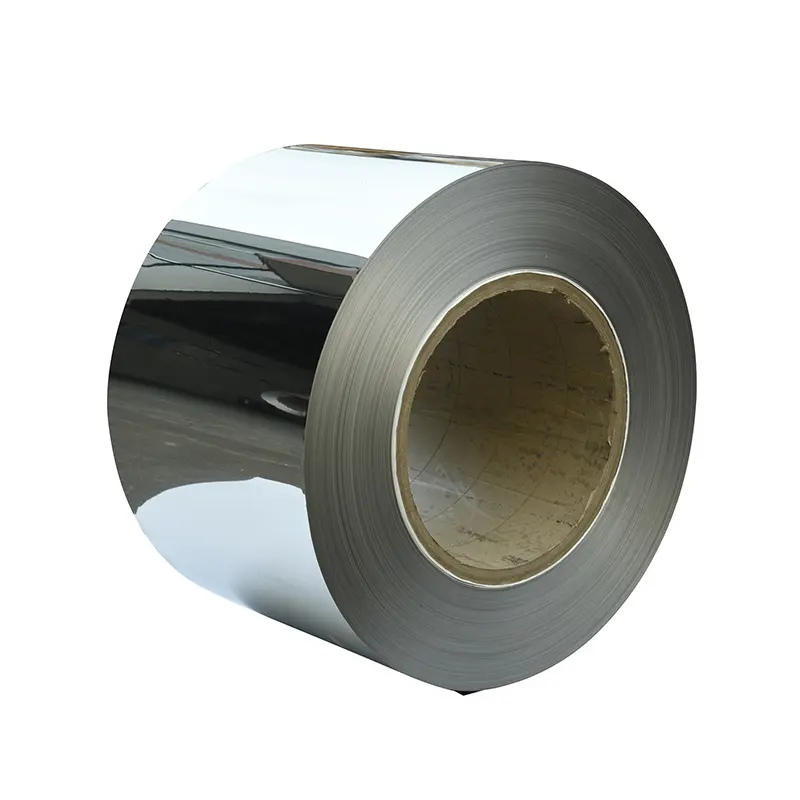

Monel 400 coil suitable for heat exchangers

specification

| Product Name | Monel 400 Coil |

| Standard | ASTM,JIS,DIN,GB,AISI,DIN,EN |

| Thickness | 2.5mm-10.0 mm |

| Width | 610-2000 mm |

| Length | 2000mm, 2438mm, 3000mm, 5800mm, 6000mm, 12000mm, etc. |

| Error | ±1% |

| Certification | ISO 9001 ,CE,API |

| Surface treatment | BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

| Production Technology | Hot Rolling, Cold Rolling |

| Country of origin | China |

| Main Applications | Automobile industry, machinery manufacturing, construction engineering, oil and gas industry, aerospace, power industry, home appliance industry |

| Package | Plastic film packaging, wooden pallet packaging, steel strapping, carton packaging, anti-rust oil coating, container transportation, customized packaging |

| Payment Term | TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

| After-sales service | 1. Quality assurance period 2. Return and exchange policy 3. Delivery and acceptance assistance 4. Customer feedback collection |

Product Display

Chemical Composition

|

Nickel, minA |

Copper |

lron, max |

Manganese, max |

Carbon, max |

Silicon, max |

Sulfur, max |

|

63.0% |

28.0% - 34.0% |

2.5% |

2.0% |

0.3% |

0.5% |

0.024% |

Mechanical Properties

|

Condition (Temper) |

Tensile Strength, min, psi (MPa) |

Yield StrengthA (0.2 % offset), min, psi (MPa) |

Elongation in 2 in. or 50 mm, or 4D, min,% |

Rockwell Hardness (B Scale)b,c |

|

Hot-Rolled Plate |

||||

|

Annealed |

70000 (485) |

28000 (195) |

35 |

- |

|

As-RolledD,E |

75000 (515) |

40000 (275) |

25 |

- |

|

Hot-Rolled Sheet |

||||

|

Annealed |

70000 (485) |

28000 (195) |

35 |

- |

|

Cold-Rolled Sheet |

||||

|

Annealed |

70000 - 85000 (485 - 585) |

28000 (195) |

35 |

- |

|

Quarter-Hard |

- |

- |

- |

73 - 83 |

|

Half-Hard |

- |

- |

- |

82 - 90 |

|

Hard |

100000 (690) |

90000 (620) |

2 |

- |

|

Cold-Rolled Strip |

||||

|

Annealed |

70000 - 85000 (485 - 585)F |

28000 (195) |

35F |

- |

|

Skin Hard |

- |

- |

- |

68 - 73 |

|

Quarter-Hard |

- |

- |

- |

73 - 83 |

|

Half-Hard |

- |

- |

- |

82 - 90 |

|

Three-Quarter-Hard |

- |

- |

- |

89 - 94 |

|

Hard |

100000 (690)F |

90000 (620)F |

2F |

- |

|

Spring Temper |

- |

- |

- |

98 min |

Physical Performance

| Units | Temperature in°C | |

|

Density |

8.14 g/cm³ |

Room |

|

Specific Heat |

0.105 Kcal/kg.C |

Room |

|

Melting Range |

1370-1400°C |

- |

|

Modulus of Elasticity |

196 KN/mm² |

20° |

|

Electrical Resistivity |

113 µΩ.cm |

25° |

|

Coefficient of Expansion |

14.1 µm/m °C |

25 - 100° |

|

Thermal Conductivity |

11.1 w/m-° K |

25° |