-

Phone

-

E-mail

-

Whatsapp

Nickel Alloy Steel Pipes play a crucial role in various industries. These pipes are known for their strength and resistance to corrosion. According to James Anderson, a renowned expert in metallurgy, "Nickel Alloy Steel Pipes offer exceptional durability for demanding applications." His insights highlight the importance of these pipes in sectors such as oil and gas, chemical processing, and power generation.

In the construction of pipelines, Nickel Alloy Steel Pipes stand out due to their ability to withstand extreme temperatures and pressures. Their unique composition provides enhanced mechanical properties. Yet, the manufacturing process can be challenging. Ensuring consistency in quality is vital but not always achieved. Flaws in production can lead to failures in harsh environments.

The versatility of Nickel Alloy Steel Pipes makes them ideal for various applications. However, choosing the right material for specific conditions requires careful consideration. Industries must reflect on the implications of their choices and the long-term performance of these pipes.

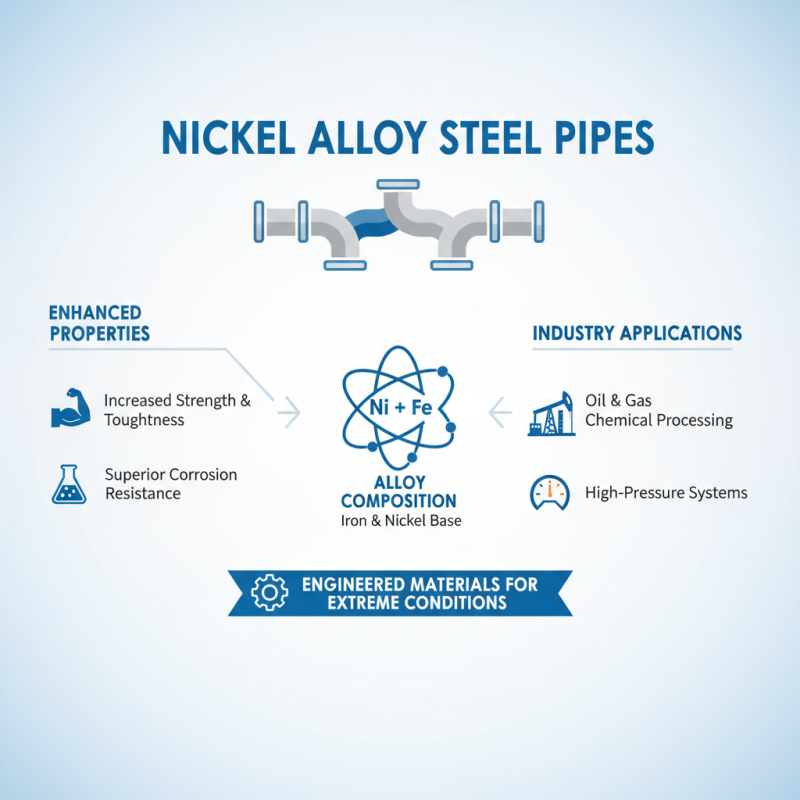

Nickel alloy steel pipes are engineered materials, combining iron and nickel to enhance strength and resistance to corrosion. These pipes find extensive use in industries where traditional steel fails to perform under aggressive conditions. The addition of nickel improves the structural integrity and toughness, making these pipes ideal for high-pressure systems.

In various industries, nickel alloy steel pipes are crucial. For instance, the oil and gas sector frequently uses them due to their ability to withstand harsh environments. According to the American Society for Testing and Materials (ASTM), nickel alloy steels offer high resistance to oxidation and performance in extreme temperatures. Data from industry reports suggest that the global nickel alloy pipe market is projected to grow by 5% annually through 2025, indicating a rising demand.

However, challenges remain. The cost of nickel alloy steel pipes is higher compared to other materials. This can lead to concerns over budget constraints. Additionally, issues related to weldability and processing can complicate production. Manufacturers need to meticulously address these concerns to avoid suboptimal outcomes. Overall, while nickel alloy steel pipes are a high-performance option, it is important to weigh their benefits against potential drawbacks.

Nickel alloy steel pipes are notable for their high strength and resistance to corrosion. These pipes typically contain nickel, chromium, and iron. The presence of nickel enhances their durability. For example, a common composition might include 6% nickel and 18% chromium. This combination provides excellent mechanical properties and thermal stability. According to industry reports, the global demand for nickel alloy steel pipes is expected to grow by 5% annually.

The characteristics of nickel alloy steel are impressive. They maintain integrity under extreme conditions. For instance, their resistance to oxidation and stress corrosion cracking makes them suitable for various applications. Industries such as aerospace and petrochemical rely heavily on this material. A study noted that these alloys can perform well in temperatures up to 1000°F. However, they can be challenging to weld, requiring specific techniques.

One concern with nickel alloy steel is the rising cost of nickel. Market fluctuations can impact production costs. This warrants attention, as price changes may affect project budgets. Furthermore, the complex alloying process can sometimes lead to inconsistencies. It's vital for manufacturers to ensure quality control throughout production. Despite these issues, the advantages of nickel alloy steel pipes often outweigh the drawbacks.

Nickel alloy steel pipes are produced using various manufacturing processes. These pipes are known for their strength and resistance to corrosion. The manufacturing begins with the selection of raw materials. Nickel, chromium, and other metals are combined. This creates an alloy that is more resilient.

Hot working is a common technique. In this process, the metal is heated and shaped. It allows for better mechanical properties. Cold working, on the other hand, helps in enhancing the strength. This method involves shaping metal at room temperature. The combination of these processes ensures durability and reliability.

Welding is crucial in pipe manufacturing. This process connects different pipe sections. However, achieving high-quality welds can be challenging. Improper techniques may lead to weak joints. Non-destructive testing is often needed to ensure integrity. It's important to consider these factors carefully. Each step requires attention and precision.

Nickel alloy steel pipe offers unique properties that make it suitable for various industries. One notable application is in the oil and gas sector. These pipes withstand high pressures and corrosive environments, ensuring safe transport of fluids. They are often seen in offshore drilling rigs, where durability is essential.

In the aerospace industry, nickel alloy steel pipes play a crucial role. They are used in fuel systems and hydraulic lines. The combination of strength and lightweight characteristics aids in improving efficiency. Manufacturers often face challenges in sourcing raw materials that can meet stringent safety standards.

Moreover, the chemical processing industry benefits significantly from these pipes. They resist extreme temperatures and provide reliable performance. However, imperfections can arise during manufacturing, leading to failures under stress. Continuous monitoring and testing are vital to avoid such issues.

Nickel alloy steel pipes are known for their strong resistance to corrosion and high temperatures. They shine in extreme environments. Industries like oil and gas rely heavily on these materials. According to a report by the Global Market Insights, the nickel alloy steel pipe market is projected to grow significantly, reaching a value of $5 billion by 2026. This growth reflects the rising demand across various sectors, particularly in chemical processing and petrochemical applications.

The advantages of using nickel alloy steel pipes are notable. They offer excellent mechanical properties. For instance, they can withstand pitting and stress corrosion cracking, especially in chlorinated environments. The toughness of nickel alloys allows them to function at low temperatures and high pressure. However, they can be expensive. This cost can deter smaller companies.

Moreover, not all nickel alloy steels are created equal. Some might not perform well under certain conditions. There is variability in the alloy compositions. Understanding these differences is crucial for engineers and purchasers. Failure to choose the right type can lead to significant operational risks. Relying solely on cost-effectiveness without considering long-term durability can be misleading. It’s essential to evaluate the entire lifecycle of these materials for better project outcomes.