-

Phone

-

E-mail

-

Whatsapp

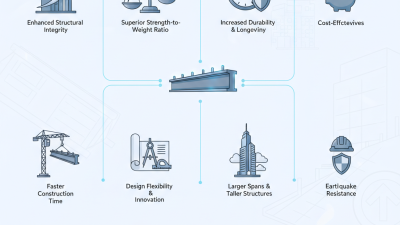

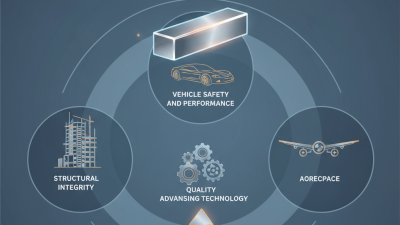

In today's construction landscape, effective use of Structural Steel is paramount for project efficiency. According to a recent report by the World Steel Association, using high-strength structural steel can reduce overall project costs by up to 30%. This significant saving highlights the importance of strategic planning and execution in construction projects.

John S. Anderson, a leading expert in Structural Steel applications, emphasizes, "The right choice of materials can make or break a project." His insights remind us that overlooking the nuances of structural steel can lead to inefficiencies. For instance, inadequate understanding of load capacities may result in structural failures or project delays.

Moreover, the integration of advanced technologies in steel fabrication can enhance accuracy and reduce waste. However, many contractors still rely on outdated practices, undermining potential gains. Reflecting on these challenges, construction teams must continuously adapt to maximize the benefits of Structural Steel while addressing inherent shortcomings in their processes. Recognizing and confronting these issues is essential for achieving successful outcomes in modern construction.

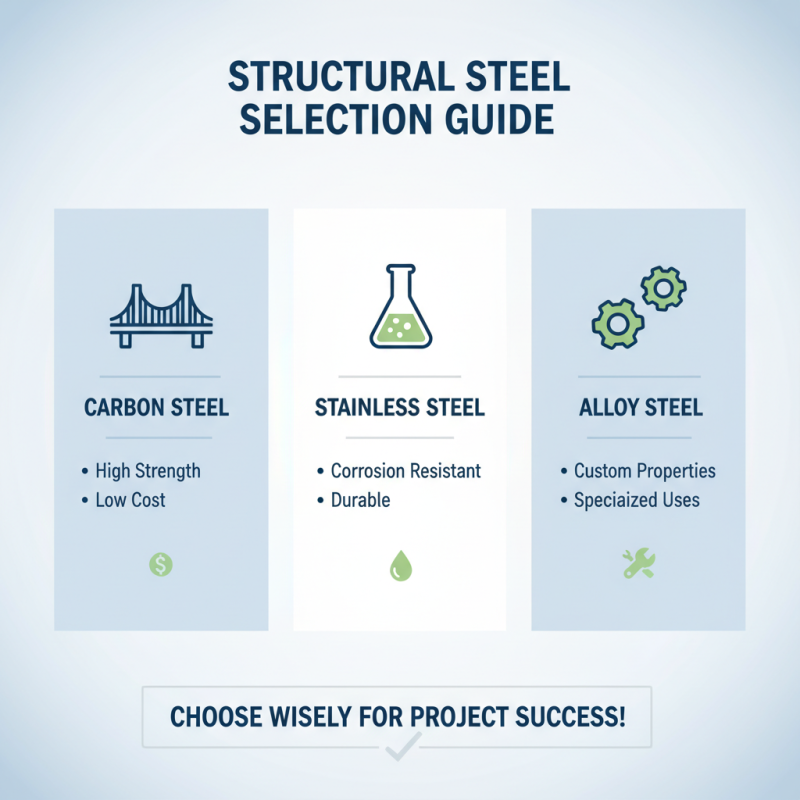

Choosing the right structural steel for your project can be challenging. Different types of steel offer distinct properties, affecting strength, cost, and weight. For instance, carbon steel is known for its tensile strength and low cost, while stainless steel offers corrosion resistance. Each option has its own niche, and the right choice depends on your specific needs.

Consider the environment where the structure will be used. If your project is in a coastal area, corrosion-resistant steel is a must. If the site faces extreme loads, you might need high-strength steel. Sometimes, the availability of materials can limit your choices. It’s important to communicate with suppliers. This way, you can avoid delays and unexpected costs.

Reflect on your project’s timeline and budget, too. While high-quality steel may lead to longer-lasting structures, it could strain your budget. Lower-grade steel options may save money initially but could increase long-term maintenance costs. Balancing quality and cost requires careful planning and foresight. It’s a complex decision that deserves thoughtful consideration.

When engaging in efficient steel construction, having the right tools and equipment is crucial. Essential tools like welders, cranes, and metal fabricators facilitate smooth operations. Each piece plays a vital role in speeding up the process. For example, a mobile crane allows for the quick lifting of heavy steel beams. Speed is essential, but safety should never be compromised.

Tips for better efficiency include planning the layout of your workspace carefully. A clutter-free site enhances productivity. Regular maintenance of tools prevents unexpected downtime. Ensure workers are well-trained on equipment to minimize errors. Often, teams overlook the importance of teamwork. Good communication can significantly reduce delays. It is about working smarter together, not just harder.

Lastly, reflect on the construction schedule. Are timelines realistic? Rushed work can lead to mistakes and setbacks. Investing time upfront can save you from costly errors later. In the realm of steel construction, efficiency comes from being prepared, staying organized, and continuously improving. With the right mindset, the construction process becomes smoother and more effective.

Preparing and fabricating steel components for construction requires precision and efficiency. According to a report by the American Institute of Steel Construction, nearly 20% of project delays result from poor steel fabrication practices. This highlights the importance of meticulous planning and execution. Properly streamlined processes can save both time and costs, leading to smoother project execution.

One key aspect is the use of advanced fabrication techniques. Automated machinery can enhance accuracy while reducing human error. However, many firms still rely on outdated methods, risking quality and schedule. The report indicates that modernizing fabrication processes can decrease material waste by up to 30%. This presents substantial savings over time.

Additionally, steel components should be manufactured with careful attention to specifications. Regular audits can catch discrepancies before they escalate. Surprisingly, many projects overlook this step, leading to costly corrections. Ensuring consistent quality is crucial. Inefficient practices not only inflate budgets but can undermine the overall integrity of the project. By fostering a culture of quality, firms can see significant improvements.

| Best Practice | Description | Benefits | Implementation Tips |

|---|---|---|---|

| Precision Fabrication | Use advanced techniques for accurate steel component creation. | Reduces waste and ensures better fit on-site. | Invest in high-quality CNC machines and skilled labor. |

| Effective Planning | Develop a detailed project timeline and resource allocation plan. | Minimizes delays and optimizes resource usage. | Use project management software to track progress. |

| Quality Control | Implement comprehensive quality checks throughout the fabrication process. | Ensures structural integrity and compliance with standards. | Regularly train staff on quality inspection methods. |

| Safety Practices | Establish clear safety protocols and training for all workers. | Reduces accidents and project downtime. | Conduct regular safety drills and workshops. |

| Collaboration and Communication | Foster open lines of communication among team members. | Encourages teamwork and faster problem resolution. | Utilize collaboration tools like Slack or Microsoft Teams. |

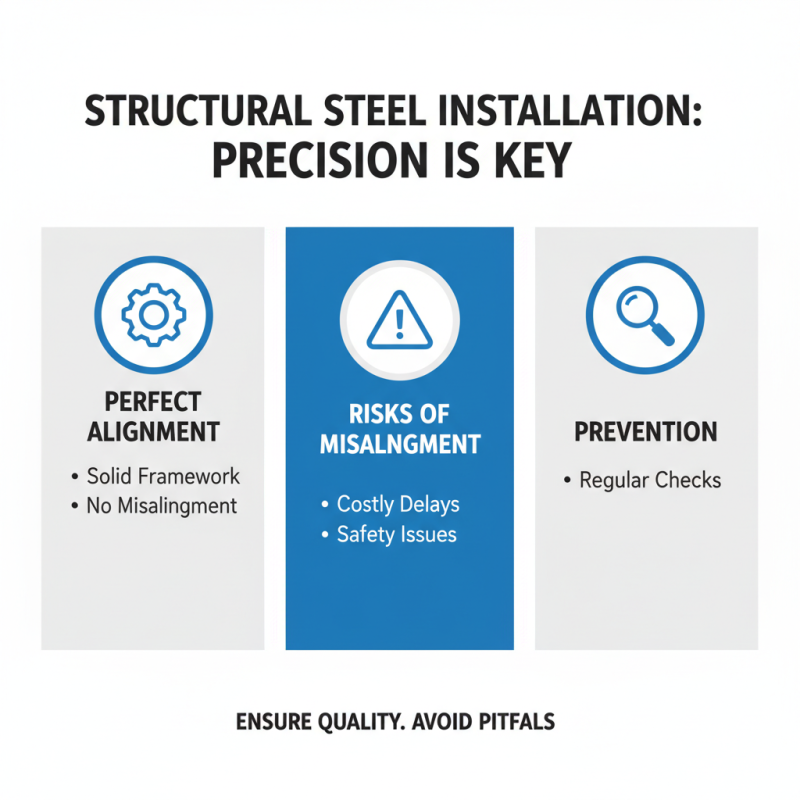

When it comes to installing structural steel, precision is key. Each piece must align perfectly for a solid framework. Misalignment can lead to costly delays and safety issues. Regular checks during installation can help prevent these pitfalls.

Tips for effective installation include using the right tools. A quality level ensures that steel beams are straight. Consider using temporary bracing to support the steel as you work. It’s essential to communicate clearly with your team. Everyone must understand their role to boost efficiency.

Carefully planning each phase is crucial. Overlooking minor details may lead to major setbacks. Sometimes, the simplest tasks are the ones that need the most attention. Don't let underestimating small components jeopardize your project. Reflect on past projects to avoid repeating mistakes. Timely adjustments can save both time and resources.

In steel construction projects, safety is paramount. According to the Occupational Safety and Health Administration (OSHA), falls are the leading cause of fatalities in the construction industry. Steel structures often require workers to operate at great heights. Adherence to safety regulations can reduce accident rates significantly. Regular safety audits and training programs are essential for reinforcing safe practices on site.

Tip: Ensure that all workers use appropriate personal protective equipment (PPE). This includes helmets, harnesses, and steel-toed boots. Proper training on how to use PPE is equally important.

In addition, understanding regulations like the American National Standards Institute (ANSI) guidelines is crucial. Compliance with these standards ensures that projects meet safety and quality benchmarks. However, many still overlook these important details. For instance, improper inspections of steel components can lead to structural failures, jeopardizing both safety and project timelines.

Tip: Conduct thorough inspections before installation. Create a checklist to ensure all components meet required specifications. This can prevent costly mistakes down the line.