Inconel 625 alloy steel spiral welded pipe

specification

|

Product Name |

Inconel 625 alloy steel spiral welded pipe |

|

Standard |

ASTM B444、GB/T 12771、GOST 19281、BS 3076、DIN 17750、JIS G 3461 |

|

Material |

Inconel 625 |

|

Outer diameter range |

Small OD Tubing: Usually starts from 1/2 inch (about 12.7 mm). Large OD Tube: Can be up to 24 inches (about 610 mm) or larger, depending on the manufacturer’s capabilities and customer needs. |

|

Thickness range |

Thin-wall tubing: Usually starts from 0.5 mm (about 0.020 inches). Medium Wall Thickness Tube: Common wall thickness ranges from 1.0 mm (about 0.040 inches) to 5.0 mm (about 0.197 inches). Thick Wall Tube: Can be up to 10 mm (about 0.394 inches) or thicker, depending on the manufacturer’s capabilities and customer needs. |

|

Length range |

The longest length is 6 meters, and can be customized by customers |

|

Error |

±1% |

|

Certification |

ISO 9001 ,CE,API |

|

Surface treatment |

Pickling, passivation, sandblasting, electrolytic polishing, coating, heat treatment |

|

Country of origin |

China |

|

Main Applications |

1.Oil and Gas Industry: Used in offshore oil platforms, pipelines and storage tanks, able to withstand high temperatures, high pressures and corrosive environments. |

|

2.Chemical and petrochemical industries: Used in chemical reactors, heat exchangers and piping systems, especially when handling corrosive media. |

|

|

3.Aerospace: Used in the manufacture of aerospace engine components and other high temperature applications due to its stability and strength in extreme temperatures. |

|

|

4.Power Industry: Components for gas and steam turbines that can withstand high temperatures and corrosive gases. |

|

|

5.Marine Engineering: Used in marine environments, such as submarine pipelines and equipment, due to its excellent resistance to seawater corrosion. |

|

|

6.Nuclear Energy Industry: Used in nuclear reactor components due to its high temperature and corrosion resistance. |

|

|

7.Food and Pharmaceutical Industry: Used in the manufacture of equipment and pipes due to its good hygienic properties and corrosion resistance. |

|

|

Package |

Simple packaging, reinforced packaging, wooden frame, metal frame, pallet, wrapping |

|

Payment Term |

TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

|

After-sales service |

1. Quality assurance period 2. Return and exchange policy 3. Delivery and acceptance assistance 4. Customer feedback collection |

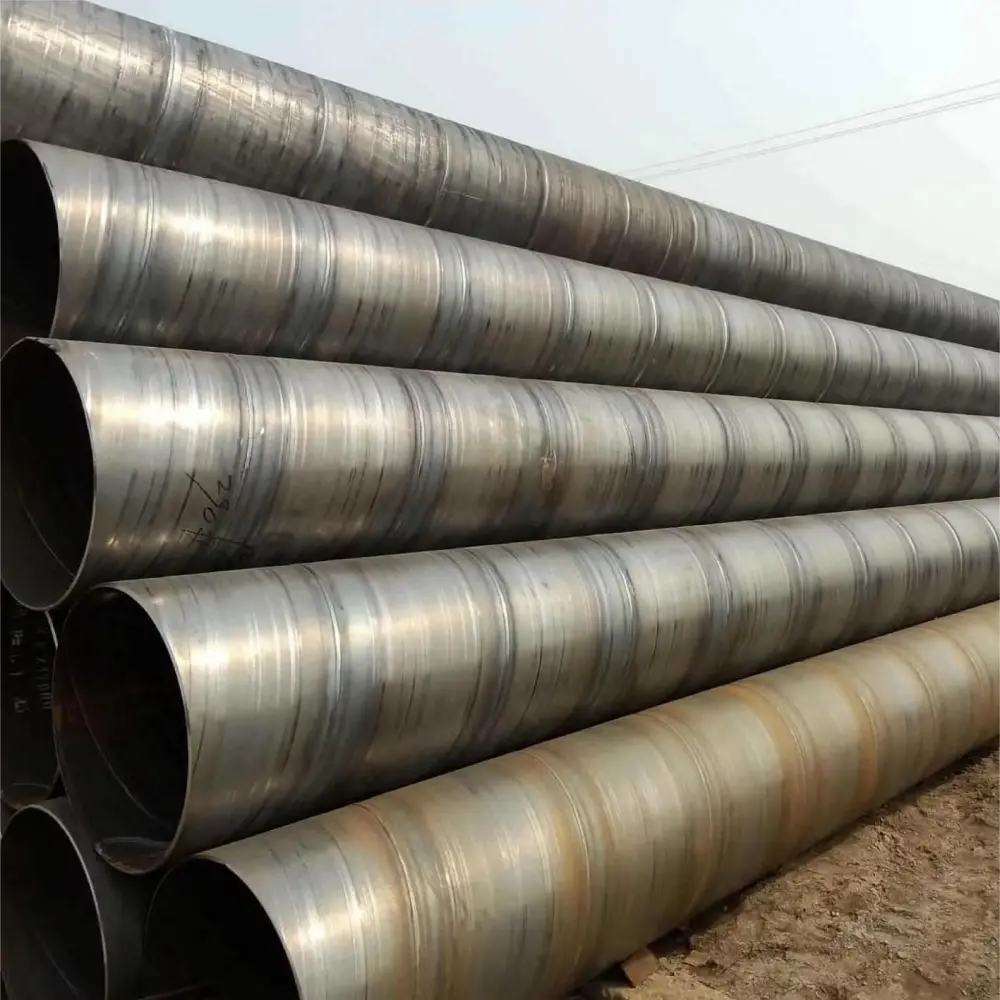

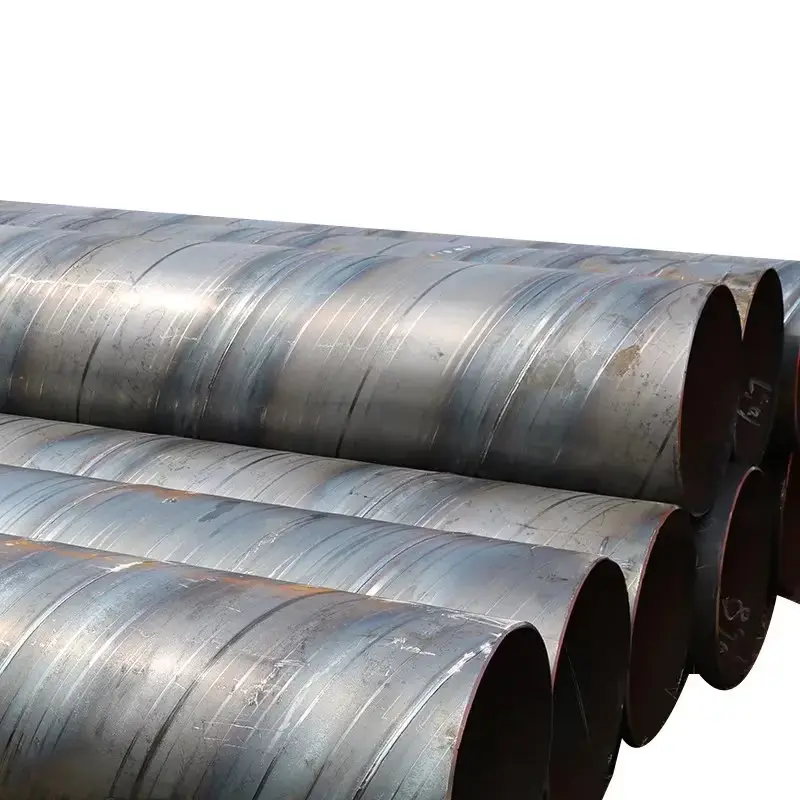

Product Display

Chemical Composition

C |

Si |

Mn |

Cr |

Ni |

S |

P |

Mo |

Fe |

Ti |

AI |

0.1 |

≤ 0.5 |

≤ 0.5 |

20.0 - 23.0 |

58.0-63.0 |

≤0.010 |

≤0.015 |

8.0-10.0 |

≤ 5.0 |

≤ 0.4 |

≤ 0.4 |

Mechanical Properties

Tensile Strength Kb (MPa) |

Yield Strength σ0.2 (MPa) |

Elongation D5 (%) |

Hardness |

≥1030 |

≥ 690 |

≥ 30 |

250 HB |

Production process

1.Raw material preparation

Choose high-quality Inconel 625 alloy material, usually available in the form of round bars or plates.

2.Heat treatment

Appropriate heat treatment of the raw materials to improve their mechanical properties and machinability. This may include processes such as annealing.

3.Molding

The raw material is processed into the preliminary shape of the pipe by hot or cold rolling. For spiral welded pipes, the metal strip is usually coiled into a spiral shape.

4.Welding

Weld the spiral shaped tubes together using an appropriate welding process such as TIG welding or MIG welding. The welding parameters need to be controlled during the welding process to ensure the quality and strength of the weld.

5.Cooling Down

After welding, the pipe needs to be cooled to ensure the stability of the weld and the pipe as a whole.

6.Post-processing

Pickling and passivation treatments are performed to remove oxides and impurities generated during welding and to improve corrosion resistance.

7.Testing and Inspection

Perform various tests on welded pipes, including non-destructive testing (such as ultrasonic testing, X-ray testing) and mechanical property testing (such as tensile strength, elongation, etc.) to ensure that the products meet relevant standards and customer requirements.

8.Surface treatment

Surface treatment such as sandblasting, polishing or coating is performed according to customer needs to improve the corrosion resistance and appearance of the pipeline.

9.Packaging and Shipping

Properly pack the qualified Inconel 625 spiral welded pipes to ensure they are not damaged during transportation and then ship them to customers.