-

Phone

-

E-mail

-

Whatsapp

Alloy Steel Bar plays a crucial role in various industrial applications. Its unique properties make it suitable for many fields. John Smith, an expert in materials science, notes, “Alloy Steel Bar is essential for enhancing performance in demanding environments.”

This type of steel bar is known for its strength and resistance to wear. Industries like construction, automotive, and aerospace rely heavily on it. In construction, it provides structural integrity. In automotive manufacturing, its durability can improve vehicle safety and performance.

However, the production of Alloy Steel Bar is not without challenges. The process requires precision and quality control. Any defects can lead to failures in critical applications. The industry continually strives for improvement, focusing on better materials and methods. Ultimately, Alloy Steel Bar remains a vital element in advancing technology and industry standards.

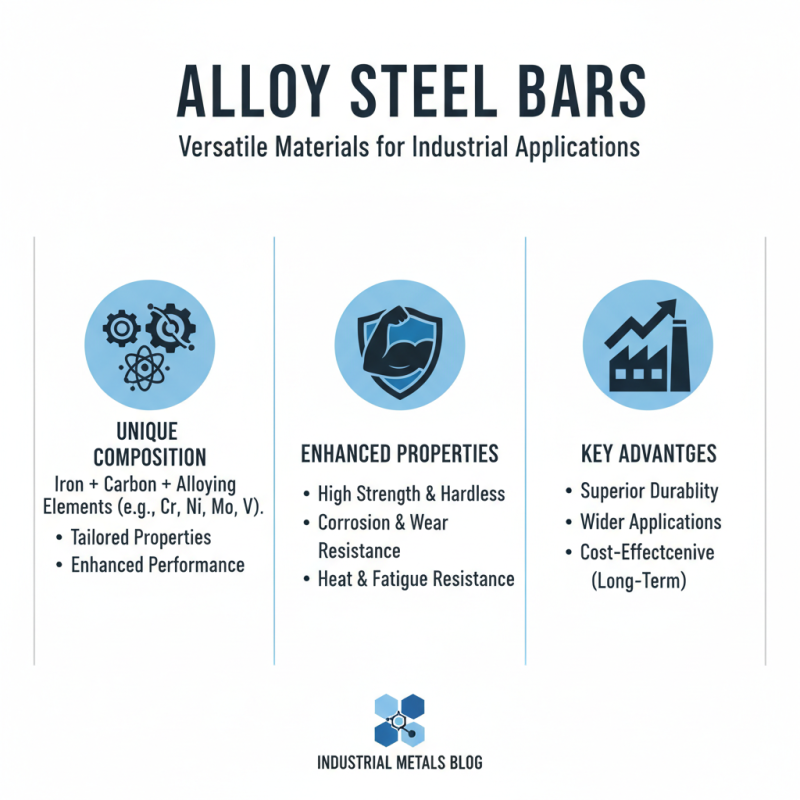

Alloy steel bars are vital in various industries. They are crafted by combining iron with specific alloying elements, such as chromium, nickel, and molybdenum. These additions enhance strength and resistance to corrosion. According to industry reports, the global demand for alloy steel is projected to reach 100 million tons by 2025, driven by sectors like construction and automotive.

The composition of an alloy steel bar varies. Typically, carbon content ranges from 0.3% to 0.6%. Higher levels of alloying elements improve hardness and toughness. This adaptability allows use in making gears, shafts, and pipelines. Interestingly, while these bars exhibit superior toughness, they may also present challenges in machinability and weldability.

Alloy steel bars find their applications in various fields, including structural engineering and manufacturing. They help in building robust frameworks. Yet, some grades can be prone to cracking under extreme conditions. As the industry grows, there's a need to address these performance challenges, ensuring product reliability and safety.

Alloy steel bars are known for their unique properties, which stem from the alloying elements they contain. These bars are typically composed of iron, carbon, and other elements such as manganese, chromium, and nickel. These additions enhance strength, toughness, and hardness, making them suitable for a variety of applications. According to industry reports, alloy steel bars can exhibit tensile strengths from 60,000 to over 200,000 psi, depending on their composition.

The significance of alloy steel bars in industry cannot be overstated. They are crucial in manufacturing components for the automotive and aerospace sectors. Fatigue resistance is essential in these applications, and alloy steel bars often outperform standard carbon steels. Certain grades perform well under high temperatures, which makes them ideal for engine parts. However, challenges remain. Some types may be more prone to corrosion if not properly treated.

Another dimension to their industrial usage is the need for careful selection based on specific requirements. Not all alloy steels are equal. The addition of elements can significantly modify properties, which is sometimes misunderstood. A misstep in material choice can lead to mechanical failures. As industries evolve, understanding alloy steel bars' properties becomes increasingly vital for ensuring safety and efficiency.

This chart illustrates the distribution of alloy steel bar applications across various industries. The construction sector utilizes 30% of alloy steel bars, followed by automotive at 25%, aerospace at 20%, manufacturing at 15%, and oil & gas at 10%. These percentages reflect the significant role that alloy steel bars play in enhancing strength and durability in diverse industrial applications.

Alloy steel bars are widely used in various industries due to their enhanced mechanical properties. Different types of alloy steel bars are tailored for specific applications. A common variant is chromium-molybdenum steel, often used in heavy machinery. This type offers superior strength and resistance to wear, making it ideal for construction and mining.

Another notable type is nickel alloy steel, which provides excellent toughness and ductility. This steel is crucial in the automotive and aerospace sectors, where components must endure extreme conditions. Data from industry reports indicate that the demand for alloy steel bars in the automotive sector is expected to grow by 5% annually until 2025.

Tips: Always consider the specific requirements of your project. Different applications may call for distinct steel grades. Ensure you understand the environmental conditions the steel will face. Misjudging this could lead to early material failure, impacting safety and performance. Keep abreast of industry trends; they can guide you in selecting the right materials.

Alloy steel bars are gaining momentum in various industrial applications. They are known for their durability and strength. The market for these bars is witnessing a surge due to advancements in manufacturing processes. Industries such as automotive, construction, and aerospace rely heavily on alloy steel bars. These sectors are constantly evolving, creating new demands.

The future trends indicate a growing preference for alloy steel bars, driven by sustainability. More companies are focusing on using recyclable materials. This shift may improve the environmental impact of production. However, challenges remain in sourcing raw materials sustainably. Additionally, some manufacturers struggle with the cost-effectiveness of producing these bars. Market volatility can also affect the prices and supply chains.

Overall, the demand for alloy steel bars shows a promising trajectory. Innovations in alloy compositions enhance their properties further. The industry must remain adaptable to market changes and shifts in consumer preferences. As technology progresses, the potential applications of alloy steel bars are expanding. Companies must stay ahead to meet these demands effectively.

| Category | Properties | Applications | Market Demand (in metric tons) | Future Growth Rate (%) |

|---|---|---|---|---|

| High Strength Low Alloy (HSLA) | High tensile strength, good weldability | Construction, automotive frames | 1,200,000 | 5.2 |

| Stainless Steel Alloy | Corrosion resistance, high durability | Chemical industries, food processing | 800,000 | 4.8 |

| Tool Steel | High hardness, excellent wear resistance | Manufacturing tools, dies | 600,000 | 3.5 |

| Carbon Steel Alloy | Good strength, moderate ductility | Transport, fabrication | 1,500,000 | 6.0 |

| Alloy Steel | Enhanced strength, toughness | Oil & Gas, pipelines | 900,000 | 4.0 |

Alloy steel bars are versatile materials, used widely in various industries. Their unique composition gives them enhanced properties, making them suitable for many applications. When compared to other steel types, alloy steel bars show significant advantages.

One key difference is strength. Alloy steels can endure high stress and resistant wear. They are commonly found in automotive parts, pipelines, and machinery components. On the other hand, mild steel lacks some of these mechanical properties, making it less suitable for demanding applications. However, mild steel is cheaper and easier to work with, appealing to certain projects.

Another important aspect is corrosion resistance. Some alloy steels contain elements like chromium and nickel. This improves their resistance to rust and oxidation. In contrast, carbon steel is more prone to corrosion, requiring protective coatings for outdoor use. While alloy steels generally provide superior performance, their higher cost can be a barrier for some businesses. Finding a balance between cost and performance often requires careful consideration.