High - strength welded square tube for build

specification

|

Product Name |

welded square tube |

|

Standard |

ASTM,JIS,DIN,GB,AISI,DIN,EN |

|

Material |

Q235、Q345、304、316、201、20#、42CrMo、6061、6063 |

|

Outer diameter range |

Small diameter square tube: The outer diameter is generally between 20mm and 100mm, and is often used for light structures and small equipment. Medium diameter square tube: The outer diameter is generally between 100mm and 300mm, suitable for general construction and mechanical structures. Large diameter square tube: The outer diameter is generally between 300mm and 600mm, suitable for heavy structures and large equipment. |

|

Thickness range |

Thin-wall square tube: The wall thickness is generally between 1.0mm and 3.0mm, suitable for light structures and decorative purposes. Medium wall thickness square tube: The wall thickness is generally between 3.0mm and 6.0mm, suitable for general construction and mechanical structures. Thick-walled square tube: The wall thickness is generally between 6.0mm and 20mm, suitable for heavy structures and applications with high load-bearing requirements. |

|

Length range |

Customized length according to customer's special requirements. |

|

Error |

±1% |

|

Certification |

ISO 9001 ,CE,API |

|

Surface treatment |

Hot-dip galvanizing、Cold galvanizing、Plastic spraying、Phosphating、Polishing、Oxidation treatment |

|

Country of origin |

China |

|

Main Applications |

1.Building Structure: Welded square tubes are often used in building frames, supporting structures, fences and stairs, etc. due to their high strength and strong load-bearing capacity. |

|

2.Mechanical manufacturing: In mechanical equipment, welded square tubes can be used as racks, brackets and connectors, and are suitable for structural parts of various mechanical equipment. |

|

|

3.Transportation: Welded square tubes are widely used in structural parts and accessories of transportation vehicles such as automobiles, ships, and railways. |

|

|

4.Furniture manufacturing: Welded square tubes are often used to make modern furniture, such as tables, chairs, shelves, etc., because of their beautiful appearance and easy processing. |

|

|

5.Electricity and Communications: In the electricity and communications industries, welded square tubes are used to make electric towers, communication towers and support frames, etc. |

|

|

6.Agricultural facilities: Welded square tubes can be used for structural support of agricultural facilities such as greenhouses and farms. |

|

|

7.Sports facilities: Welded square tubes are also widely used in sports venues and fitness equipment, such as the frames and supporting structures of sports equipment. |

|

|

Package |

Simple packaging, reinforced packaging, wooden frame, metal frame, pallet, wrapping |

|

Payment Term |

TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

|

After-sales service |

1. Quality assurance period 2. Return and exchange policy 3. Delivery and acceptance assistance 4. Customer feedback collection |

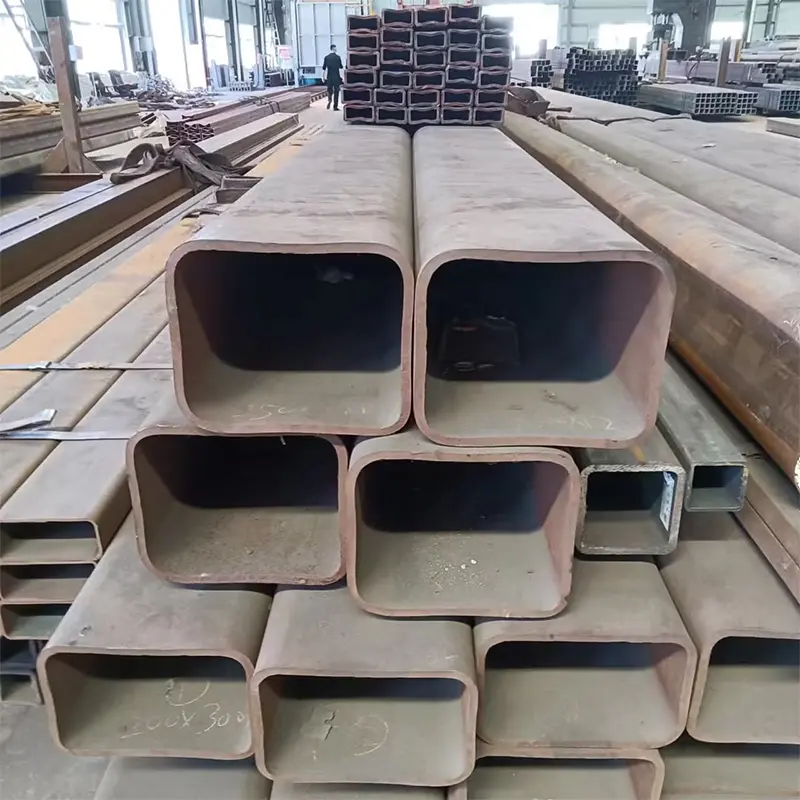

Product Display

Production process

.Raw material preparation:

Choose appropriate steel coils or steel plates as raw materials, usually hot-rolled or cold-rolled carbon steel, stainless steel, etc.

.Cutting:

Cutting steel coils or plates into appropriate widths for subsequent forming.

.Molding:

Use a forming machine to roll the cut steel strip or steel plate into the preliminary shape of the square tube.

.Welding:

Weld the edges of the formed square tube, usually using high frequency welding or submerged arc welding to ensure the strength and quality of the weld.

.Cooling:

After welding, the square tube needs to be cooled to ensure the stability and strength of the weld.

.Correction:

Correct the square tube after welding to eliminate the deformation caused by welding and ensure the straightness and dimensional accuracy of the square tube.

.Cutting:

Cut square tubes to required lengths, usually custom made to customer specifications.

.Surface treatment:

Carry out surface treatment as needed, such as hot-dip galvanizing, plastic spraying, polishing, etc. to improve the corrosion resistance and aesthetics of the square tube.

.Inspection:

Carry out quality inspection on finished products, including appearance, size, weld quality, etc., to ensure compliance with relevant standards and customer requirements.

.Packing and Delivery:

Pack qualified welded square tubes and prepare to ship to customers.