-

Phone

-

E-mail

-

Whatsapp

Selecting the right stainless steel pipe for your project is a crucial decision that can significantly impact the efficiency and longevity of your application. According to a report by the Global Stainless Steel Pipe Market Analysis, the demand for stainless steel pipes is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2023 to 2028, driven by their corrosion resistance and versatility in various industries including construction, manufacturing, and oil and gas. With such a thriving market, understanding how to select the appropriate type of stainless steel pipe is imperative.

Industry expert Dr. Emily Chen, a leading materials engineer, emphasizes the importance of this selection process: “Choosing the right stainless steel pipe is not just about specifications; it’s about understanding the unique demands of your project and the environmental conditions it will face.” This highlights that while standardization is essential, each project may pose distinct challenges that require tailored solutions. In the following sections, we will explore the top 10 tips for effectively navigating the complex landscape of stainless steel pipe options, ensuring that you make informed decisions that meet your project’s specific requirements.

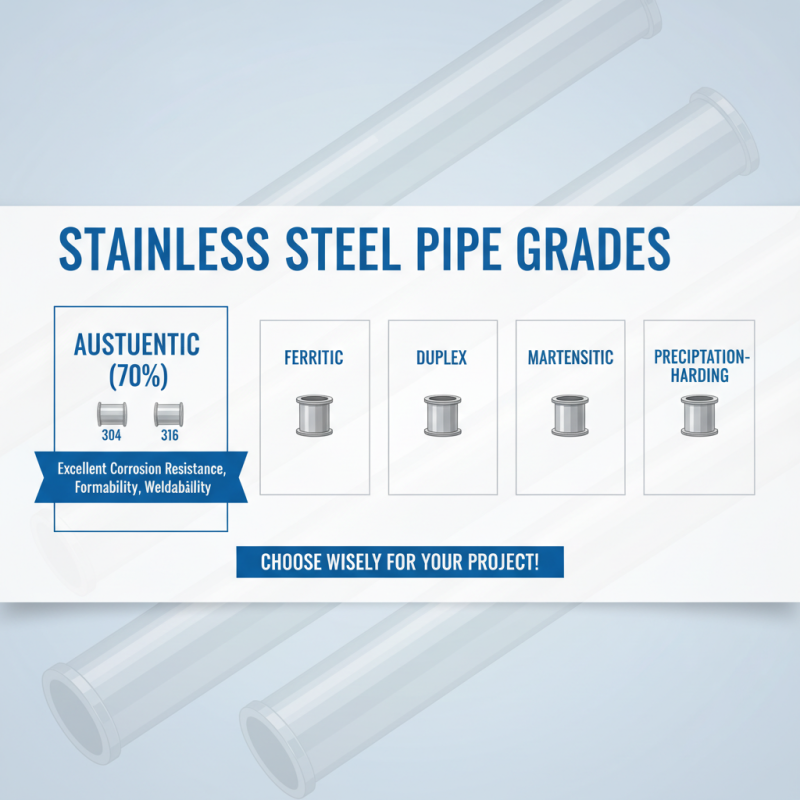

When selecting stainless steel pipes for your project, understanding the different grades is crucial. Stainless steels are categorized primarily into five different grades: austenitic, ferritic, duplex, martensitic, and precipitation-hardening. Among these, austenitic grades, such as 304 and 316, account for approximately 70% of all stainless steel production. These grades are favored for their excellent corrosion resistance, formability, and weldability, making them ideal for a variety of applications, from food processing to chemical handling.

When making a selection, consider the environment in which the pipe will be used. For instance, 316 grade stainless steel is often preferred in marine applications due to its superior resistance to chloride-induced corrosion compared to 304 grade. A report by the International Stainless Steel Forum notes that while 304 is adequate for many industrial applications, the additional molybdenum found in 316 offers greater durability in harsher conditions.

Tip: Always assess the specific requirements of your project before choosing a grade. Working with stainless steel pipes in food or medical applications may require compliance with certain standards, emphasizing the importance of choosing the appropriate grade. Additionally, consider factors such as pressure ratings and temperature tolerance, as these can significantly affect the performance and longevity of the stainless steel pipes in your project.

When selecting the right stainless steel pipe for your project, evaluating the pipe size and dimensions is a critical aspect that can significantly impact performance and cost. The diameter of the pipe is one of the foremost considerations, as it dictates the flow rate and pressure drop within the system. Industry standards, such as those published by the American Society for Testing and Materials (ASTM), provide guidelines on appropriate pipe sizes for various applications, ensuring optimal fluid transport and system efficiency. For instance, a report by the International Stainless Steel Forum (ISSF) indicates that a well-chosen pipe diameter can help reduce energy consumption by as much as 20%.

Additionally, the thickness of the pipe wall, often specified in terms of schedules (such as Schedule 40 or Schedule 80), plays a crucial role in the durability and strength of the installation. Thicker walls lend increased resistance to pressure and corrosion, which is vital in industries involving high-temperature processes or abrasive materials. According to a survey conducted by the Stainless Steel Pipe Manufacturers Association, approximately 30% of premature pipe failures can be attributed to improper thickness selections, underscoring the importance of adhering to specifications based on the intended use.

Adaptation to local environmental conditions and codes is also paramount, as regulations may dictate minimum standards or materials suited for specific applications, further influencing the choice of dimensions for optimal project outcomes.

When selecting the right stainless steel pipe for your project, one of the most critical factors to consider is corrosion resistance. Stainless steel is renowned for its durability and ability to withstand harsh environments, but not all grades offer the same level of protection against corrosion. Depending on the specific application—be it industrial, medical, or residential—evaluating the environmental conditions the pipe will face is paramount. For example, exposure to chemicals, moisture, or varying temperatures can significantly influence the performance of stainless steel over time.

To ensure optimal performance, it is essential to match the stainless steel grade to its intended use. Higher chromium and nickel content typically enhances corrosion resistance, making alloys such as 316 stainless steel ideal for marine environments or areas prone to chlorides. On the other hand, if the application involves less aggressive conditions, a lower-grade stainless steel may suffice. Furthermore, it’s crucial to consider the surface finish of the pipe, as a smoother finish can reduce the likelihood of corrosion by minimizing the accumulation of contaminants. By thoroughly assessing these aspects, you can select the most suitable stainless steel pipe that will not only meet project specifications but also ensure long-term reliability and performance.

| Tip Number | Tip Description | Corrosion Resistance Level | Common Applications |

|---|---|---|---|

| 1 | Choose the right grade of stainless steel | High | Chemical processing |

| 2 | Evaluate the environment of use | Medium | Food and beverage |

| 3 | Consider pipe thickness | Varying | Piping systems |

| 4 | Look for certifications and standards | High | Construction |

| 5 | Assess weldability requirements | Medium | Structural applications |

| 6 | Check for passivation treatment | High | Marine environments |

| 7 | Review the cost and budget | Varying | General use |

| 8 | Consider maintenance requirements | Medium | Industrial applications |

| 9 | Seek expert advice if needed | N/A | All applications |

| 10 | Test for environmental stress corrosion | High | Aerospace, oil and gas |

When selecting the right stainless steel pipe for your project, understanding pipe thickness and weight standards is critical to ensuring suitability for specific applications. The thickness of a stainless steel pipe is typically measured in schedule numbers, which reflect the wall thickness. For instance, Schedule 40 pipes feature a standard wall thickness that is suitable for many structural applications, while Schedule 80 pipes, with a thicker wall, are often utilized in high-pressure environments. According to the American National Standards Institute (ANSI) and the American Society for Testing and Materials (ASTM), adhering to these standards ensures reliability and safety in various industrial applications.

Weight standards also play a vital role in determining the appropriate stainless steel pipe for your project. The weight of the pipe not only impacts transportation and installation costs but also influences the overall structural integrity of the installation. For example, the weight of a Schedule 40 stainless steel pipe can range significantly depending on its diameter; a 1-inch diameter pipe weighs approximately 2.0 lbs per foot, while a larger 4-inch pipe can weigh around 6.6 lbs per foot. Understanding these specifics allows engineers and project managers to make informed decisions based on the structural load requirements and material handling capabilities of their projects, as outlined in industry reports such as the "Stainless Steel Pipe Industry Overview" published by the International Stainless Steel Forum (ISSF).

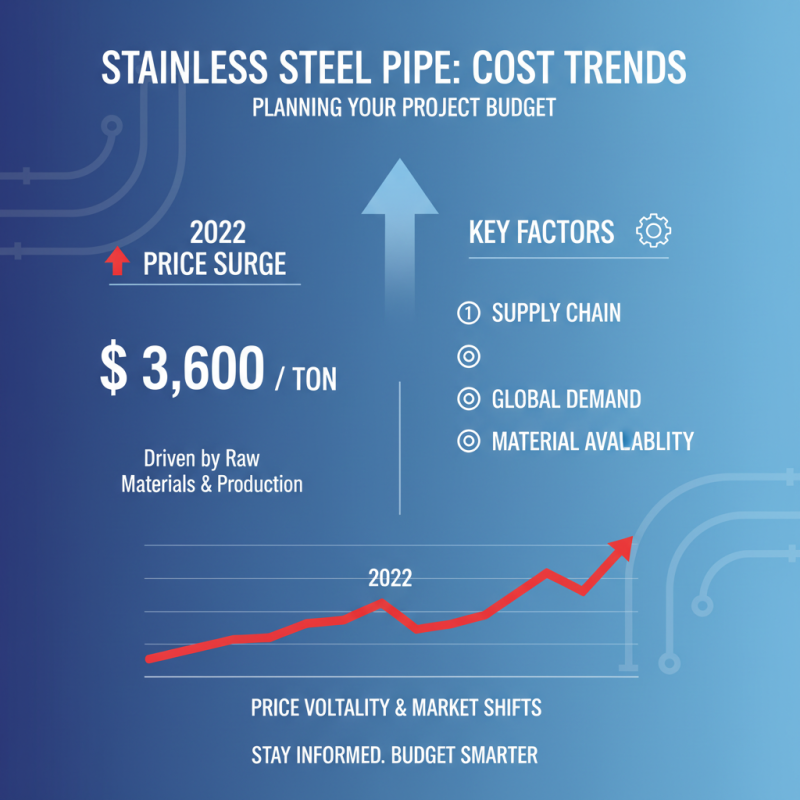

When selecting the right stainless steel pipe for a project, one crucial factor to consider is the cost and availability of materials. According to the Steel Market Update, the price of stainless steel has shown significant fluctuations due to supply chain challenges and global demand shifts. For example, in 2022, the average price for stainless steel piping surged to around $3,600 per ton, a stark increase from previous years, primarily driven by increased raw material costs and production limitations. Understanding these price trends can help you plan your budget more effectively.

Moreover, availability can significantly impact project timelines. The American Iron and Steel Institute emphasizes that the stainless steel supply chain has faced disruptions, particularly during global crises such as the COVID-19 pandemic. Current data suggests that lead times for stainless steel pipes can vary from a few weeks to several months based on the type of alloy and size required. Therefore, it is essential to assess current stock levels and procure materials well in advance. Researching regional suppliers and understanding local market conditions can help ensure a smoother procurement process, thereby preventing project delays while also optimizing costs.