Durable Galvanized Sheet plate for Industry

specification

| Thickness | 0.13-3.0mm |

| Width | 500mm-1500mm |

| Length | As customer's request |

| Zn coating | 0.13-0.8 mm is 30-150 g/m2; 0.8-1.5 mm is 30-180 g/m2;1.5-6.0 mm is 30-275 g/m2 |

| Coil ID | 600-1500 mm,Normal width is 91 4/1000/1219/1250/1500 mm |

| Steel grade | DX51D,DX52D,DC01,DC02,SGHC |

| Surface | regular/mini/big/zero spangle,skin pass, chromated, unoiled, dry |

| Packaging | seaworthy export standard package, or according to the customers’requirement |

| Delivery time | With 15 –25 days after receipt of deposit or L/C |

| Market | North/South America, Europe, Asia,Africa,Mid East |

| Productivity | 2000 ton /month |

| Warehose Stcok | Normal Grade 10000 tons per month |

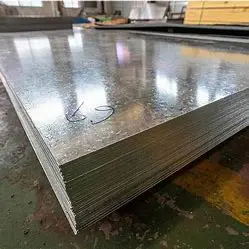

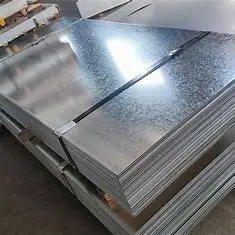

Product Display

Mechanical Properties

|

Grade |

Yield Strength MPa≥ |

Tensile Strength MPa≥ |

Elongation A%≥ |

|

DX51D Z/ZM/AZ/AM |

240-380 |

270-500 |

22 |

|

DX52D Z/ZM/AZ/AM |

140-300 |

270-420 |

26 |

|

DX53D Z/ZM/AZ/AM |

140-260 |

270-380 |

30 |

|

DX54D Z/ZM/AZ/AM |

120-220 |

260-350 |

36 |

|

S220GD Z/ZM/AM |

220 |

300 |

20 |

|

S250GD Z/ZM/AZ/AM |

250 |

330 |

19 |

|

S280GD Z/ZM/AM |

280 |

360 |

18 |

|

S300GD A/AM |

300 |

380 |

18 |

|

S320GD Z/ZM/AM |

320 |

390 |

17 |

|

S350GD Z/ZM/AZ/AM |

350 |

420 |

16 |

|

S450GD A/AM |

450 |

480 |

15 |

|

S550GD Z/ZM/AZ/AM |

550 |

550 |

- |

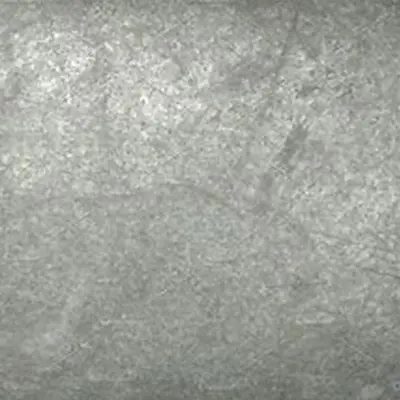

Galvanized Surface Selection

|

Zero Spangle |

Minimized Spangle |

Normal Spangle |

Large Spangle |

|

|

|

|

|

|

Use of The Environment |

Recommended Zinc Thickness |

|

Indoor Use |

Z10 or Z12 (100g/㎡or 120g/㎡) |

|

Suburbs |

Z20 and Painting (200g/㎡) |

|

Urban or Industrial Area |

Z27 (270g/㎡) or G90 (US Standard) and painted |

|

Coastal Area |

Thicker than Z27 (270g/㎡) or G90 (US Standard) and painted |

|

Punch or Deep Drawing Application |

Thicker than Z27 (270grams/㎡) or G90 (US Standard) avoid coating peeling after stamping |

|

Surface Treatment Type |

Code |

Features |

|

Chromic Acid Treatment |

C |

Good corrosion resistance, suitable for bare state |

|

Chromic Acid Treatment+Oiling |

S |

Good corrosion resistance |

|

Phosphoric Acid Treatment (Including Sealing Treatment) |

P |

Have a certain corrosion resistance, good paint performance |

|

Phosphoric Acid Treatment (Including Sealing Treatment)+Oiling |

Q |

Has a certain corrosion resistance, good paint performance, prevent rust during transportation and storage |

|

Phosphoric Acid Treatment (Excluding Sealing Treatment) |

T |

Have a certain corrosion resistance, good paint performance |

|

Phosphoric Acid Treatment (Excluding Sealing Treatment)+Oiling |

V |

Has a certain corrosion resistance, good paint performance, and prevent rust |

|

Oiling |

O |

Prevent rust during transportation and storage |

|

No Treatment |

M |

Suitable for immediate painting |

Material Comparison

|

Chinese Standard |

Japan Standard |

European Standard |

|

DX51D Z/DC51D Z (CR) |

SGCC |

DX51D Z |

|

DX52D Z/DC52D Z |

SGCD1 |

DX52D With |

|

DX53D Z/DC53D Z/DX54D Z/DC54D Z |

SGCD2/SGCD3 |

DX53D Z/DX54D Z |

|

S220/250/280/320/350/550GD Z |

SGC340/400/440/490/570 |

S220/250/280/320/350GD Z |

|

DX51D Z/DD51D Z (HR) |

SGHC |

DX51D Z |