Durable and Reliable DX51D Z150 Galvanized Plate

specification

|

DX51D Z150 Galvanized Plate |

|

|

thickness:0.15-14mm or as required |

|

|

width:600-1200mm or as required |

|

|

length:600-12000mm or as required |

|

|

Grade:SGCC; SGCD1; SGCD2; SGCD3; SGC340SGC400; SGC440; SGC590; |

|

|

DX51D+Z; DX52D+Z; DX53D+Z; DX54D+Z; S250GD+Z; |

|

|

S280GD+Z; S320GD+Z; S350GD+Z; S550GD+Z; Q-BQB420-2009 |

|

|

zinc coating:Z30- 275g/m2 |

|

|

tolerance:+/-0.05mm |

|

|

Bundles / Coil Weight: 3-8MT/Coil or as your request |

|

|

Surface Treatment:Oiled / Chormed / Dry / According to customer requirements |

|

|

Application:Gutters ,Auto parts ,Electrical Appliances,Purling,Vending Machine,Refrigerator, |

|

|

Packing:standard export packing,or as customer demands |

|

|

payment Terms:30% T/T, L/C, Western Union |

|

|

Producing line |

5 sets of galvanized steel coils producing lines |

|

3 sets of hot rolled steel coils producing lines |

|

|

3 sets of hor rolled steel plate producing lines |

|

|

5 sets of deformed steel bar producing lines |

|

|

Equipment |

Laser cutting machine |

|

CNC hydraulic punching machine |

|

|

Bending machine |

|

|

Shearing machine |

|

|

Market |

We are one of the domestic biggest supplier and export to all over the word. |

|

Size |

Special specifications of steel products can produce. |

|

Production process strictly conforms to the international standard of DIN/ASTM/AISI /JIS/BS to ensure the quality. |

|

|

We can process or produce according to your drawings. |

|

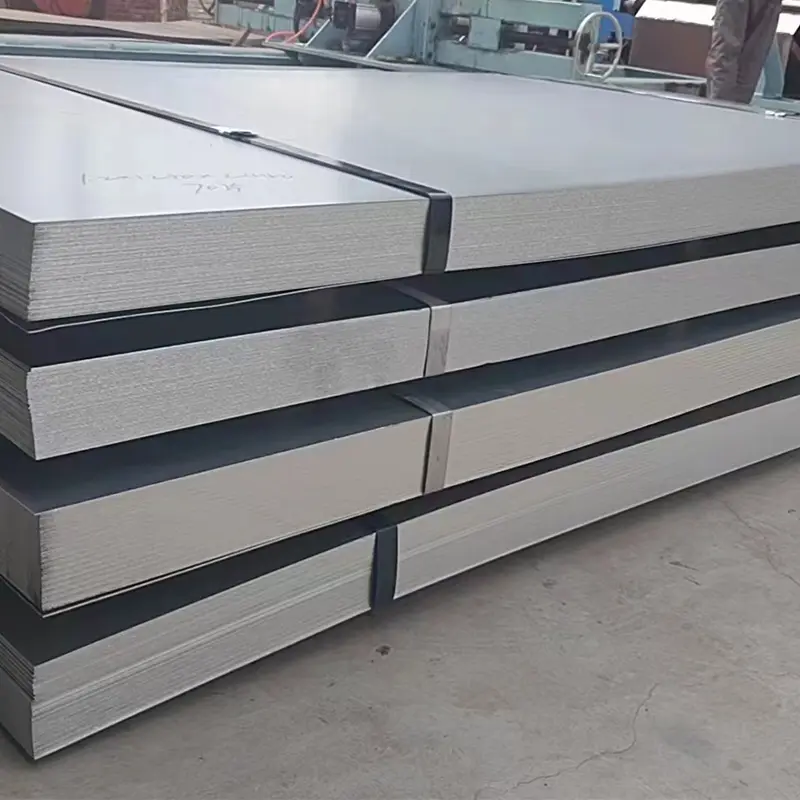

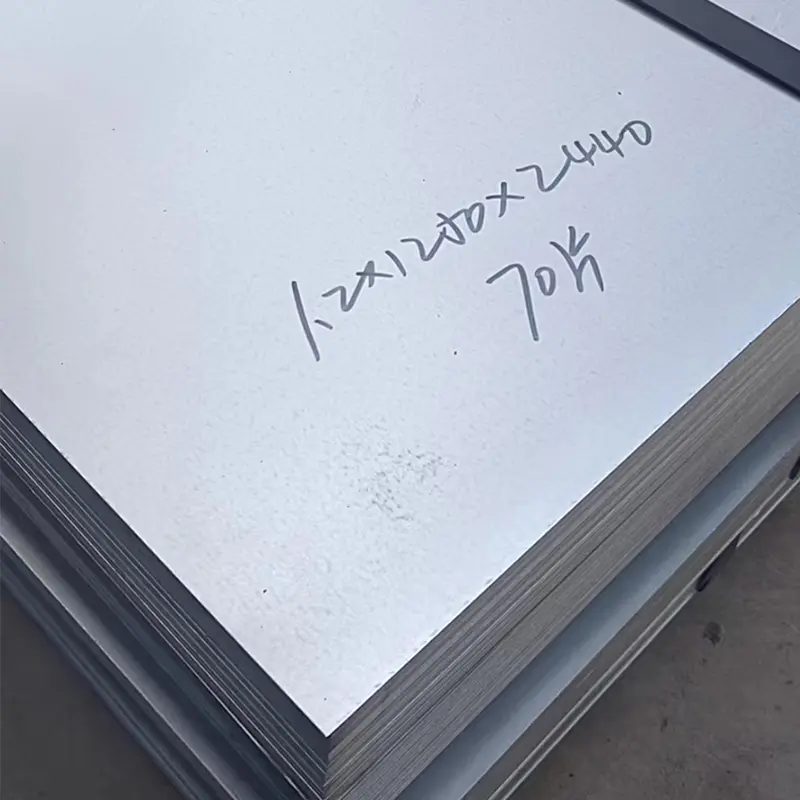

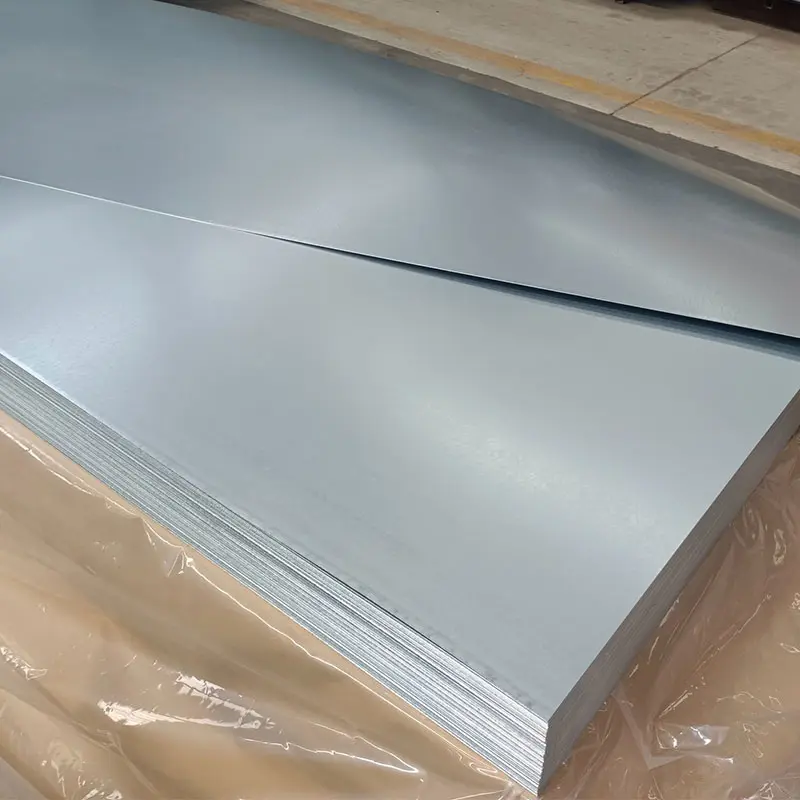

Product Display

Chemical Composition

|

Standard |

Grade |

C |

Si |

Mn |

P |

S |

Ti |

|

Forcold Forming Chinese Standard |

DX51D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

DX52D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX53D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX54D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX56D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX57D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

Mechanical Properties

|

Grade |

Yield Strength MPa≥ |

Tensile Strength MPa≥ |

Elongation A%≥ |

|

DX51D Z/ZM/AZ/AM |

240-380 |

270-500 |

22 |

|

DX52D Z/ZM/AZ/AM |

140-300 |

270-420 |

26 |

|

DX53D Z/ZM/AZ/AM |

140-260 |

270-380 |

30 |

|

DX54D Z/ZM/AZ/AM |

120-220 |

260-350 |

36 |

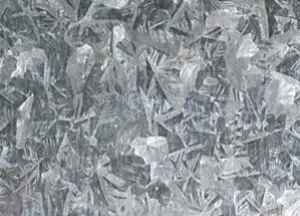

Galvanized Surface Selection

|

Zero Spangle |

Minimized Spangle |

Normal Spangle |

Large Spangle |

|

|

|

|

|

| Use of The Environment | Recommended Zinc Thickness |

| Indoor Use | Z10 or Z12 (100g/㎡or 120g/㎡) |

| Suburbs | Z20 and Painting (200g/㎡) |

| Urban or Industrial Area | Z27 (270g/㎡) or G90 (US Standard) and painted |

| Coastal Area | Thicker than Z27 (270g/㎡) or G90 (US Standard) and painted |

| Punch or Deep Drawing Application | Thicker than Z27 (270grams/㎡) or G90 (US Standard) avoid coating peeling after stamping |

| Surface Treatment Type | Code | Features |

| Chromic Acid Treatment | C | Good corrosion resistance, suitable for bare state |

| Chromic Acid Treatment+Oiling | S | Good corrosion resistance |

| Phosphoric Acid Treatment (Including Sealing Treatment) | P | Have a certain corrosion resistance, good paint performance |

| Phosphoric Acid Treatment (Including Sealing Treatment)+Oiling | Q | Has a certain corrosion resistance, good paint performance, prevent rust during transportation and storage |

| Phosphoric Acid Treatment (Excluding Sealing Treatment) | T | Have a certain corrosion resistance, good paint performance |

| Phosphoric Acid Treatment (Excluding Sealing Treatment)+Oiling | V | Has a certain corrosion resistance, good paint performance, and prevent rust |

| Oiling | O | Prevent rust during transportation and storage |

| No Treatment | M | Suitable for immediate painting |

Material Comparison

| Chinese Standard | Japan Standard | European Standard |

| DX51D Z/DC51D Z (CR) | SGCC | DX51D Z |

| DX52D Z/DC52D Z | SGCD1 | DX52D With |

| DX53D Z/DC53D Z/DX54D Z/DC54D Z | SGCD2/SGCD3 | DX53D Z/DX54D Z |

| S220/250/280/320/350/550GD Z | SGC340/400/440/490/570 | S220/250/280/320/350GD Z |

| DX51D Z/DD51D Z (HR) | SGHC | DX51D Z |