-

Phone

-

E-mail

-

Whatsapp

In recent years, the demand for Cold Drawn Steel Pipe has surged across various industries. This trend is driven by the growing need for high-strength materials in construction, automotive, and energy sectors. Industry reports indicate that the global cold drawn steel pipe market is expected to grow at a CAGR of 5.2% from 2021 to 2026. This growth reflects an increasing preference for precision-engineered products.

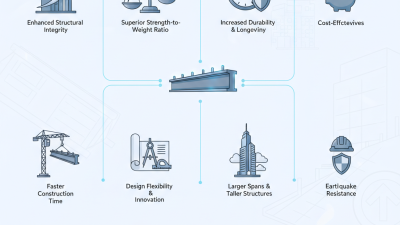

Cold Drawn Steel Pipe offers significant advantages, such as improved mechanical properties and better surface finish. These features make them suitable for critical applications, including hydraulic systems and structural components. However, manufacturers face challenges in terms of production efficiency and raw material costs. Some companies struggle to keep pace with technology advancements.

As we look toward 2026, it is essential to examine the evolving applications of Cold Drawn Steel Pipe. Industries are increasingly exploring sustainable practices. Despite the promising outlook, companies must remain adaptable. Market dynamics can shift unexpectedly, and staying aware of trends is crucial for success. The future of Cold Drawn Steel Pipe is bright, but it requires ongoing innovation and reflection on current practices.

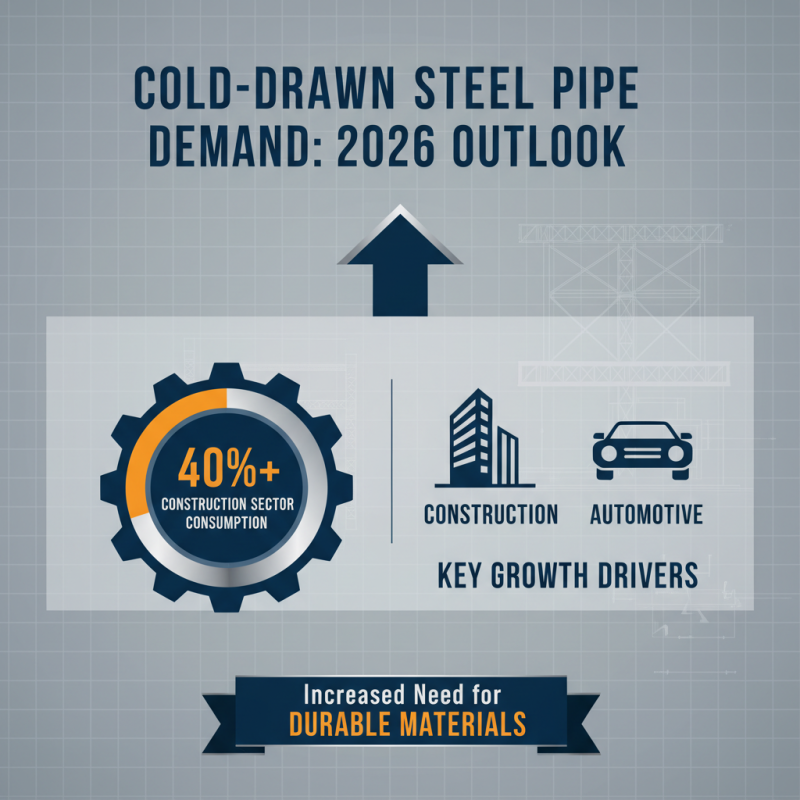

As we approach 2026, the demand for cold drawn steel pipes is set to rise dramatically. Industries such as construction and automotive are significantly driving this growth. Data from recent industry reports highlight that the construction sector alone is expected to account for over 40% of cold drawn steel pipe consumption. This shift underscores an increased need for durable materials in modern structures.

Additionally, the rise of renewable energy projects is impacting the market. Wind and solar energy developments are adopting cold drawn steel pipes for their durability in harsh environments. Reports show an anticipated increase of 25% in this sector by 2026. The versatility of cold drawn steel allows it to be used in various applications, from structural components to specialized machinery.

**Tip:** When selecting cold drawn steel pipes, consider their tensile strength and corrosion resistance. These factors will ensure longevity and performance in various environments.

Innovative manufacturing methods and technologies may create better quality products. However, not all suppliers adhere to the same standards. It's vital to scrutinize suppliers for quality assurance measures. This process helps avoid potential pitfalls in sourcing materials.

Cold drawn steel pipes are gaining traction in various industries. The manufacturing techniques have evolved significantly. Innovations in this field focus on enhancing strength and reducing defects. Cold drawing improves dimensional accuracy. This technique also enhances mechanical properties, making the pipes more reliable.

Tips: Always consider the pipe's end use. Different applications require specific properties. Assess the necessary strength and weight factors. Knowing these can lead to better choices.

Automation plays a vital role in modern production. Advanced machinery can process pipes with minimal human intervention. This leads to consistent quality but may overlook some traditional craftsmanship. While automation boosts efficiency, it can lack the personal touch. Balancing technology and craftsmanship remains a challenge.

Another noteworthy aspect is material selection. The right alloy compositions can make or break the integrity of the pipes. Engineers should not underestimate the impact of minor ingredients. Small variations can lead to significant changes in performance. Reflecting on past mistakes can guide better decisions in material choices.

This chart illustrates the projected usage percentage of cold drawn steel pipes across various industries in 2026. The construction sector leads with the highest usage, followed by automotive and oil & gas sectors.

Sustainability is shaping the future of cold drawn steel pipe applications. Many industries are shifting towards eco-friendly practices. This transition is driven by the need to reduce carbon footprints and enhance resource efficiency. Cold drawn steel pipes offer unique advantages in this scenario. They are durable, lightweight, and can be recycled easily, which makes them ideal for sustainable projects.

Innovative designs in cold drawn steel pipes are beginning to focus on performance and environmental impact. For instance, some companies are exploring coatings that reduce corrosion, extending the lifecycle of the pipe. This not only saves resources but also reduces waste. However, we must reflect on the energy consumed in the production process. Even with advances, there is still room for improvement.

Moreover, the growing demand for green infrastructure emphasizes the need for more sustainable materials. The construction industry is increasingly using these pipes in energy-efficient buildings and renewable energy projects. Yet, challenges remain. Balancing cost-effectiveness with eco-friendly innovations is crucial. As we look ahead, the path towards sustainability in cold drawn steel pipes will require continuous effort and adaptation.

| Application Area | Trend Type | Sustainability Influence | Market Growth (%) |

|---|---|---|---|

| Construction | Green Building Initiatives | Use of recycled materials | 15% |

| Automotive | Lightweight Design | Reduction in fuel consumption | 10% |

| Energy | Renewable Energy Sources | Lower emissions in production | 20% |

| Infrastructure | Smart Infrastructure | Increased efficiency and safety | 12% |

| Manufacturing | Circular Economy Models | Recycling and reusing materials | 18% |

Cold drawn steel pipes offer unique advantages compared to other steel types. Their manufacturing process involves elongating the metal at room temperature, creating a tighter tolerance and a finer surface finish. This results in greater strength and rigidity. According to the North American Steel Alliance, cold drawn steel pipes can be up to 20% stronger than extruded pipes. The efficiency of these pipes makes them ideal for demanding applications.

In sectors like automotive and construction, cold drawn pipes are highly valued. They can withstand high pressures and extreme environments. Research indicates that over 30% of cold drawn steel pipe production serves the automotive sector, addressing the need for lightweight yet strong materials. However, the initial cost can be a drawback. Some manufacturers opt for cheaper alternatives, like welded or seamless pipes, which, in terms of strength, may not match the properties of cold drawn variants.

Despite their advantages, cold drawn steel pipes require more energy during production, raising environmental concerns. The U.S. Department of Energy notes that cold working processes consume 15% more energy than traditional methods. This energy cost needs to be factored in when choosing materials. Manufacturers must balance strength with sustainability, a challenge for the evolving steel industry.

Cold drawn steel pipes are set to see a significant growth in various applications by 2026. Industries like

construction, automotive, and manufacturing rely heavily on

the strength and durability of these pipes. The demand for lightweight yet robust materials is increasing. This trend is driven by innovations aimed at enhancing performance.

The global shift towards sustainable practices also plays a role.

Tips: Always assess the specific requirements of your project. Cold drawn steel pipes vary in size and strength.

Matching the right material to your application ensures optimal performance.

The opportunity for growth also entails challenges. Not all manufacturers meet quality standards.

Vigilance is essential. You may need to evaluate multiple suppliers.

The focus should be on reliability and consistency.

Moreover, adapting to changing regulations and standards requires ongoing attention.

Staying informed about industry developments can guide strategic decisions.

Knowledge gaps can lead to oversights that might affect project outcomes.

It's crucial to reflect on the implications of such decisions in business operations.