-

Phone

-

E-mail

-

Whatsapp

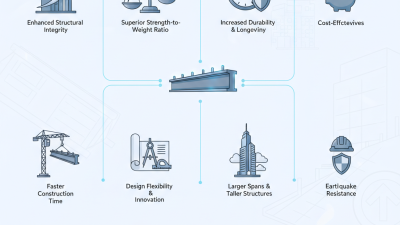

In recent years, Aluminum Steel Pipe has garnered significant attention in the construction industry. Experts emphasize its advantages over traditional materials. John Smith, a leading engineer, stated, "Aluminum Steel Pipe combines strength and lightweight properties, making it ideal for modern construction."

These pipes are known for their durability and resistance to corrosion. This means they require less maintenance. However, it's essential to consider factors like cost-effectiveness and installation processes. Many contractors still hesitate when switching from conventional materials. They often assess the long-term benefits versus the initial investment.

The versatility of Aluminum Steel Pipe can't be neglected. It's used in various applications, from structural support to plumbing. While many praise its benefits, it's crucial to reflect on the challenges faced during adoption. Educating workers on new materials is vital for smooth integration.

Aluminum steel pipes have unique advantages in construction. Their lightweight nature enhances ease of handling and installation. Workers appreciate not straining under heavy loads. This attribute also speeds up the construction process, allowing for quicker project completion. However, some may find the material less durable than expected, particularly in extreme conditions.

Corrosion resistance is another benefit. Aluminum naturally resists rust, extending the life of structures built with it. This can reduce repair and maintenance costs. Yet, in certain environments, like highly acidic areas, it may still require protective coatings. It's essential to assess the specific project conditions.

Another point to consider is cost-efficiency. While aluminum steel may be pricier upfront, its longevity often leads to lower overall expenses. This provides a solid return on investment over time. Some builders still debate its suitability compared to traditional steel. This ongoing discussion highlights the need for careful evaluation in material selection.

Aluminum steel pipes offer remarkable durability and excellent corrosion resistance, making them ideal for construction. In environments prone to moisture, corrosion can be detrimental. Reports indicate that aluminum steel pipes last up to three times longer than traditional steel when exposed to harsh conditions. This longevity reduces replacement costs and project downtime.

The lightweight nature of aluminum steel pipes also makes them easier to handle. Installation is less labor-intensive. Workers can maneuver them without heavy machinery. However, some might question the balance between strength and weight. They are strong enough for high-pressure applications yet light enough for easy transport. It's a delicate balance that not all materials can achieve.

Nevertheless, there are challenges. Aluminum steel can be more expensive upfront compared to standard steel. Some contractors may hesitate to invest initially. Yet, the long-term savings in maintenance often outweigh these costs. Proper understanding of this material can lead to better choices in construction projects. It's essential to consider both immediate and future needs when selecting materials.

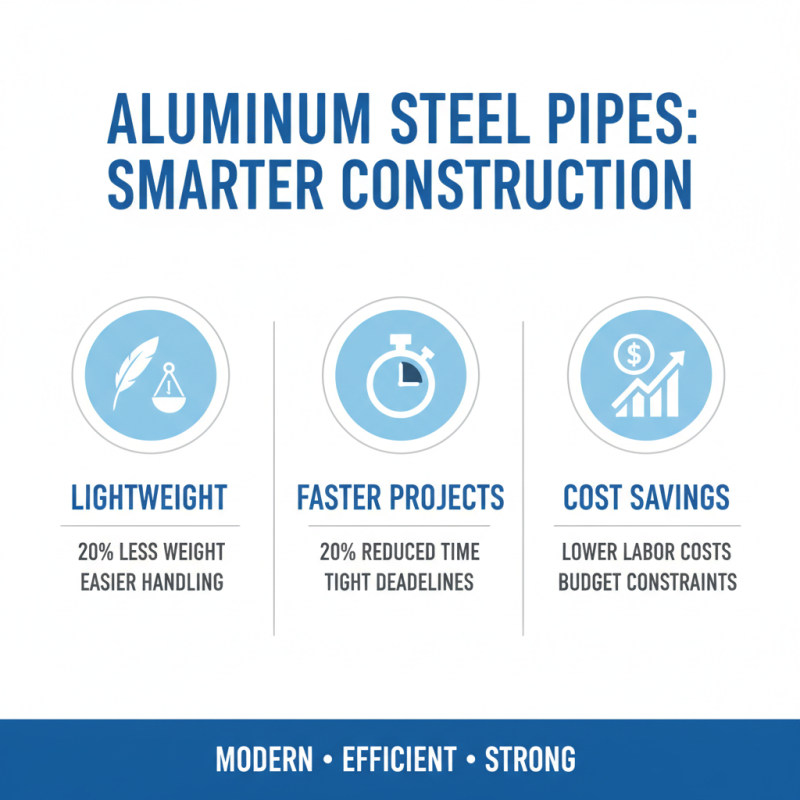

The lightweight nature of aluminum steel pipes makes them a popular choice in construction. Weighing significantly less than traditional steel, these pipes allow for easier handling and reduced labor costs. According to a report from the Construction Industry Institute, using lighter materials can lead to a 20% reduction in overall project time. This advantage is critical for tight deadlines and budget constraints.

Workers can maneuver aluminum steel pipes more easily on-site. Less weight means less physical strain, which can lead to fewer workplace injuries. In fact, studies show that construction sites with lighter materials see a drop in injury reports by up to 15%. This can contribute to a safer work environment and improve team morale. However, the benefits don’t come without considerations. Balancing strength and weight can be challenging. Some may question the durability of lighter aluminum steel pipes in harsh environments.

Despite these concerns, the adaptability of aluminum steel pipes is evident. They can be easily cut and welded, which saves time during installation. The versatility appeals to many projects, from residential to industrial builds. However, the initial costs may be higher compared to traditional materials. As construction evolves, weighing the pros and cons of aluminum steel pipes will become increasingly important.

Aluminum steel pipes have become increasingly popular in the construction industry. When considering long-term projects, one significant advantage is cost-effectiveness. Their lightweight design makes them easier to transport and install, reducing overall labor costs. This efficiency can lead to substantial savings over time.

Another important aspect is durability. Aluminum steel pipes resist corrosion, leading to lower maintenance costs. Traditional materials might require more frequent replacements. This factor adds to the overall expenses of a project. However, aluminum steel pipes might initially be pricier. It's essential to compare long-term expenses rather than just initial costs.

Moreover, these pipes can contribute to sustainable construction practices. Their recyclability adds value over the lifespan of a project. While they might appear less robust than traditional materials, careful design and engineering can ensure strength without added weight. Still, some projects may overlook these benefits. It’s crucial to analyze all factors before making material choices.

Aluminum steel pipes offer remarkable versatility in construction. These pipes are lightweight yet strong, making them ideal for various applications. They fit seamlessly into both residential and commercial projects, from frameworks to piping systems. Their resistance to corrosion extends their lifespan. However, one might question whether they can handle extreme weather conditions effectively.

In structural applications, aluminum steel pipes provide excellent support. They are often used in scaffolding and temporary structures. Their ease of installation saves time on the job site. But, challenges may arise in welding and joining techniques. Proper methods must be employed to ensure integrity and safety. Additionally, innovative designs are possible with these materials, allowing for flexibility in architecture.

Moreover, these pipes contribute to energy efficiency. Their lightweight nature reduces transportation costs and energy use during construction. Yet, some may argue that traditional materials still hold an edge in certain scenarios. Continuous research and testing are essential to explore their full potential. Engaging with experts can lead to better outcomes.

| Benefit | Description | Applications | Durability |

|---|---|---|---|

| Lightweight | Easy to handle and transport, reducing transportation costs. | Structure frameworks, scaffolding. | High corrosion resistance ensures longevity. |

| Corrosion Resistance | Resists oxidization, prolonging the lifecycle of installations. | Piping systems, outdoor installations. | Suitable for various environments, including coastal areas. |

| Strength | Provides excellent structural integrity while being lightweight. | Structural beams, reinforcements. | Long-lasting performance under heavy loads. |

| Versatility | Can be used in a wide range of building applications. | Pipes, frames, and robotics. | Effective in diverse settings. |

| Ease of Maintenance | Requires minimal upkeep due to its durability. | Maintenance-focused structures, HVAC systems. | Lower maintenance costs over time. |

| Cost-Effectiveness | Offers great value due to its durability and lightweight design. | Commercial and residential buildings. | Cost savings through longevity. |

| Thermal Conductivity | Conducts heat well, useful in temperature-controlled environments. | Heating and cooling systems. | Enhanced energy efficiency. |

| Sustainability | Recyclable material, promoting environmental friendliness. | Eco-friendly construction projects. | Supports sustainable practices. |

| Aesthetic Appeal | Provides a modern and sleek look to structures. | Architectural details, facades. | Visually appealing long-term solutions. |

| Safety | Lower risk of rust and fire hazards. | Safe constructions, relevant in heavy machinery. | Increases safety in construction. |