-

Phone

-

E-mail

-

Whatsapp

Choosing the right Carbon Steel Pipe for your projects is crucial. The right choice can impact the outcome significantly. Factors like strength, durability, and cost all come into play.

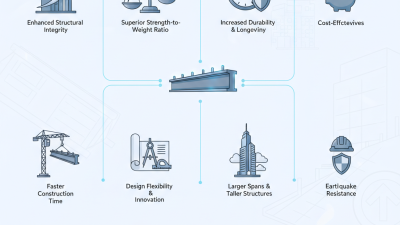

Carbon Steel Pipe offers various advantages. It's known for its strength and affordability. However, there can be pitfalls. Selecting the wrong grade or size may lead to failures. Understanding specifications is essential.

When considering Carbon Steel Pipe, think about your project's specific needs. Are you working in high-pressure settings? Or perhaps in corrosive environments? These details matter. Take the time to research and even reflect on past experiences. Making an informed decision will pay off in the long run.

When selecting carbon steel pipe for various applications, understanding grades and specifications is crucial. Carbon steel pipes are categorized mainly into three grades: low carbon, medium carbon, and high carbon. Low carbon steel typically contains less than 0.3% carbon. It is often chosen for projects requiring good ductility and weldability. Medium carbon steel, containing 0.3% to 0.6% carbon, offers a balance of strength and toughness. This makes it suitable for structural applications. High carbon steel, with over 0.6% carbon, is less ductile and harder but suitable for specific uses like high-strength components.

Industry reports highlight that the demand for carbon steel pipe is projected to grow steadily, driven by construction and energy sectors. According to a 2023 market analysis, the global carbon steel pipe market is expected to reach USD 55.7 billion by 2028. This demand underscores the importance of selecting the right grades and specifications to meet project requirements. Despite the abundant options, choosing incorrectly can lead to failures, impacting safety and project timelines.

Many factors, such as pressure ratings and temperature resistance, need consideration. For example, API 5L grades are designed for pipelines and oil and gas applications. However, specifying the wrong grade can compromise integrity, leading to costly repairs. Projects should focus on rigorous testing and validation to ensure selectivity aligns with industry standards.

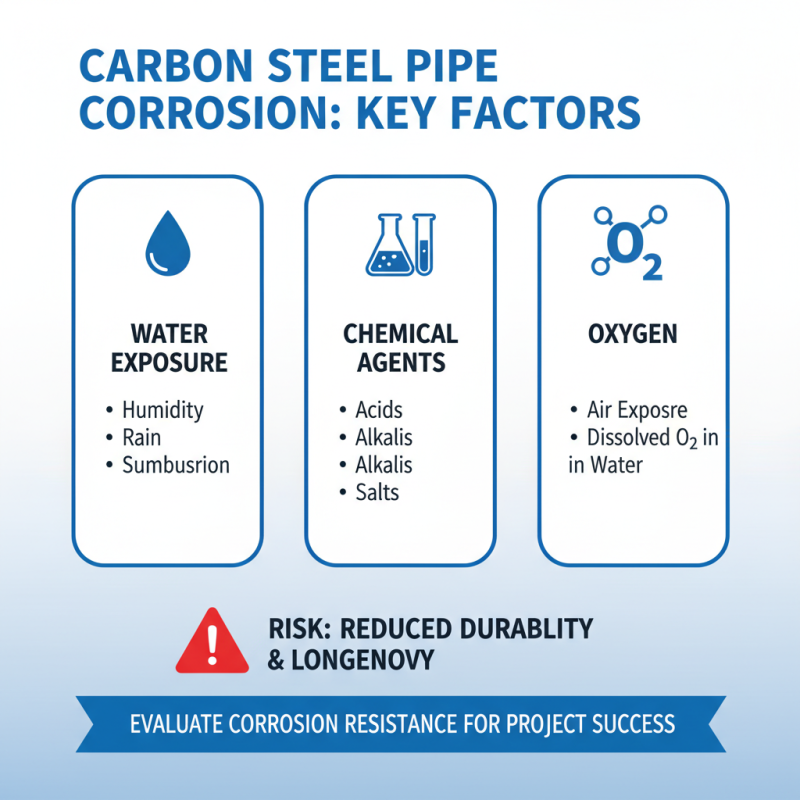

When selecting carbon steel pipes, evaluating their corrosion resistance is crucial. Corrosion can significantly affect the durability and longevity of pipes. These pipes are often exposed to various environmental factors. Water, chemicals, and even oxygen can accelerate corrosion. Understanding these risks is essential for project success.

A key aspect of assessing corrosion resistance lies in the material composition. Some carbon steel pipes have protective coatings. These coatings can offer additional layers of defense. However, not all coatings are created equal. Some may wear off quickly, exposing the pipe underneath. Regular inspections can help identify early signs of corrosion.

Another factor to consider is the intended use of the pipes. For example, pipelines in coastal areas face tougher conditions than those in dry environments. The salt and moisture in coastal regions can lead to faster corrosion rates. Understanding the specific environment is necessary for making informed choices. Remember, choosing the wrong pipe can lead to costly repairs down the line. Evaluating corrosion resistance is not just a step; it’s a fundamental part of the decision-making process.

When selecting the right dimensions for carbon steel pipe, start with project requirements. Think about flow rates and pressure. These factors easily influence pipe size. Measure the intended application carefully. If you overlook this, your project can face delays.

Consider industry standards, but remember that they may not fit your specific needs. Sometimes, custom sizes may be necessary. A common mistake is overestimating or underestimating pipe thickness. How heavy is the material? This detail affects durability and installation.

Always double-check your calculations. Consult with professionals if you are unsure. A small error can lead to significant issues down the line. Be open to adjusting your plans based on feedback. Learning from past experiences can improve future projects.

| Dimension | Measurement (inches) | Wall Thickness (inches) | Weight (lbs/ft) | Applications |

|---|---|---|---|---|

| 1/2 | 0.84 | 0.109 | 1.24 | Hydraulic systems |

| 3/4 | 1.05 | 0.113 | 1.51 | Water supply |

| 1 | 1.32 | 0.133 | 1.90 | Gas pipelines |

| 1 1/4 | 1.66 | 0.140 | 2.27 | Structural supports |

| 1 1/2 | 1.90 | 0.145 | 2.80 | Industrial applications |

When selecting carbon steel pipes, understanding the pressure ratings is crucial. These ratings determine how well the pipes can handle stress and fluid dynamics. A pipe with a higher pressure rating is generally more durable. However, it also tends to be more expensive and heavier. You'll want to balance strength and cost effectively.

It is essential to assess your project's specific needs before making a choice. Consider the fluids being transported. Their temperature and pressure levels can greatly influence the pipe's performance. For instance, a gas application might require a different rating than a liquid. Sometimes, misjudgments in selecting the right rating can lead to unexpected issues, such as leaks or pipe failure.

Also, think about installation and maintenance. A pipe rated for higher pressure may require more robust support systems. It might take longer to install as well. Reflect on your team’s expertise in handling such materials. A hasty decision based solely on pressure ratings can lead to operational inefficiencies.

When selecting carbon steel pipe, considering cost and long-term value is crucial. Studies indicate that carbon steel pipes usually range in price from $0.60 to $4 per foot, depending on the specifications and market conditions. This variability can affect project budgets significantly. A lower upfront cost may attract immediate interest, but it could lead to higher maintenance costs over the long term.

One important aspect is corrosion resistance. Carbon steel pipes may require protective coatings or linings depending on their application. These additional costs can add up, undermining initial savings. Also, project timelines can stretch if issues arise from using inferior materials. A decision based solely on price can come back to haunt projects. According to industry reports, properties like yield strength and weldability impact overall project efficiency.

Long-term value shouldn't be overlooked. While carbon steel might seem cheaper today, it could face higher replacement rates. A study from the American Institute of Steel Construction suggests that investing in higher-quality materials can save up to 30% over the material lifecycle. You may think you're saving money, but the choice could cost you more. Understanding the real cost of ownership is vital for making informed decisions.