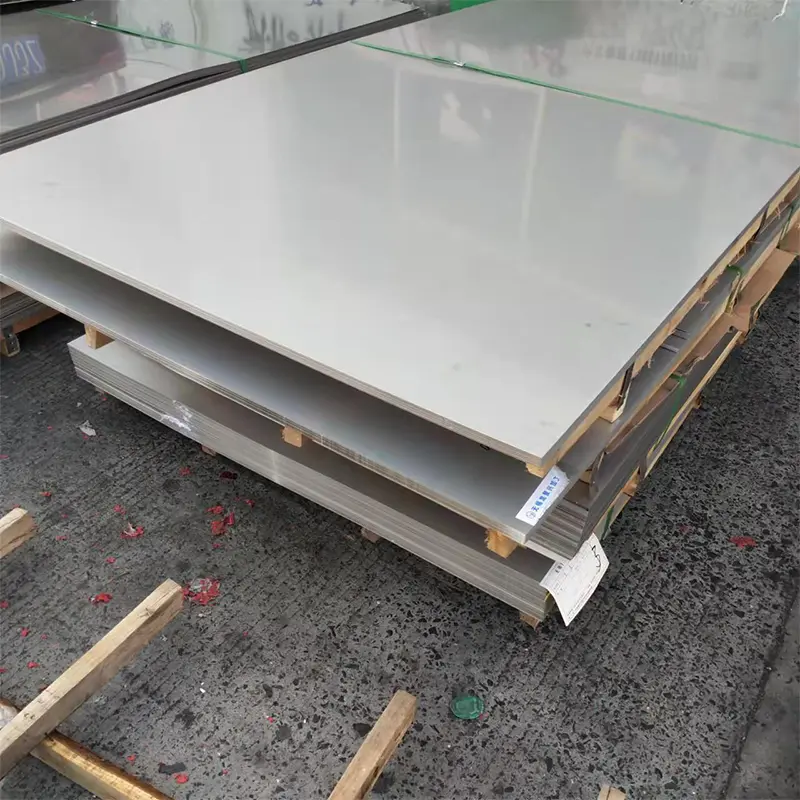

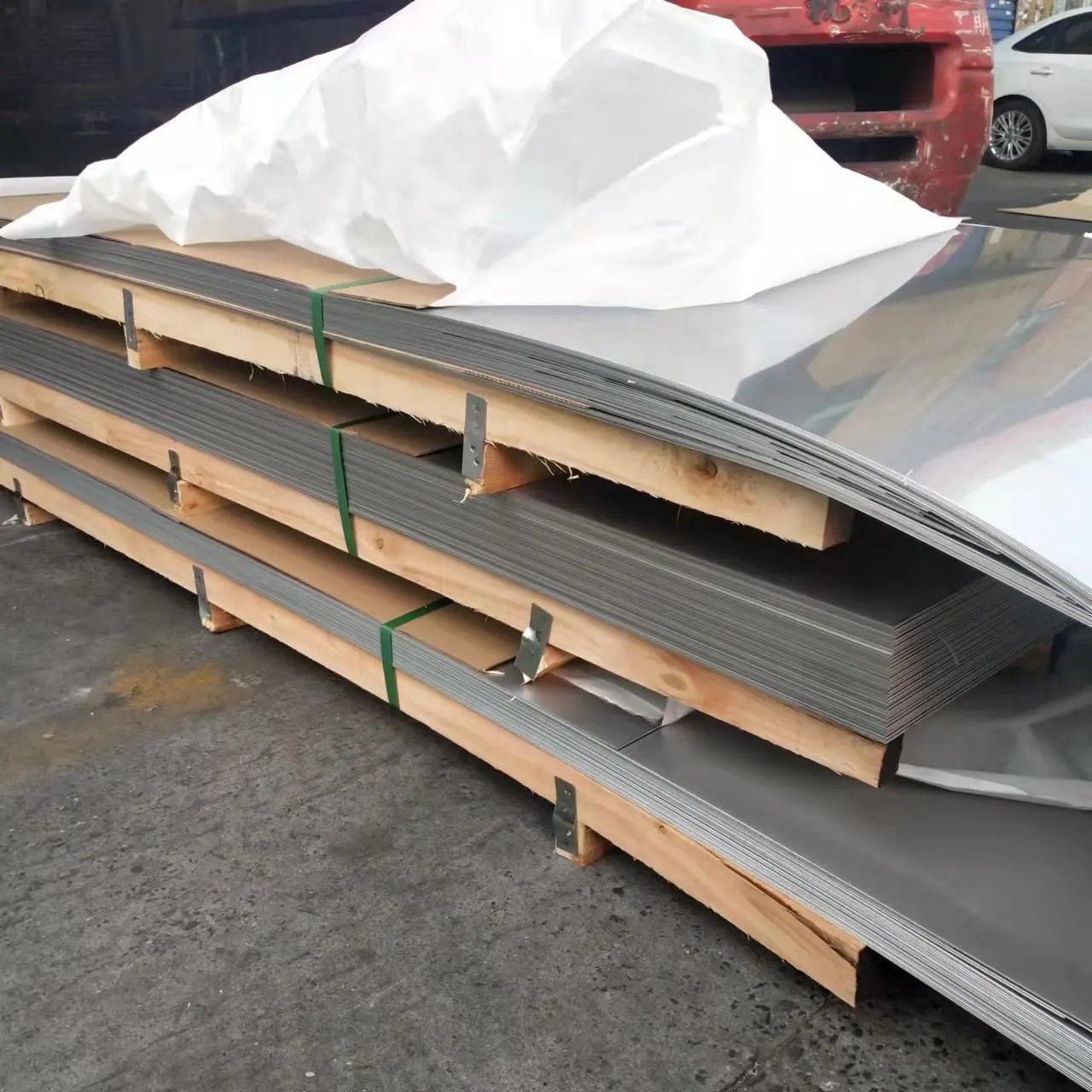

Package |

Bundling packaging、Wooden box packaging、Plastic film packaging、Pallet packaging、Anti-rust oil coating、Bubble film packaging |

|

Payment Term |

TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

|

After-sales service |

1. Quality assurance period 2. Return and exchange policy 3. Delivery and acceptance assistance 4. Customer feedback collection |

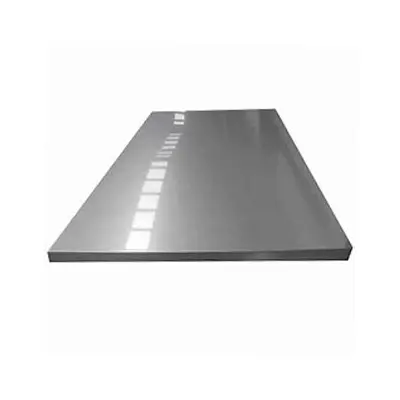

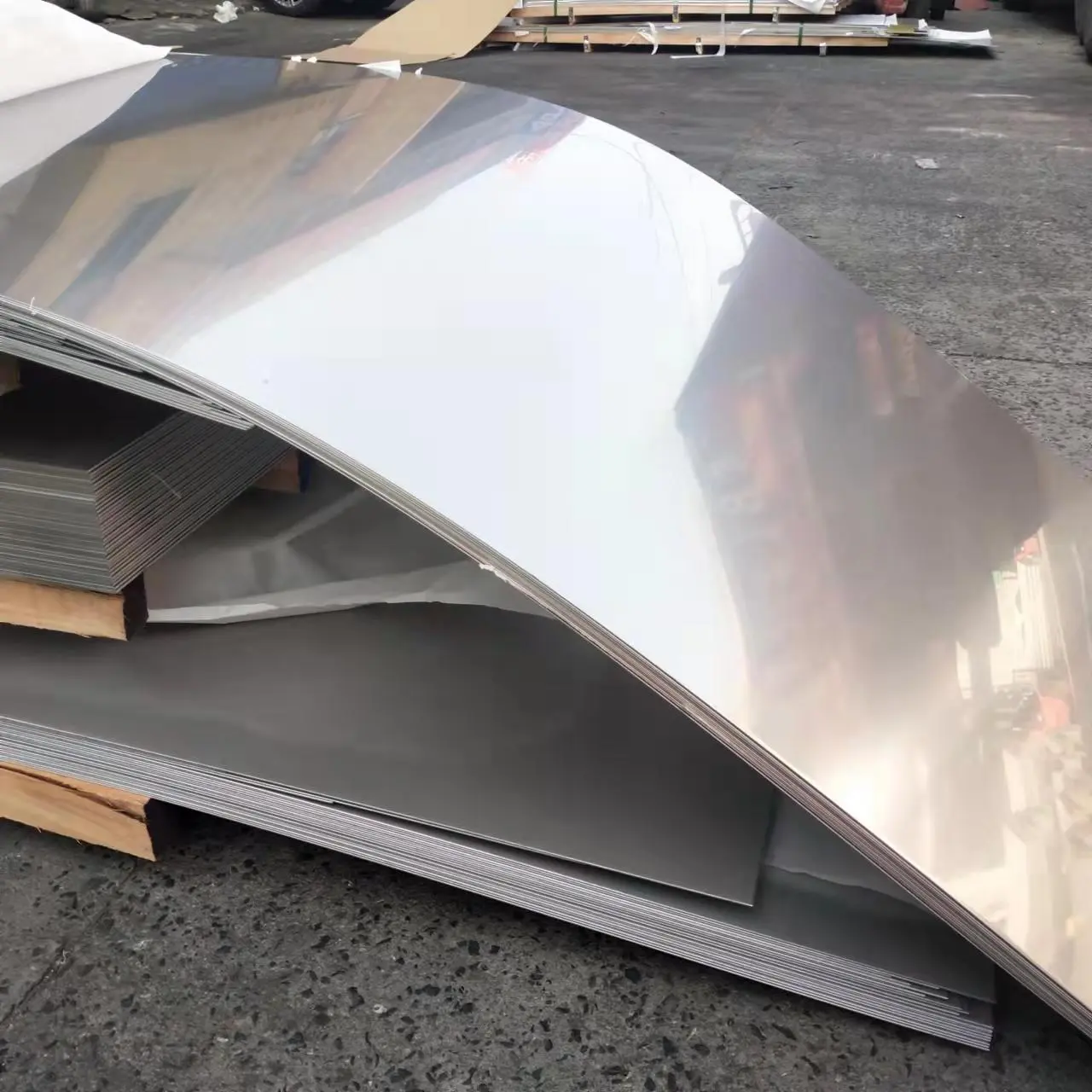

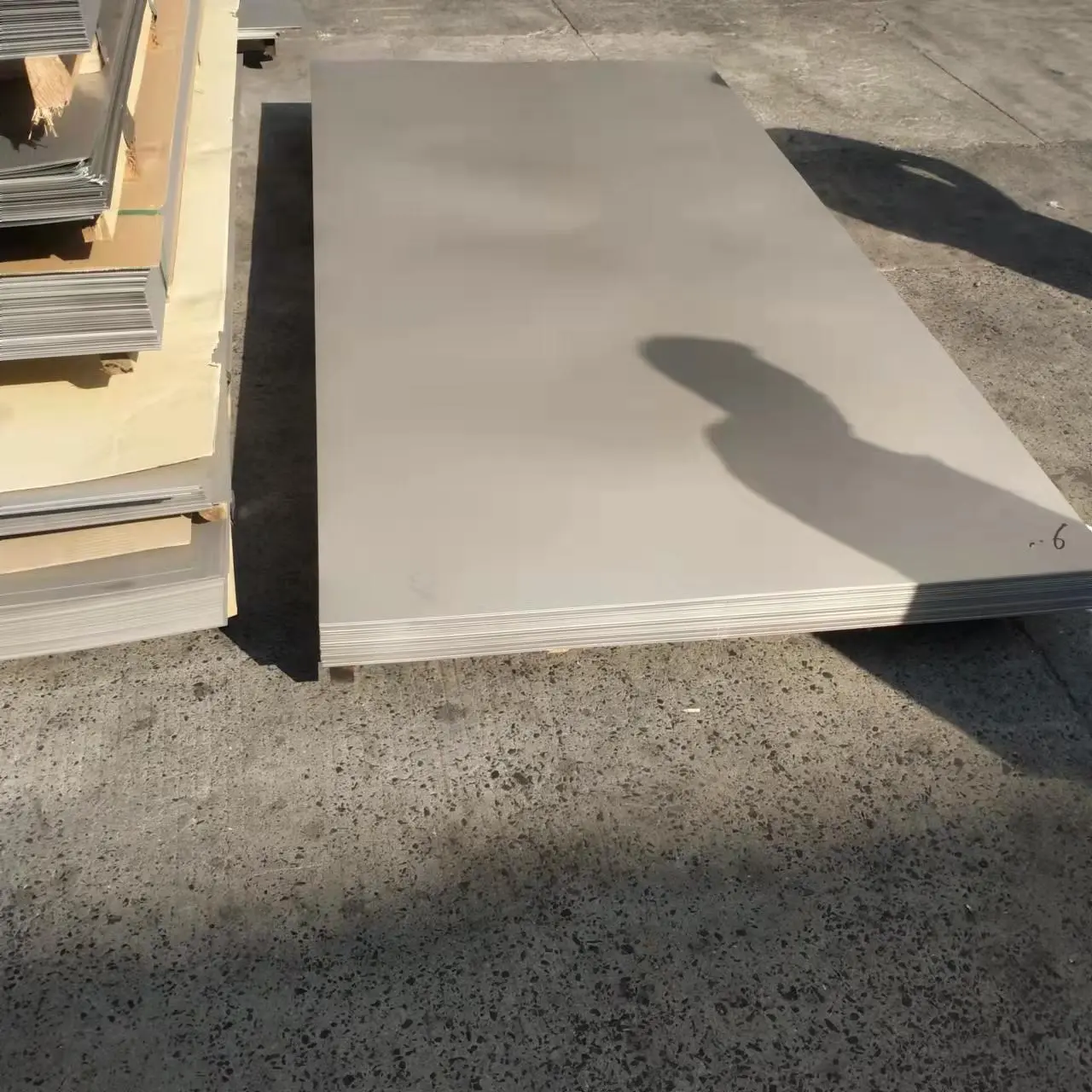

Product Display

Chemical Composition

|

C |

Si |

Mn |

Cr |

Ni |

Mo |

S |

P |

|

≤ 0.02 |

≤1.0 |

≤ 2.0 |

19.0~23.0 |

23.0~28.0 |

4.0~5.0 |

≤ 0.035 |

≤ 0.045 |

Mechanical Properties

|

Tensile Strength Kb (MPa) |

Yield Strength σ0.2 (MPa) |

Elongation D5 (%) |

Hardness |

|

≥490 |

≥220 |

≥35 |

≤ 90HRB |

Physical Performance

|

Density(g/cm³) |

Modulus of Elasticity(Gpa) |

Coefficient of Thermal Expansion(10-6/°C) |

Coefficient of Thermal Conductivity(W/m*K) |

Resistivity(ΜΩ. cm) |

|

8.0 |

195 |

15.5 |

12.0 |

94 |

Surface Selection