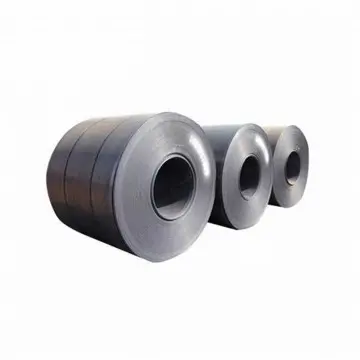

Carbon Steel

DIN 17100 ST37/ST12/ST14/ST52 Carbon Steel Coil

ST37 steel coils are known for their excellent weldability and formability, making them ideal for structural applications. With a low carbon content, ST37 offers good tensile strength and is commonly used in the construction of buildings, bridges, and other infrastructure projects.

ST12 steel coils, on the other hand, are characterized by their exceptional ductility and malleability. This makes them perfect for deep drawing applications, such as automotive parts and household appliances. The smooth surface finish of ST12 steel coils also allows for easy painting and coating, enhancing their aesthetic appeal.

For applications requiring higher strength, our ST14 steel coils are an excellent choice. With improved mechanical properties, ST14 is suitable for manufacturing components that demand higher load-bearing capabilities. This steel grade is often utilized in the production of machinery, equipment, and structural components.

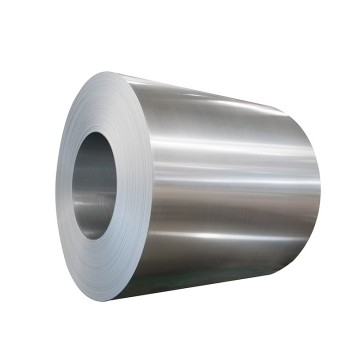

SPCC/SPCD/SPCE Cold Rolled Steel Coil

SPCC, SPCD, and SPCE are designations that refer to different grades of cold-rolled steel, each tailored to meet specific requirements. SPCC, or Cold Rolled Carbon Steel, is known for its excellent formability and surface finish, making it ideal for applications such as automotive parts, appliances, and furniture. SPCD, a higher-grade variant, offers improved mechanical properties, making it suitable for more demanding applications where strength and resilience are paramount. Finally, SPCE provides the highest level of quality among the three, featuring superior elongation and tensile strength, perfect for intricate designs and high-stress environments.

EN10025-2 S235/S275/S355 Carbon Steel Coil

S235, S275, and S355 are structural steel grades that are widely recognized for their excellent mechanical properties and weldability. S235 is the most basic grade, offering a minimum yield strength of 235 MPa, making it ideal for general construction applications. S275, with a yield strength of 275 MPa, provides enhanced performance for more demanding structural requirements. For projects that require superior strength, S355 boasts a yield strength of 355 MPa, making it the preferred choice for heavy-duty applications.

JIS G3101 SS400/SS490/SS540 Cold Rolled Steel Coil

SS400, SS490, and SS540 are structural steel grades that are widely recognized for their excellent mechanical properties. SS400 is known for its good weldability and formability, making it an ideal choice for general structural applications. With a minimum yield strength of 235 MPa, it is suitable for a variety of construction projects, from buildings to bridges.

SS490 takes it a step further, offering a higher yield strength of 325 MPa. This makes it an excellent option for applications that require enhanced load-bearing capabilities. Its superior toughness and ductility ensure that it can withstand harsh conditions, making it a reliable choice for heavy-duty structures.

All three grades are available in coil form, allowing for easy handling and processing. They can be cut, shaped, and welded to meet specific project requirements, making them incredibly versatile for fabricators and builders alike.

DC01/DC02/DC03/DC04 Cold Rolled Steel Coil

The DC series of steel coils is designed with precision and reliability in mind. Each grade—DC01, DC02, DC03, and DC04—offers unique properties tailored to specific applications. DC01 is known for its excellent formability and weldability, making it ideal for automotive components and structural applications. DC02, with its enhanced mechanical properties, is perfect for manufacturing parts that require a balance of strength and ductility. DC03 is designed for applications that demand superior surface quality and is often used in the production of household appliances and furniture. Finally, DC04 offers the highest level of formability, making it suitable for intricate designs and complex shapes.

API Spec 5L Pipeline Steel Coil

The API Spec 5L Pipeline Steel Coil is manufactured in accordance, ensuring that it meets the highest industry standards for quality and performance. This steel coil is available in various grades, including X42, X52, X60, and X70, allowing for tailored solutions that cater to specific project requirements. Its superior mechanical properties ensure that it can withstand extreme pressures and harsh environmental conditions, making it suitable for both onshore and offshore applications.

Standard 1018 cold - rolled steel coil

1018 steel is a low-carbon steel alloy, known for its excellent weldability, machinability, and formability. With a carbon content of approximately 0.18%, this steel offers a perfect balance between strength and ductility, making it an ideal choice for applications that require both toughness and ease of fabrication. The 1018 Steel Coil is particularly favored in the automotive, aerospace, and machinery sectors, where precision and reliability are paramount.

One of the standout features of the 1018 Steel Coil is its ability to be easily shaped and formed into complex geometries without compromising its structural integrity. This makes it an excellent option for producing components such as shafts, gears, and brackets. Additionally, its superior surface finish allows for enhanced aesthetic appeal and improved performance in applications where friction and wear are concerns.

AISI/SAE 4140 Carbon Steel Bar

AISI/SAE 4140 is a chromium-molybdenum alloy steel that boasts a unique combination of properties, making it ideal for applications that require both durability and reliability. With a carbon content of approximately 0.40%, this steel exhibits excellent hardenability, allowing it to achieve high hardness levels through heat treatment. The addition of chromium and molybdenum enhances its strength and resistance to deformation, ensuring that it can withstand the rigors of demanding environments.

The round shape of AISI/SAE 4140 steel makes it particularly versatile, allowing for easy machining and fabrication into various components. Whether you need shafts, gears, or structural parts, this steel can be easily processed to meet your specific requirements. Its excellent weldability further expands its usability, making it suitable for a variety of manufacturing techniques.

AISI/SAE 4130 Carbon Steel Bar

AISI/SAE 4130 round steel is characterized by its unique chemical composition, which includes approximately 0.28-0.33% carbon, 0.8-1.1% manganese, 0.15-0.25% molybdenum, and 0.4-0.6% chromium. This combination of elements not only enhances the steel's mechanical properties but also contributes to its ability to withstand high temperatures and pressures. The round shape of this steel makes it particularly suitable for manufacturing components such as shafts, axles, and tubing, where uniform strength and reliability are paramount.

One of the standout features of AISI/SAE 4130 round steel is its adaptability to various heat treatment processes. Whether it’s normalized, quenched, or tempered, this alloy can be tailored to meet specific performance requirements, ensuring that it meets the rigorous standards of any project. Additionally, its excellent machinability allows for easy fabrication, making it a preferred choice for engineers and manufacturers alike.

AISI/SAE 1045 C45 Carbon Steel Bar

AISI/SAE 1045, also known as C45 in Europe, is characterized by its carbon content of approximately 0.45%, which strikes an optimal balance between strength and ductility. This unique composition allows for excellent machinability, making it suitable for producing intricate components with precision. The round steel bars are available in various diameters, catering to diverse project requirements, from automotive parts to machinery components.

One of the standout features of AISI/SAE 1045 C45 round steel is its ability to be heat-treated, enhancing its hardness and wear resistance. This adaptability makes it an excellent choice for applications that demand durability and longevity, such as shafts, gears, and axles. Additionally, its weldability ensures that it can be easily integrated into various fabrication processes, providing flexibility in design and manufacturing.

AISI/SAE 1018 Carbon Steel Bar

AISI/SAE 1018 round steel is characterized by its carbon content, which typically ranges from 0.15% to 0.20%. This low carbon content contributes to its enhanced machinability and formability, allowing it to be easily shaped and cut to meet specific project requirements. The round shape of this steel makes it particularly suitable for applications such as shafts, axles, and pins, where uniformity and strength are paramount.

In addition to its mechanical properties, AISI/SAE 1018 round steel is also known for its excellent surface finish, which can be further enhanced through processes such as cold drawing or machining. This not only improves the aesthetic appeal of the final product but also contributes to its overall performance in demanding environments.

A572/S355JR bar with good tensile strength

The A572/S355JR round steel is manufactured using advanced metallurgical processes, ensuring consistent quality and performance. With its superior yield strength and tensile strength, this steel grade is capable of withstanding significant loads and stresses, making it perfect for use in bridges, buildings, and various industrial structures. Its excellent weldability and formability allow for easy fabrication, enabling engineers and contractors to create complex designs with confidence.

One of the standout features of A572/S355JR round steel is its resistance to atmospheric corrosion, which enhances its longevity and reduces maintenance costs over time. This makes it an ideal choice for outdoor applications and environments where exposure to the elements is a concern. Additionally, the steel's ability to perform well at low temperatures ensures that it remains reliable even in challenging conditions.

A105 Carbon Steel Bar with Good Machinability

The A105 Round Steel is manufactured to meet ASTM A105 specifications, ensuring that it can withstand extreme temperatures and pressures. This makes it particularly suitable for use in piping systems, valves, and fittings, where reliability is crucial. Its round shape allows for easy installation and integration into existing systems, providing a seamless solution for engineers and contractors alike.

One of the standout features of A105 Round Steel is its excellent weldability, which allows for efficient fabrication and assembly. Whether you are constructing a new facility or upgrading existing infrastructure, this steel product can be easily welded to other materials, ensuring a strong and secure connection. Additionally, its corrosion resistance properties make it suitable for use in harsh environments, prolonging the lifespan of your projects.

A36/Q235/S235JR Carbon Steel Bar

The A36 steel grade is renowned for its excellent weldability, machinability, and structural integrity. It is a low-carbon steel that offers a good balance of strength and ductility, making it ideal for structural components in buildings, bridges, and other infrastructure projects. Similarly, Q235 and S235JR are widely recognized in the global market for their reliable performance and adaptability.

The smooth surface finish of the round steel not only enhances its aesthetic appeal but also facilitates easy handling and installation. Whether you are fabricating machinery, constructing frameworks, or creating custom metalwork, the A36/Q235/S235JR round steel provides the strength and durability required to get the job done right.