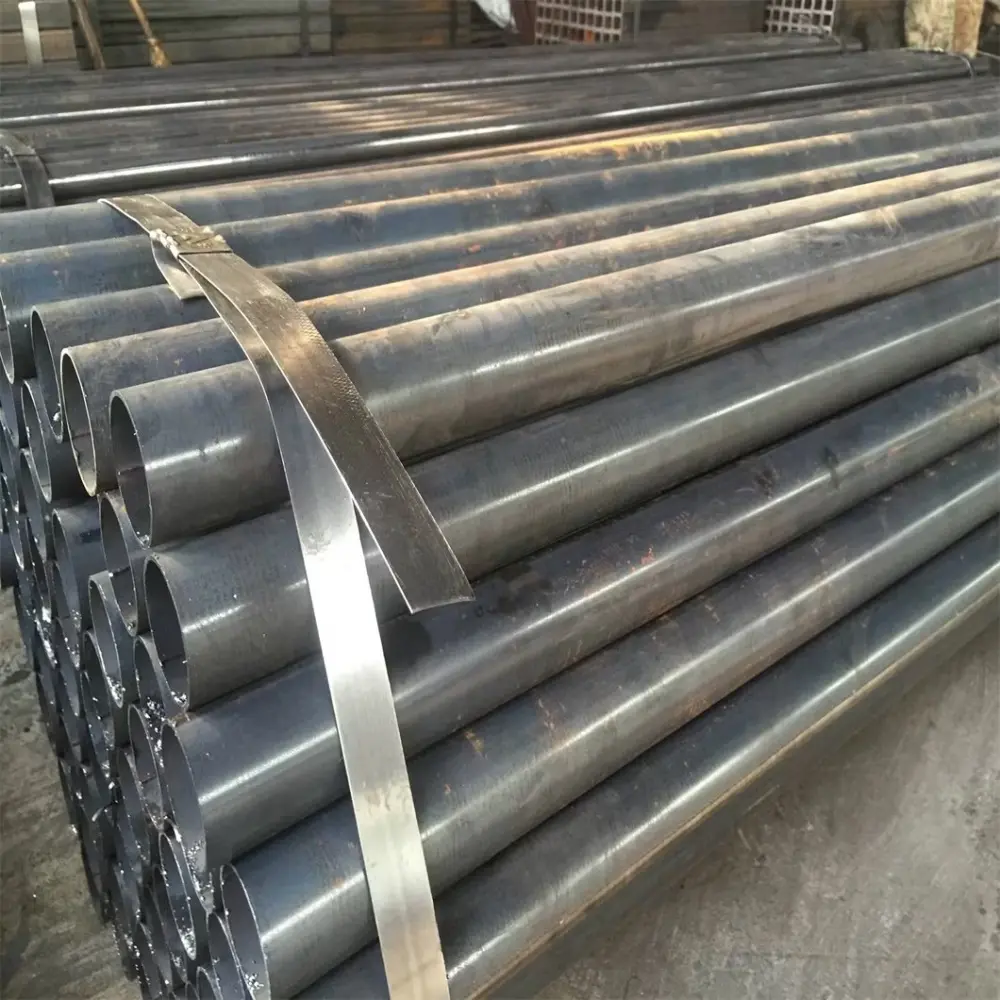

High quality Q235B high frequency welded pipe, strong and durable

specification

|

Product Name |

High frequency welded pipe |

|

Standard |

ASTM,JIS,DIN,GB,AISI,DIN,EN |

|

Material |

Q195、Q215、Q235、16Mn、20Cr、30Cr、304、316、321、6061、6063、C11000、C36000 |

|

Outer diameter range |

Small diameter high frequency welded pipe: The outer diameter is generally between 10mm and 50mm, and is commonly used for small structures and pipelines. Medium diameter high frequency welded pipe: The outer diameter is generally between 50mm and 100mm, suitable for general construction and industrial purposes. Large diameter high frequency welded pipe: The outer diameter is generally 100mm to 500mm or even larger, and is widely used in pipeline systems in the petroleum, natural gas, chemical and other industries. |

|

Thickness range |

Small diameter high frequency welded pipe: The wall thickness is generally between 1.0mm and 5.0mm, suitable for light structures and general pipelines. Medium-diameter high-frequency welded pipe: The wall thickness is generally between 3.0mm and 10.0mm, suitable for applications with higher load-bearing requirements. Large diameter high frequency welded pipe: The wall thickness is generally between 5.0mm and 20.0mm, and is widely used in heavy-duty pipelines in the petroleum, natural gas, chemical and other industries. |

|

Length range |

The longest length is 6 meters, and can be customized by customers |

|

Error |

±1% |

|

Certification |

ISO 9001 ,CE,API |

|

Surface treatment |

Hot dip galvanizing, electro galvanizing, spraying, phosphating, polishing, pickling, plastic coating |

|

Country of origin |

China |

|

Main Applications |

1.Construction industry: used in building structures, support frames, fences, stairs, etc. as load-bearing and non-load-bearing components. |

|

2.Oil and Gas Industry: Pipelines used to transport fluids such as oil and natural gas, especially under high pressure and high temperature environments. |

|

|

3.Chemical industry: used in chemical equipment, pipelines and storage tanks, suitable for conveying various chemical media. |

|

|

4.Automobile industry: used in automobile exhaust pipes, frames, suspension systems and other parts. |

|

|

5.Mechanical manufacturing: used to manufacture structural parts and accessories of various mechanical equipment. |

|

|

6.Power industry: Used for brackets and pipes for power equipment, especially in the fields of wind power and solar power generation. |

|

|

7.Home appliance industry: used for structural parts of home appliances, such as brackets and pipes of refrigerators, air conditioners, etc. |

|

|

8.Furniture industry: used to manufacture metal furniture such as tables, chairs, shelves, etc. |

|

|

Package |

Simple packaging, reinforced packaging, wooden frame, metal frame, pallet, wrapping |

|

Payment Term |

TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

|

After-sales service |

1. Quality assurance period 2. Return and exchange policy 3. Delivery and acceptance assistance 4. Customer feedback collection |

Product Display

Classification of high frequency welded pipes

Classification by material:

Carbon Steel High Frequency Welded Pipe: Mainly used for general structures and pipelines.

Alloy Steel High Frequency Welded Pipe: For high strength and high temperature resistant applications.

Stainless steel high frequency welded pipe: suitable for corrosion resistance and high temperature environment.

Aluminum Alloy High Frequency Welded Pipe: For lightweight and corrosion resistant applications.

Classification by outer diameter:

Small diameter high frequency welded pipe: The outer diameter is generally between 10mm and 50mm.

Medium diameter high frequency welded pipe: The outer diameter is generally between 50mm and 100mm.

Large diameter high frequency welded pipe: The outer diameter is generally above 100mm.

Classification by wall thickness:

Thin-wall high-frequency welded pipe: The wall thickness is generally between 1.0mm and 3.0mm.

Medium-thick wall high-frequency welded pipe: The wall thickness is generally between 3.0mm and 10.0mm.

Thick-wall high-frequency welded pipe: The wall thickness is generally above 10.0mm.

Classification by purpose:

High frequency welded pipe for structure: used for buildings, bridges and other structures.

High frequency welded pipe for fluid transportation: used for conveying fluids such as water, oil, and gas.

High frequency welded pipe for machinery: used for parts and accessories of mechanical equipment.

Classification by welding method:

Straight seam high frequency welded pipe: The welded joint is straight and suitable for most applications.

Spiral high frequency welded pipe: The welded joint is spiral-shaped and suitable for large diameter pipes.

Advantages

High production efficiency: High-frequency welding process can complete welding quickly, and its production efficiency is significantly higher than that of traditional welding methods, which is suitable for large-scale production.

Good welding quality: During high-frequency welding, the strength and sealing of the welding joint are better, the weld is uniform, and the occurrence of defects is reduced.

High material utilization rate: In the production process of high-frequency welded pipes, the material utilization rate is high, which reduces the generation of waste and reduces production costs.

Strong customizability: High-frequency welded pipes can be customized with different outer diameters, wall thicknesses and materials according to customer needs to meet diverse application requirements.

Wide adaptability: High-frequency welded pipes are suitable for a variety of materials (such as carbon steel, stainless steel, alloy steel, etc.) and can be used in different environments and conditions.

Good mechanical properties: The welded joints of high-frequency welded pipes have good mechanical properties and can withstand greater pressure and load.

Various surface treatments: High frequency welded pipes can undergo a variety of surface treatments (such as galvanizing, spraying, pickling, etc.) to improve their corrosion resistance and aesthetics.

Environmental protection: The high-frequency welding process is relatively environmentally friendly and reduces the emission of welding smoke and harmful gases.

Production process

Raw material preparation:

Choose suitable steel strip or steel plate as raw material, usually cold-rolled or hot-rolled carbon steel, stainless steel or alloy steel.

Cutting:

Cutting raw materials into required width and length for subsequent forming and welding.

Molding:

Forming machines are used to roll the cut strip or sheet into a tube. This process is usually done by passing it through several forming rollers, which gradually bend the material into the tube shape.

High frequency welding:

The formed pipe is welded by a high-frequency welding machine. The high-frequency current generates heat on the contact surface of the pipe, causing the material to melt and combine together at the contact point to form a weld.

Welding seam treatment:

After welding, the weld may be cooled and shaped to ensure the quality of the weld and the appearance of the pipe.

Annealing (optional):

Annealing treatment is performed on the welded pipe to eliminate the stress generated during the welding process and improve the mechanical properties of the pipe.

Cutting and trimming:

Cut the welded pipes into required lengths and trim the edges to ensure the pipes meet the required dimensions and appearance.

Surface treatment:

According to customer needs, the pipes are surface treated, such as hot-dip galvanizing, electro-galvanizing, spraying, pickling, etc. to improve corrosion resistance and aesthetics.

Inspection and testing:

Carry out quality inspection on finished products, including appearance inspection, dimension measurement, weld strength test, etc., to ensure that the products meet relevant standards and customer requirements.

Packaging and Shipping:

Pack qualified high frequency welded pipes and prepare to ship them to customers.