-

Phone

-

E-mail

-

Whatsapp

Choosing the right Square Tube Steel is crucial for any project. In construction, the right choice impacts strength and stability. According to the American Institute of Steel Construction, roughly 50% of all structural steel is used in commercial buildings. This shows how vital proper selection is.

Square Tube Steel has various sizes and grades. Each serves different purposes. The wrong choice can lead to project delays and increased costs. A report from the Steel Construction Institute notes that wrong material specifications cause 30% of construction delays. This highlights the necessity of informed decisions.

Understanding your project’s requirements is key. Factors like load-bearing capacity and environmental conditions matter. It’s also important to reflect on cost vs. quality. Often, budget constraints lead to compromises that can weaken structural integrity. Balancing quality with cost is a challenging yet essential task.

Square tube steel is an essential material in various construction and fabrication projects. It offers a unique combination of strength, durability, and versatility, making it suitable for a wide range of applications. According to recent industry reports, the global square tube steel market is projected to reach $85 billion by 2027. This growth is spurred by an increasing demand in sectors such as automotive, construction, and manufacturing.

When considering the right square tube steel for your needs, understanding its specifications is crucial. Square tubes come in various sizes, thicknesses, and grades. Typical dimensions range from 1 inch to 12 inches, and wall thickness can vary widely. One tip: always check a supplier's certifications. Compliance with ASTM standards ensures that the material meets industry benchmarks for quality and safety.

Choosing the right steel can be tricky. Factors such as corrosion resistance and material grades play a significant role. Ensure that you consider the environment where the steel will be used. For instance, projects in coastal areas require higher corrosion resistance. This local knowledge can shape your choice. Remember: it’s okay if you don’t get it right the first time. Testing prototypes can provide insight into what works best for your specific project.

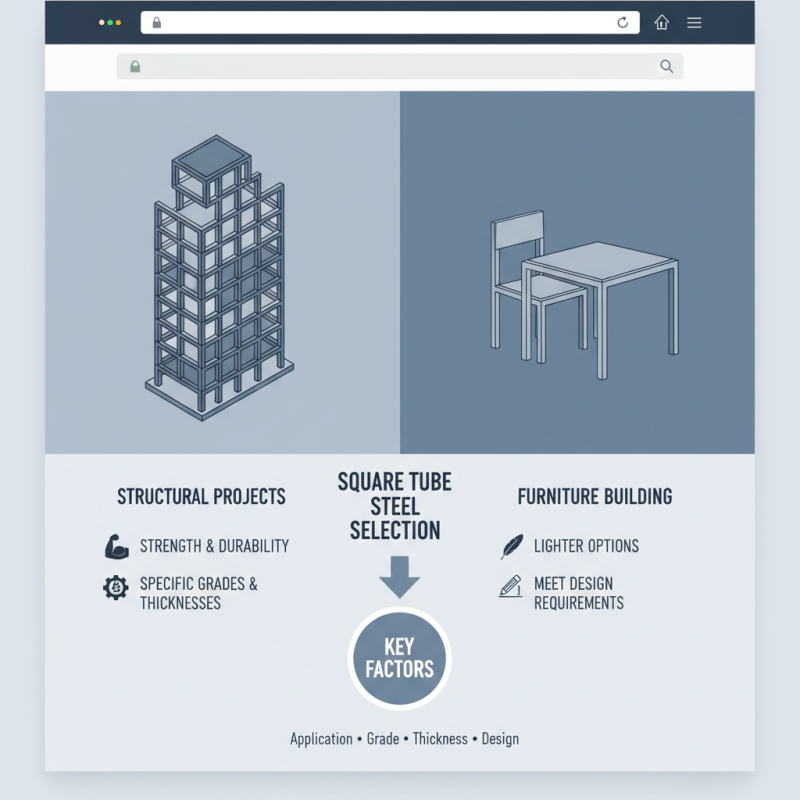

When selecting square tube steel, several factors significantly impact the decision. The application plays a crucial role. Structural projects require specific grades and thicknesses for strength and durability. For furniture building, lighter options may suffice, but they should still meet design requirements.

Dimensions are equally important. Width and height influence both weight and stability. Consider how the material will interact with other components. Sometimes, the fit may seem perfect on paper but fail in practical applications. Weight distribution is a factor often overlooked.

Finally, think about intended use and environmental exposure. Some projects require corrosion-resistant finishes. Be mindful of how the steel will age. Aesthetic choices might clash with functionality. Balancing form and function takes thought. Every choice matters, even the small ones. Prioritize your project needs and reflect on your decisions carefully.

Choosing the right square tube steel for your project can be challenging. Different grades and types serve specific purposes. You need to consider strength, corrosion resistance, and thickness. Mild steel is affordable and versatile. It’s a good choice for many structural applications. However, it can rust if not properly treated.

Stainless steel square tubes offer better durability. They resist corrosion, making them suitable for outdoor use. This type is heavier and often more expensive. Aluminum tubes are lightweight and easy to work with. They are not as strong but can be ideal for projects requiring light structures.

You might find it tough to balance quality and cost. Your project’s requirements can lead to confusion. Sometimes, you may invest in an expensive option without clear advantages. Make sure to assess the specific needs of your application. Each grade has its pros and cons that need careful consideration.

When selecting square tube steel, measuring and sizing requirements are crucial. Accurate dimensions ensure compatibility with construction needs. Standard sizes range from 1 inch to 10 inches in width, with wall thicknesses varying between 0.065 inches to 0.500 inches. An industry report by the American Institute of Steel Construction (AISC) highlights that choosing the right dimensions can affect load capacity by up to 30%.

Consider the specific application of the square tube steel. For structural projects, larger tubes may be necessary to support heavier loads. However, larger sizes can lead to added weight and costs. A balance is essential. Engineers often provide guidelines, but these can vary. Misjudgments in sizing could result in safety hazards or inefficiencies.

Testing your requirements with precision tools is critical. A common mistake is overlooking the need for tolerances. According to a report by the Steel Construction Institute, improper sizing contributes to 15% of project delays. Factoring in environmental conditions is also vital, as thermal expansion could affect fit. Engage with professionals for tailored advice and avoid common pitfalls associated with wrong measurements.

When sourcing square tube steel for projects, several best practices can guide you. Quality and specifications are critical. According to the Metal Service Center Institute, about 70% of structural failures in construction relate to material quality. Opt for suppliers who provide certifications proving adherence to industry standards, such as ASTM specifications.

Tips: Always ask for a detailed material report. This document should outline the chemical composition and mechanical properties.

Cost is another factor that can't be overlooked. In 2022, the average price of square tube steel jumped by 20% due to global supply chain disruptions. Set your budget and align it with your project scope. Cheap doesn't always mean cost-effective. Evaluate long-term performance rather than sole initial expenses.

Tips: Don't compromise on thickness and weldability. These attributes can significantly affect the longevity of your project.

Consider the finish as well. Some projects require galvanized or coated steel to prevent corrosion. Neglecting this element can lead to premature failure, especially in exposed environments. Remember, the right choice today can impact safety and durability tomorrow.