-

Phone

-

E-mail

-

Whatsapp

Choosing the right Nickel Alloy Steel Pipe for your project can be daunting. Many factors must be considered, including the desired application and environmental conditions. Nickel alloy steel pipes offer exceptional resistance to corrosion and high temperatures. However, not all nickel alloys are created equal.

In some cases, the choice may seem straightforward, but complications arise when specific requirements clash. For instance, a project requiring high durability might struggle with weight limitations. Understanding the differences between various alloy compositions is crucial. Features such as tensile strength, weldability, and fatigue resistance can vary significantly.

Additionally, sometimes trying to save costs can backfire. Opting for a cheaper option may lead to more substantial issues later. It’s essential to evaluate long-term performance over initial expenses. Ultimately, investing time in selecting the right Nickel Alloy Steel Pipe is vital for the success of your project.

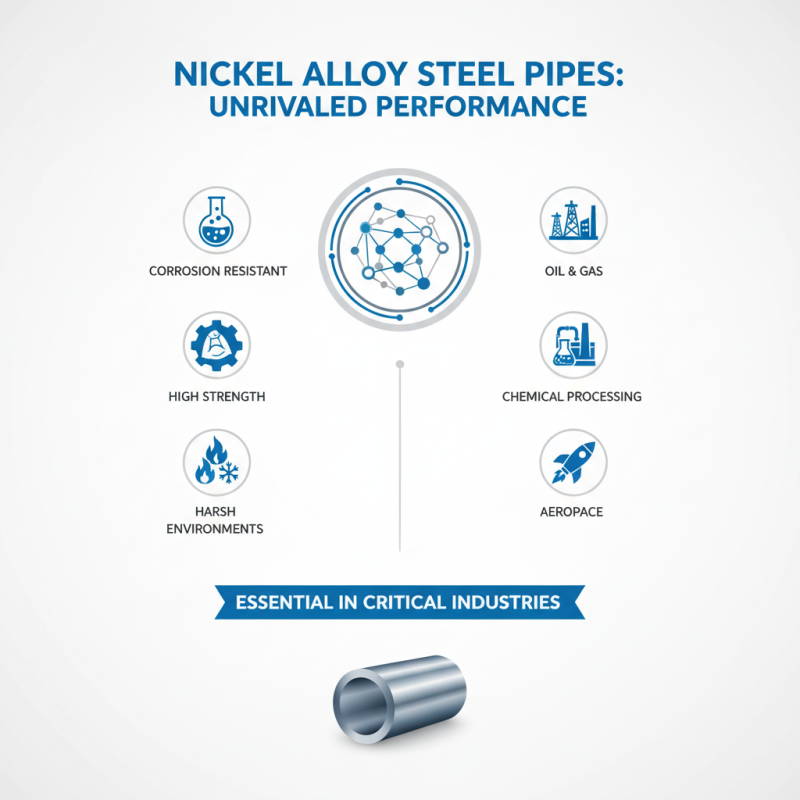

Nickel alloy steel pipes are essential in various industries. They are known for their corrosion resistance and high strength. These pipes are often used in chemical processing, oil and gas, and aerospace applications. The unique properties of nickel alloys make them ideal for harsh environments.

Understanding the specific application of these pipes is crucial. For instance, in the oil and gas sector, pipes need to withstand high pressures and temperatures. Choosing the wrong alloy can lead to failure. Some projects might benefit from the flexibility of inconel or hastelloy. Evaluating the operating conditions is vital to avoid costly mistakes.

Manufacturing processes can also impact performance. Weldability might vary between different nickel alloys. Paying attention to these details ensures the final product meets safety and durability standards. However, not every project requires the same type of pipe. There’s a risk in assuming one size fits all. Careful considerations and thorough tests can lead to better choices and project success.

When choosing a nickel alloy steel pipe, understanding key properties is crucial. Nickel alloys are known for their excellent corrosion resistance. For instance, data from NACE International confirms that nickel-containing alloys excel in harsh environments, especially in acidic conditions. This makes them ideal for chemical processing applications.

Temperature resistance is another vital property. Nickel alloys can withstand high temperatures without losing strength. A report by ASTM International highlights that these materials retain their toughness even at elevated temperatures. This makes them suitable for industries like aerospace and power generation.

However, there are challenges. Not all nickel alloys perform the same way in every application. Some may not offer the required ductility. This emphasizes the importance of selecting the right grade for your specific needs. Evaluating mechanical properties, such as tensile strength and yield strength, cannot be overlooked. This process often involves trade-offs in overall performance. You may find one alloy excels in corrosion resistance but falls short in mechanical strength.

When selecting nickel alloy steel pipes, fabrication processes are crucial. Different methods can impact the pipe's strength and durability. Common processes include welding, bending, and machining. Each method has its strengths and weaknesses. For example, welded joints may be less durable than seamless pipes. But they are often more cost-effective. Consider your project needs carefully.

Thickness requirements also play a significant role in pipe selection. Thicker pipes can withstand higher pressures and temperatures. However, they are usually heavier and more challenging to work with. Assess your project's demands. Will the pipe face extreme conditions? Will it be easy to handle? These questions can guide your choice. Sometimes, a thinner pipe may suffice. It depends on the application and environment.

Ultimately, every project is unique. The perfect pipe for one situation may not suit another. It’s essential to evaluate all aspects before making a final decision. Reflecting on your needs will lead to better outcomes. Every material choice should align with both performance and practicality.

| Property | Value | Comments |

|---|---|---|

| Alloy Type | Inconel 625 | Excellent corrosion resistance |

| Thickness | 0.5 - 2.0 inches | Choose based on pressure requirements |

| Temperature Range | -250°C to 1000°C | Applicable for deep freezing to high heat |

| Fabrication Method | Welding & Machining | Consider weldability and machinability |

| Applications | Aerospace, Chemical Processing | Suitable for extreme environments |

When selecting the right nickel alloy steel pipe, cost and availability are key. Nickel alloys are widely used in industries like aerospace and chemical processing. According to the Global Nickel Alloy Steel Pipe Market report, prices vary significantly. For example, alloy 625 can cost up to 30% more than 304 stainless steel. This disparity is essential to consider when budgeting for projects.

Availability is another critical factor. Some alloys, like Inconel 718, face supply chain challenges due to their complex production process. Reports show that lead times can extend up to 12 weeks. In contrast, more common nickel alloys may be readily accessible from numerous suppliers. This can influence project timelines and budgets.

Tip: Always verify current market trends. Prices fluctuate based on global nickel production and demand.

Choosing the right alloy involves understanding these aspects. Each project has unique needs. Don’t overlook the potential costs associated with delays in material sourcing or changes in design. Balancing cost with availability could determine the success of your project.

Tip: Consider local suppliers for better availability. This might reduce lead times and shipping costs, ensuring your project stays on track.

When selecting a nickel alloy steel pipe, environmental considerations play a crucial role. The location of your project can significantly affect material performance. High humidity areas may lead to corrosion, while exposure to harsh chemicals can weaken the pipe. It's essential to assess the environment thoroughly before making a decision.

Tips: Always consider corrosion resistance when choosing materials. Conduct a risk assessment to identify potential environmental threats.

Durability is another key aspect. Nickel alloys are known for their strength and resilience. However, not all alloys are created equal. Some may fail under unforeseen conditions. Over time, pipes can experience wear and tear. Regular inspections are necessary to ensure longevity. Remember, choosing the right alloy can prevent costly repairs in the future.

Tips: Check the specifications of alloys carefully. Create a maintenance schedule for regular inspections.