| Product Name |

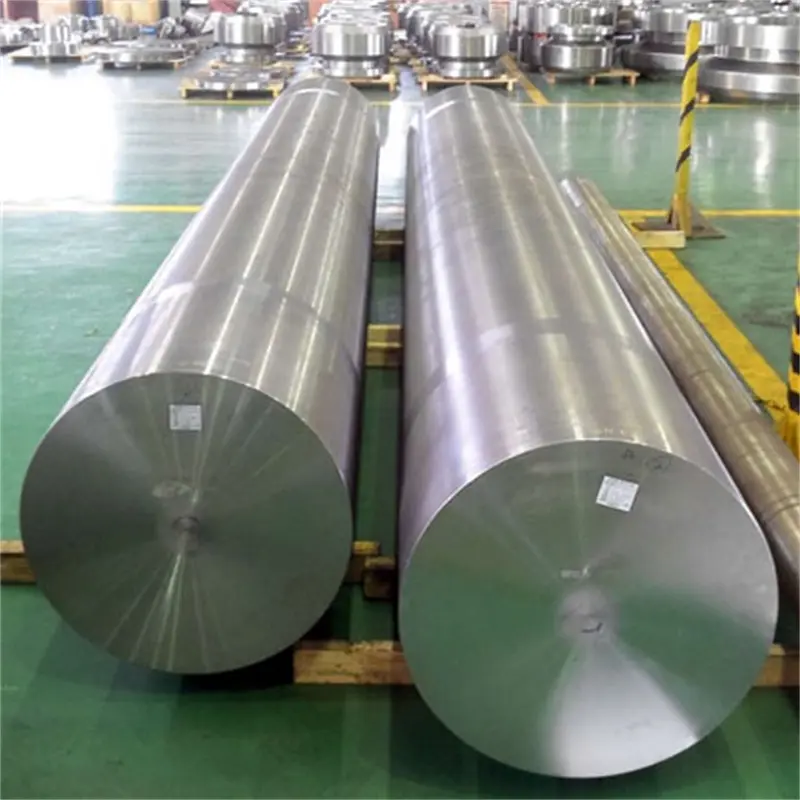

Inconel 625 Bar |

| Standard |

ASTM,JIS,DIN,GB,AISI,DIN,EN |

|

Outer Diameter

|

Round Bar

|

4mm-200mm |

| Hexagon Bar |

18mm-57mm (11/16″ to 2-3/4″) |

| Square Bar |

18mm-47mm (11/16″ to 1-3/4″) |

| Flat Steel |

1/2 "to 10", Thickness: 2mm-150mm, Can provide customized |

| Length |

1-6 meters, Length can be customized |

| Error |

±1% |

| Certification |

ISO 9001 ,CE,API |

| Surface treatment |

Black, Bright Polished, Rough Turning, Matt Surface Treatment, No.4, BA, etc. |

| Production Technology |

Hot Rolling, Cold Rolling |

| Country of origin |

China |

| Main Applications |

Mechanical engineering, automotive industry, aerospace, construction engineering, oil and gas industry, energy industry, mold manufacturing |

| Package |

Bundling, wooden box packaging, pallet packaging, plastic film packaging, anti-rust oil coating, container transportation |

| Payment Term |

TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

| After-sales service |

1. Quality assurance period

2. Return and exchange policy

3. Delivery and acceptance assistance

4. Customer feedback collection

|