-

Phone

-

E-mail

-

Whatsapp

The marine industry heavily relies on the quality of materials used in shipbuilding and offshore structures. Marine steel plays a crucial role in ensuring durability and safety. According to a recent report by the International Maritime Organization, over 90% of global trade is transported by sea. This increasing demand places significant pressure on shipbuilders to select the right materials.

Marine steel must withstand harsh conditions such as corrosion, high pressure, and extreme temperatures. The selection of steel type impacts not only safety but also operational efficiency. In fact, a study by SSAB reveals that more resistant materials can lead to reduced maintenance costs by up to 20%. However, not all marine steel types are created equal. Some may underperform or fail to meet project specifications.

Choosing the appropriate marine steel requires careful consideration and knowledge of industry standards. While advancements in technology offer newer options, older steel types still have their place in shipbuilding. The industry must reflect on its choices and balance tradition with innovation to meet future challenges in maritime construction.

In the world of shipbuilding and offshore structures, selecting the right marine steel is crucial. Various types of marine steel exist, each serving specific purposes. High strength low alloy (HSLA) steels are popular for their excellent weldability and strength. These are ideal for hull construction, where durability is essential. Another type, carbon-manganese steel, offers good strength and toughness, making it suitable for larger vessels.

When choosing marine steel, consider the environment. Corrosive conditions can affect steel longevity. Stainless steel provides better corrosion resistance but at a higher cost. This is important for offshore rigs exposed to harsh elements.

**Tips:** Always assess the specific requirements of your project. Think about the types of loads the structure will endure. Test samples before full-scale production. Not all materials perform as expected in real-world scenarios. Reflecting on past projects can help you avoid mistakes. Be prepared to adapt your choices based on changing needs or failures in the initial approach.

| Steel Type | Chemical Composition | Mechanical Properties | Applications |

|---|---|---|---|

| AH36 | C: max 0.20, Mn: 0.90-1.60 | Yield Strength: 355 MPa | Ship hulls, marine structures |

| EH32 | C: max 0.20, Mn: 0.90-1.50 | Yield Strength: 315 MPa | Offshore platforms, bulk carriers |

| D32 | C: max 0.20, Si: max 0.50 | Yield Strength: 315 MPa | Tankers, container ships |

| S355G10 | C: max 0.20, Mn: 1.2-1.6 | Yield Strength: 355 MPa | Offshore wind structures, jackets |

| Grade LR A | C: max 0.20, Mn: 0.90-1.40 | Yield Strength: 240 MPa | Bulk carriers, general cargo ships |

| NV D36 | C: max 0.20, P: max 0.025 | Yield Strength: 355 MPa | Supply vessels, naval applications |

| A32 | C: max 0.20, Si: max 0.50 | Yield Strength: 320 MPa | Fishing vessels, tugs |

| Grade AS/NZS 3678 | C: max 0.25, Mn: 0.75-1.50 | Yield Strength: 300 MPa | Structural applications, shipbuilding |

| A131 | C: max 0.20, Mn: 0.90-1.50 | Yield Strength: 235 MPa | Marine structures, cargo tankers |

| S420G1 | C: max 0.18, Zn: for corrosion resistance | Yield Strength: 420 MPa | Platforms, marine construction |

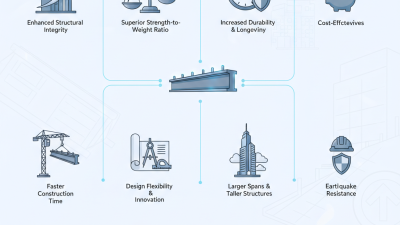

Marine steels are essential for shipbuilding and offshore structures. Their unique properties ensure resilience in harsh marine environments. Typically, these steels have high tensile strength and excellent corrosion resistance. This adaptability extends the lifespan of vessels and platforms.

The most effective marine steels often contain specific alloying elements. For instance, a study by the International Maritime Organization suggests that steel grades like AH36 and DH36 retain ductility while achieving significant strength. This is critical, as stresses from waves and currents can weaken materials. Observations indicate that vessels constructed with appropriate marine steels demonstrate 30% less wear than those using standard grades.

However, not all marine steels perform perfectly. Some may exhibit fatigue over time, leading to structural concerns. The lack of uniformity in marine conditions can affect performance. Engineers must find a balance between strength and weight. Surveillance of material integrity is vital for ensuring safety. Frequent inspections highlight potential weaknesses. It’s not only about choosing the right steel but also maintaining it. Understanding these factors is essential for sustained operational efficiency.

When it comes to shipbuilding, choosing the right marine steel is crucial. Various grades of marine steel are tailored to withstand harsh marine environments. Corrosion resistance, tensile strength, and weldability are key factors in this selection process. Common grades include AH36 and DH36. These are popular for hull construction and offshore structures.

Marine steel grades are often categorized by specifications. For instance, ASTM A131 sets standards for shipbuilding steel. This includes mechanical properties and chemical composition. Additionally, EN 10025 covers structural steel. Understanding variations in these specifications helps ensure safety and durability.

While many steel types exist, not all are suited for every project. There may be challenges with availability or cost. Sometimes, less utilized grades may be overlooked. Relying solely on popular choices can lead to missed opportunities. Exploration of alternatives is often necessary. This path may reveal unique benefits and features.

In marine construction, corrosion resistance is crucial. Ships and offshore structures face harsh environments. Saltwater, humidity, and temperature changes can create severe corrosion issues. Choosing the right steel type can significantly mitigate these risks.

Marine grades of steel often include additives. These enhance durability and resistance to rust. Commonly, alloys like nickel and chromium are mixed to achieve specific properties. Regular inspections are also vital. Even the best steel can suffer from unexpected wear. Ignoring minor signs of corrosion can lead to bigger problems.

Tips: Use paint coatings for added protection. They form a barrier and can prolong steel life. Consider cathodic protection systems too. These help prevent corrosion through electrochemical means. Routine maintenance is non-negotiable. A small effort can save huge costs in the long run.

The future of marine steel development is crucial for sustainable shipping practices. Advances in materials can reduce environmental impact. Innovations include stronger, lighter steel. These materials enhance fuel efficiency. There is a focus on recycling and reusability as well.

Tips: Always consider the life cycle of materials. Conduct thorough research on new alloys. Assess how they affect overall performance.

New trends involve duplex stainless steels and high-strength low-alloy steels. These options promise durability in harsh marine environments. However, manufacturers must address potential costs. Balancing performance and budget is vital. Collaboration between industry and research institutions is key to overcoming hurdles.

Tips: Engage with experts during the material selection process. Test materials under real conditions. Learn from past failures to avoid repeat issues.