-

Phone

-

E-mail

-

Whatsapp

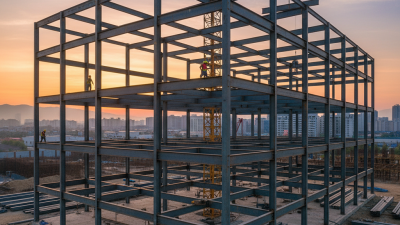

Choosing the right alloy steel bar for your project is crucial. The global alloy steel market is expected to reach $158.56 billion by 2026, driven by industrial growth. Alloy steel bars are essential in construction, automotive, and energy sectors. They provide strength, durability, and resistance to wear.

However, the selection process can be challenging. Different projects require different specifications. For instance, heat-treated alloy steel bars may be needed for high-stress applications. Understanding the properties of various alloys matters. Data from industry reports suggest that misselection can lead to project failures and financial losses.

Many manufacturers offer alloy steel bars with distinct features. Consider tensile strength, hardness, and corrosion resistance. Evaluate how these factors align with your project needs. Often, overlooked details can result in significant issues later on. Reflection on past decisions can guide better choices in the future. Choose wisely to avoid common pitfalls.

Choosing the right alloy steel bar begins with understanding its composition. Alloy steels consist of iron, carbon, and other elements. Common elements include manganese, nickel, and chromium. Each addition modifies the steel's properties. For example, manganese increases hardness and strength. Nickel enhances toughness, while chromium improves corrosion resistance.

The properties of alloy steel bars vary widely. Some are designed for high-temperature applications. Others excel in low-temperature environments. It's crucial to match the steel type to your project needs. Consider factors like tensile strength and ductility. However, the selection process could be challenging. Certain alloys may be over-engineered for simple applications. This can lead to increased costs without added benefits. Analyzing your project's requirements can help avoid such pitfalls.

Lastly, don't underestimate the impact of fabrication methods. The way an alloy steel bar is shaped affects its final properties. Improper handling can lead to defects. Always reflect on how these factors align with your project's goals. Making informed choices requires careful consideration of these aspects.

| Alloy Type | Composition | Properties | Applications |

|---|---|---|---|

| 4140 | 0.38-0.43% C, 0.75-1.00% Cr, 0.15-0.25% Mo | High strength, toughness, wear resistance | Gear shafts, axles, and high-stress components |

| 4130 | 0.28-0.33% C, 0.70-0.90% Cr, 0.15-0.25% Mo | Good weldability, ductility, and strength | Aerospace, automotive, and structural applications |

| 8620 | 0.18-0.23% C, 0.40-0.60% Ni, 0.15-0.25% Mo | High hardenability, good machinability | Gears, crankshafts, and automotive components |

| S7 | 0.50-0.60% C, 0.40-0.60% Cr, 1.25-1.75% Mn | Excellent shock resistance and toughness | Tooling, impact tools, and dies |

When choosing alloy steel bars, several key factors come into play. The specific application often dictates the required properties. Alloy steel's versatility lies in its varying compositions, which can affect hardness, tensile strength, and corrosion resistance. According to the American Iron and Steel Institute, over 80% of steel is alloyed for enhanced performance across different sectors, like automotive and construction.

Understanding mechanical properties is crucial. For instance, high-strength alloy steels commonly range from 500 to 1,000 MPa in tensile strength. This data emphasizes the importance of selecting the right grade based on load requirements. Additionally, the environment can impact durability. Factors such as temperature fluctuations and exposure to corrosive elements can weaken poorly chosen materials.

It's also essential to consider the bar's diameter and surface finish. A surface that is too rough can lead to stress concentrations. Conversely, a smoother surface can enhance fatigue resistance. In a recent study, nearly 30% of failures were linked to inadequate surface treatment. It illustrates the need for attention to detail in all selection aspects. Being informed about these factors helps avoid costly oversights in project outcomes.

When selecting alloy steel bars, understanding the various grades is crucial. Common grades include 4140, 4130, and 8620. Each has unique properties. For instance, 4140 is known for its high tensile strength and wear resistance. It's often used in automotive components. Meanwhile, 4130 is lighter but still has good strength and weldability, making it a favorite in the aerospace sector.

The applications vary significantly. 8620, for example, has excellent case hardening abilities. It’s widely used in gears and heavy-duty machinery. According to industry reports, 4140 can achieve a yield strength of over 60,000 psi, while 4130 typically maxes out around 40,000 psi. This makes the choice dependent on your project requirements.

Tip: Think about the environmental conditions your project will face. High corrosion could dictate a different grade.

It's important to consider that not all grades are suitable for every application. Sometimes, the initial choice may not work. Testing samples can provide better insights. Communicate with your supplier about application needs and physical conditions.

Tip: Don’t hesitate to seek expert advice. A small mistake in grade selection can lead to project delays or failures.

When selecting an alloy steel bar, understanding mechanical properties is crucial.

Strength determines how much load the steel can handle.

Ductility indicates how much the material can deform before breaking.

Hardness measures resistance to surface deformation.

These factors together influence the bar's suitability for different applications.

Here are some tips. Consider the environment where the steel will be used.

High temperatures might lower strength. A more ductile bar can absorb energy during impacts.

Think about the processing method, as some steel types can be harder to machine.

Also, testing the steel properties is essential.

Testing can reveal unexpected results. Don’t just rely on data sheets.

Sometimes, the actual performance differs from the expected metrics.

Circumstances in real-world applications can highlight flaws in assumptions.

Always plan for variability in your project.

When selecting alloy steel bars, cost is a critical factor. A recent industry report indicates that alloy steel prices can range from $0.50 to $2.50 per pound. This price variability depends on composition, heat treatment, and quantity. Quality often demands higher prices; however, compromising on quality can lead to increased costs in the long run due to failures or replacements.

Understanding your project's specific requirements is vital. For instance, high-tensile strength applications may necessitate a more expensive alloy. A project needing 15 tons of high-strength steel might incur costs around $30,000 to $75,000, depending on specifications. Conversely, neglecting to account for life-cycle costs is common, which could lead to budget overruns.

Moreover, evaluating suppliers is crucial. Some offer lower prices but may compromise on material quality. The 2022 Steel Procurement Survey found that 40% of companies faced additional costs due to quality-related returns. It's a stark reminder that balancing quality and budget isn’t just a financial decision; it directly impacts project timelines and success rates.

This chart illustrates the cost per ton of various alloy steel bars, showcasing the balance between quality and budget for procurement.