-

Phone

-

E-mail

-

Whatsapp

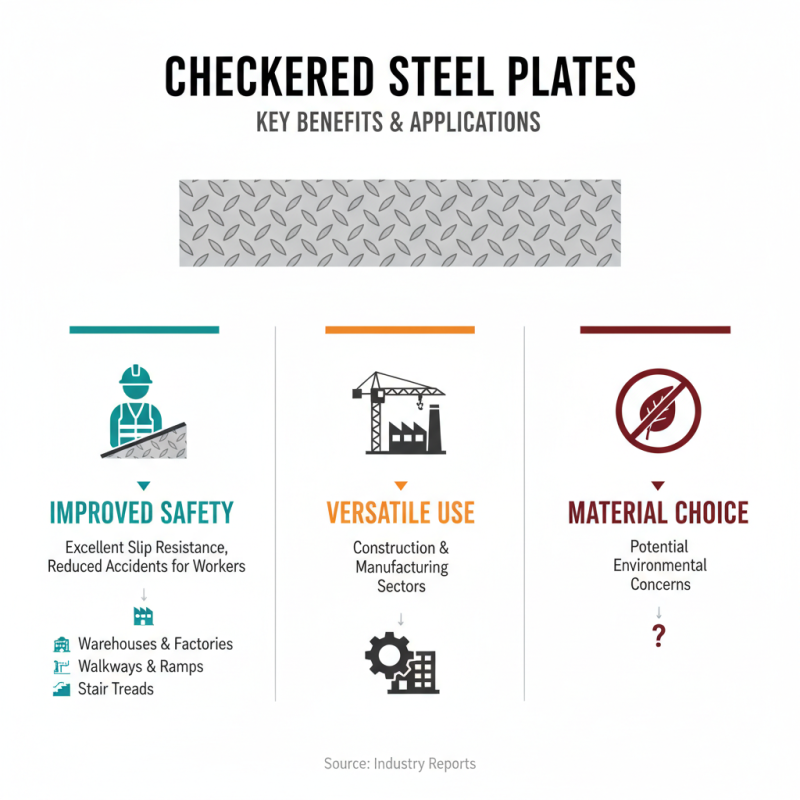

The versatility of Checkered Steel Plate makes it a prominent choice in various industries. According to a recent market research report, the global steel plate market is expected to reach $200 billion by 2026. This growth indicates a rising demand for materials that combine strength and safety.

Checkered Steel Plate offers unique benefits, such as anti-slip surfaces, enhancing safety in high-traffic areas. The patterns create friction, reducing accidents in places like warehouses and construction sites. These plates are often used in floors, ramps, and staircases, demonstrating their practicality in real-world applications.

However, despite their advantages, there are challenges to consider. Some industries may overlook the long-term costs associated with maintenance. Understanding the nuances of Checkered Steel Plate usage can lead to improved decision-making. Awareness of potential limitations can guide professionals in selecting the best options for their specific needs.

Checkered steel plates stand out in many industries. Their unique pattern provides excellent traction. This makes them ideal for flooring in warehouses and factories. In high-traffic areas, slip resistance is crucial. Workers feel safer on checkered surfaces. These plates also resist wear and tear, reducing maintenance costs over time.

In construction, checkered steel plates offer strength and durability. They are often used in stair treads and walkways. However, in some cases, the installation can be tricky. Precision is needed to ensure safety and effectiveness. Moreover, while they are robust, these plates can be heavy. This sometimes complicates transportation and setup.

The automotive industry also benefits from using checkered steel. They are found in ramps and protective barriers. Their ability to handle heavy loads is impressive. Yet, not every application is suitable. It is essential to assess specific needs before choosing materials. Sometimes, the aesthetic appeal can be overlooked. The pattern may not fit all design visions.

Checkered steel plates offer significant advantages, particularly in safety and durability. These plates are designed with a raised diamond pattern, which provides excellent grip. According to a recent industry report, surfaces with checkered patterns can reduce slip and fall incidents by up to 40%. This is crucial in environments such as warehouses and industrial settings, where safety is paramount.

Moreover, checkered steel plates are known for their resistance to wear and corrosion. The durability of these plates means they require less frequent replacement. They can withstand heavy loads and harsh conditions. A study shows that using these plates can extend the lifespan of flooring systems by up to 30%. However, installation can pose challenges. Proper alignment and securing methods are essential to maximize their benefits. Neglect in these areas can lead to safety hazards.

In addition, the aesthetic appeal of checkered steel plates is noteworthy. They can enhance the visual aspect of industrial spaces while providing functionality. However, some manufacturers highlight the need for regular maintenance to preserve this appeal. Dirt and grime can accumulate, undermining their efficiency and look. Addressing this requires consistent effort, but the benefits often outweigh the drawbacks, particularly when focusing on safety and durability.

Checkered steel plates offer unique advantages over traditional steel plates. Their surface features a raised pattern, which enhances traction significantly. This makes them ideal for platforms and walkways. In contrast, traditional steel plates can be slippery, especially when wet. The risk of slipping increases in various environments.

Another point of comparison lies in durability. Checkered steel plates resist dents and scratches better than their flat counterparts. This strength is crucial in heavy traffic areas. However, they can be heavier, which may complicate installation processes. It's crucial to weigh these factors when selecting the right type for a project.

Aesthetics and functionality also come into play. Some may find the patterned look of checkered plates appealing. They can add an element of design to utility spaces. Nevertheless, not everyone appreciates the aesthetics. Some projects may require a sleek and smooth finish, which traditional plates provide. Balancing these considerations can be challenging yet essential.

Checkered steel plates have gained significant traction in both construction and manufacturing sectors. Their textured surface provides excellent slip resistance, making them ideal for flooring applications. Workers benefit from improved safety in warehouses and factories, reducing the risk of accidents. These plates are often used in creating walkways, ramps, and stair treads. However, the choice of material may not always meet environmental standards.

In construction, checkered steel plates are used for structural reinforcement. Their strength adds durability to buildings and bridges. Yet, there can be concerns about the weight of these plates. Heavier plates may increase transportation costs and complicate installation processes. It's essential to consider the overall design requirements to avoid unnecessary complications.

Manufacturers are also exploring innovative uses. With growing interest in aesthetics, checkered steel plates can enhance visual appeal. Decorative applications in furniture or signage are emerging trends. Still, the balance of function and style is challenging. It invites reflection on how to best utilize these materials without compromising their core benefits.

Innovations in checkered steel plate usage are unfolding rapidly. This material is favored for its slip-resistant properties, vital in construction and transportation sectors. A recent industry report indicates that the global demand for checkered steel plates is expected to reach 5 million tons by 2026. This growth highlights the increasing reliance on safer design in industrial applications.

Emerging technologies bring both promise and challenges. Advanced manufacturing processes, such as laser cutting, enhance production efficiency. However, these methods require significant investment. Many small manufacturers struggle to keep pace with technological trends. Additionally, sustainability is becoming crucial. The industry faces pressure to adopt greener practices, but the transition can be slow and costly.

A report from Market Research Future highlights a projected 4% CAGR in the checkered steel plate market. This growth stems from rising construction activities globally. Yet, the reliance on outdated manufacturing techniques may hinder progress. Companies need to adapt or risk losing market share. Addressing these imperfections is crucial for the future of this vital material.