-

Phone

-

E-mail

-

Whatsapp

In recent years, the Square Tube Steel sector has witnessed significant advancements and innovations. Notably, the global market is projected to reach USD 100 billion by 2026, driven by increased demand across various industries. The versatility and strength of Square Tube Steel make it essential for construction, automotive, and manufacturing applications.

Industry expert John Smith, a leading analyst at Steel Innovations Group, stated, "Square Tube Steel will redefine structural design and efficiency." His insights highlight a shift toward more sustainable practices and smarter manufacturing processes involving this material. For instance, advancements in welding technology are enhancing the structural integrity of products, while improved coatings are offering better corrosion resistance.

However, challenges persist. Supply chain disruptions and a lack of skilled labor could hinder innovation in this field. As manufacturers strive to meet rising demands, there is a pressing need for investment in workforce training and material sourcing. The future of Square Tube Steel is bright, yet it requires reflection and adaptation in the face of these ongoing challenges.

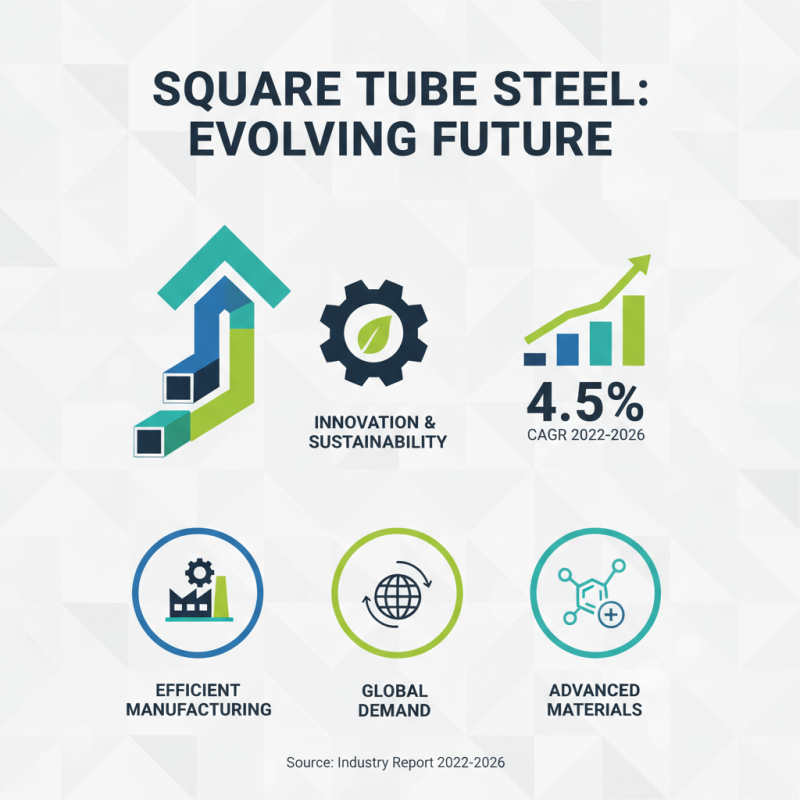

The square tube steel market is evolving. Innovative materials and technologies are shaping its future. According to a recent industry report, the global square tube steel market is set to grow at a compound annual growth rate (CAGR) of 4.5% from 2022 to 2026. This trend indicates a rising demand for sustainable and efficient manufacturing practices.

Advanced techniques are being adopted. For instance, 3D printing technology is gaining traction in steel production. It allows for precise specifications and reduces material waste. The shift towards using high-strength steels is also notable. They offer better performance and weight savings. But challenges remain in processing and welding these materials effectively.

**Tip:** Consider using high-strength steel when designing structures. It can reduce overall costs.

New surface treatments enhance durability. Coatings such as galvanization and powder coating provide resistance to corrosion. However, these processes can be complex and may require careful monitoring.

**Tip:** Regularly inspect coated surfaces for wear. This ensures long-term performance.

Overall, innovation is key in square tube steel manufacturing. Embracing new technologies will lead to better products and processes. But constant evaluation is necessary. The market is dynamic and necessitates adaptive strategies.

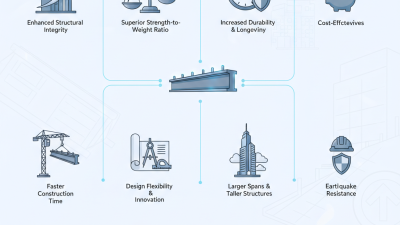

Square tube steel is increasingly popular in construction and infrastructure for its versatility and strength. A recent industry report indicates that the demand for square tube steel will grow by over 5% annually until 2026. This growth is largely driven by its applications in modular construction, where lightweight, durable materials are essential.

In urban development, square tube steel supports innovative designs. It often serves as a framework for buildings or bridges due to its excellent structural properties. Additionally, it can be recycled, making it an eco-friendlier choice. Construction managers appreciate the ease of handling and installation, which can reduce labor costs significantly. However, it is crucial to ensure quality standards in fabrication. Issues with welding or pre-treatment can compromise structural integrity.

Tips: Always verify the specifications of square tube steel to match project needs. Proper sourcing is key. Review quality control processes to avoid future problems. Lastly, consider long-term durability when choosing materials. Balancing cost and efficiency with sustainability remains a challenge in the industry.

| Application Area | Innovation Type | Sustainability Impact | Market Growth (2024-2026) |

|---|---|---|---|

| Building Frameworks | Lightweight Design | Reduction in Material Waste | 15% |

| Bridges | Corrosion-Resistant Coatings | Extended Lifespan | 20% |

| Industrial Structures | Modular Construction | Energy Efficiency | 10% |

| Towers and Masts | Smart Technology Integration | Reduced Energy Consumption | 25% |

| Transport Infrastructure | Advanced Welding Techniques | Lower Carbon Footprint | 30% |

Sustainability is becoming crucial in square tube steel production. This material is widely used in construction and manufacturing. The industry's focus is shifting towards eco-friendly practices. For instance, recycling scrap steel reduces waste and energy consumption. The process of creating square tubes can be improved with greener technologies.

Innovations like electric arc furnaces help in reducing carbon emissions. These methods are less harmful than traditional techniques. However, the high energy demand remains a challenge. Many companies still use fossil fuels in their production processes, which contradicts sustainability goals. Educating workers on best practices can drive change.

Reducing water usage in cooling processes is another key area for improvement.

Creating a circular economy for square tube steel could alleviate many environmental issues. However, implementation is often slow and costly. Collaboration between industry stakeholders is essential. Balancing efficiency with eco-friendly methods will be difficult yet vital. The road ahead may be complex, but the potential for a sustainable future is promising.

The advancements in square tube steel design and engineering are reshaping the construction and manufacturing sectors. According to recent industry reports, there has been a 25% increase in the adoption of advanced fabrication techniques over the past year. These techniques improve the efficiency and precision of fabricating square tube steel products. Their lightweight and high-strength properties are why they are favored in structural applications.

Engineers are now exploring 3D modeling and simulation technologies to enhance square tube steel applications. This digital approach allows for precise adjustments during the design process. The integration of these technologies leads to reduced waste and improved sustainability. However, challenges remain in ensuring that these innovations are accessible to smaller manufacturers. Not all companies have the resources to invest in high-tech equipment.

Sustainability is becoming a focal point, with reports suggesting a shift towards circular economy practices in steel manufacturing. Yet, many manufacturers struggle to implement these practices effectively. There’s a noticeable gap in knowledge and resources available to smaller firms. This could lead to uneven advancements in square tube steel applications across the industry. Addressing these shortcomings is crucial for broad-based innovation.

The square tube steel industry is witnessing dynamic changes as we approach 2026. Demand is rising across construction, automotive, and manufacturing sectors. These sectors require strong, lightweight materials. Innovations are necessary to keep pace with this growth. New techniques in production processes may enhance strength and reduce material waste.

Market conditions are also evolving. Environmental concerns are influencing the choice of materials. Sustainability is more than a trend; it is essential. Many companies are exploring eco-friendly practices in steel production. Lower carbon emissions are vital for future projects. This shift presents unique challenges and opportunities for industry players.

However, not all changes are straightforward. The balance between cost and quality remains a concern. Supply chain disruptions can hinder progress. Companies must adapt to fluctuating raw material prices. The future is uncertain, yet exciting. Industry professionals must embrace innovation while remaining vigilant. The road ahead holds potential, but it also requires careful navigation.