Carbon alloy pipe: top - grade combo

specification

|

Product Name |

Carbon steel alloy pipe |

|

Standard |

ASTM,JIS,DIN,GB,AISI,DIN,EN |

|

Material |

Q195、Q235、Q345、20#、45#、60#、65#、16Mn、30CrMo、35CrMo、ASTM A106、ASTM A53 |

|

Outer diameter range |

ASTM A106: The outer diameter range is usually from 1/8 inch (about 3.2mm) to 48 inches (about 1219mm). ASTM A53: The outer diameter range is usually from 1/2 inch (about 12.7mm) to 24 inches (about 610mm). GB Standard: GB/T 8162: The outer diameter ranges from 10mm to 1000mm, and the specific size can be customized according to requirements. GB/T 8163: The outer diameter ranges usually from 15mm to 1000mm. EN Standard: EN 10216: The outer diameter ranges from 10mm to 1000mm, and the specific size can be customized according to requirements. |

|

Thickness range |

ASTM Standard: ASTM A106: Wall thickness typically ranges from 0.5mm to 50mm, depending on the outer diameter of the pipe. ASTM A53: Wall thickness generally ranges from 0.5mm to 25mm. GB Standard: GB/T 8162: Wall thickness typically ranges from 2mm to 30mm, depending on the outer diameter. GB/T 8163: Wall thickness usually ranges from 3mm to 20mm. EN Standard: EN 10216: Wall thickness typically ranges from 2mm to 30mm, depending on the outer diameter. |

|

Length range |

Customized length according to customer's special requirements. |

|

Error |

±1% |

|

Certification |

ISO 9001 ,CE,API |

|

Surface treatment |

Hot-dip galvanizing、Cold galvanizing、Spraying、Phosphate treatment、Polishing、Oxidation treatment、Coating |

|

Country of origin |

China |

|

Main Applications |

1.Oil and gas industry Purpose: Pipeline systems used for transporting oil, natural gas and related products. Features: Pipes that require high pressure resistance and corrosion resistance are usually made of seamless or welded carbon steel alloy pipes. |

|

2.Chemical Industry Application: Used in chemical transportation, storage and reaction equipment. Features: Pipes that need to be resistant to corrosion and high temperatures often use alloy elements to enhance their performance. |

|

|

3.Architecture and Structural Engineering Application: Used for support and framework of building structures, bridges, towers, etc. Features: High strength and good welding performance are required, and low alloy high strength steel pipes are commonly used. |

|

|

4.Machinery manufacturing Use: Used in manufacturing machinery parts, equipment and tools. Features: Requires good processing performance and strength, commonly used medium carbon steel and alloy steel pipes. |

|

|

5.Power Industry Application: Used in cooling systems of power equipment, power transmission lines, etc. Features: Pipes that require high temperature resistance and corrosion resistance, commonly used alloy pipes. |

|

|

6.Automotive industry Application: Used in automobile chassis, exhaust system and other parts. Features: Lightweight and high strength are required, and high-strength carbon steel alloy pipes are commonly used. |

|

|

7.Water treatment and water supply system Application: Used in urban water supply, sewage treatment and other pipeline systems. Features: Pipes that require corrosion resistance and pressure resistance, commonly used coated or galvanized pipes. |

|

|

Package |

Simple packaging, reinforced packaging, wooden frame, metal frame, pallet, wrapping |

|

Payment Term |

TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

|

After-sales service |

1. Quality assurance period 2. Return and exchange policy 3. Delivery and acceptance assistance 4. Customer feedback collection |

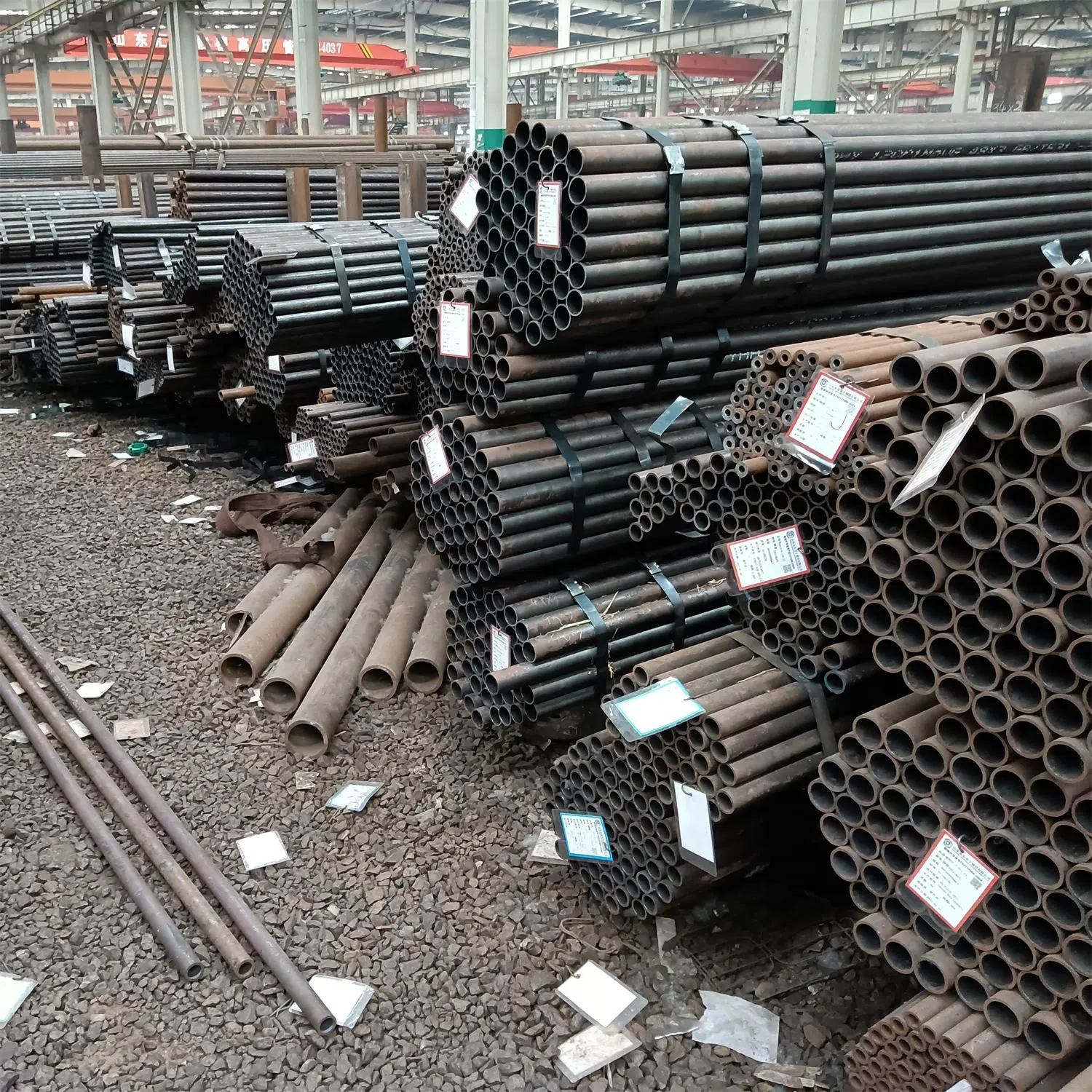

Product Display

Production process

1. Raw material preparation

Select alloy composition: Select the appropriate carbon steel alloy material according to product requirements, usually in the form of billet or ingot.

Chemical composition analysis: Conduct chemical composition analysis on raw materials to ensure they meet standard requirements.

2. Heating

Heating furnace: The steel billet is placed in a heating furnace and heated to a certain temperature (usually between 1100°C and 1300°C) for the subsequent forming process.

3. Molding

Hot rolled or cold rolled:

Hot rolling: The heated billet is rolled through a series of rolling mills to gradually form the required outer diameter and wall thickness.

Cold rolling: The formed tube is further rolled at room temperature to improve its precision and surface finish.

4. Pipeline Forming

Seamless pipe production: The heated steel billet is perforated into a tube billet by a perforation process, and then the diameter is expanded and sized.

Welded pipe production: Steel plates or strips are rolled into a tube shape and the edges are connected by welding processes (such as arc welding, laser welding, etc.) to form a pipe.

5. Heat Treatment

Normalizing or annealing: Heat treatment of the formed pipe to improve its mechanical properties and organizational structure and eliminate internal stress.

6. Surface treatment

Cleaning: Remove oxide scale, oil stains and other impurities on the pipe surface.

Coating or galvanizing: Surface treatment such as hot-dip galvanizing, spraying, phosphating, etc. as needed to improve corrosion resistance.

7. Testing

Dimensional inspection: Measure the outer diameter, wall thickness, length, etc. of the pipe to ensure compliance with standards.

Non-destructive testing: Use ultrasonic, X-ray and other non-destructive testing methods to check for internal defects in pipelines.

Chemical composition analysis: reconfirm that the chemical composition of the finished product meets the requirements.

8. Packaging and Shipping

Packaging: Qualified carbon steel alloy pipes are packaged to prevent damage during transportation.

Shipping: Arrange shipment according to customer requirements.