Quality 10# seamless pipe, tough & weld - able

specification

|

Product Name |

10# steel seamless steel pipe |

|

Standard |

ASTM,JIS,DIN,GB,AISI,DIN,EN |

|

Material |

10#, AISI 1010, SAE 1010, S10C, CK10, 040A10 |

|

Outer diameter range |

Small diameter seamless steel pipe: outer diameter is usually 6mm to 108mm. Medium diameter seamless steel pipe: outer diameter ranges from 114mm to 325mm. Large diameter seamless steel pipe: The outer diameter is generally greater than 325mm, and can reach 1425mm and below. |

|

Thickness range |

Small diameter seamless steel pipe (outer diameter is usually less than 108mm) The wall thickness is generally around 1mm to 10mm. Medium diameter seamless steel pipe (outer diameter is roughly between 114mm and 325mm) Wall thickness is roughly in the range of 3mm to 20mm. Large diameter seamless steel pipe (outer diameter greater than 325mm) Its wall thickness is thicker, ranging from 5mm to 200mm. |

|

Length range |

Customized length according to customer's special requirements. |

|

Error |

±1% |

|

Certification |

ISO 9001 ,CE,API |

|

Surface treatment |

Pickling and passivation, galvanizing, painting, plastic spraying, shot blasting, rust removal, polishing |

|

Country of origin |

China |

|

Main Applications |

1.Parts processing: 10# steel seamless steel pipe has good plasticity and machinability, and can be easily made into parts of different shapes and specifications through various mechanical processing processes (such as turning, milling, drilling, etc.). |

|

2.Structural support: In some simple mechanical structures, 10# steel seamless steel pipe can be used as a supporting component. |

|

|

3.Drive shaft and other parts: The drive shaft of a car needs to have a certain strength and toughness to ensure that power can be effectively transmitted during the vehicle's driving. |

|

|

4.Frame parts: 10# steel seamless steel pipes are also used for some frame parts of some light vehicles or special vehicles. |

|

|

5.Scaffolding construction: During the construction process, scaffolding is an indispensable temporary support structure. |

|

|

6.Building water supply and drainage pipes: 10# steel seamless steel pipes can also be used for water supply and drainage pipes inside some buildings or outside small buildings. |

|

|

7.Transportation pipelines: The petrochemical industry requires a large number of pipelines to transport various fluid media, such as crude oil, natural gas, various chemical raw materials and products, etc. |

|

|

8.Equipment support structure: In petrochemical production equipment, a large number of support structures are required to fix and support the equipment. |

|

|

Package |

Simple packaging, reinforced packaging, wooden frame, metal frame, pallet, wrapping |

|

Payment Term |

TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

|

After-sales service |

1. Quality assurance period 2. Return and exchange policy 3. Delivery and acceptance assistance 4. Customer feedback collection |

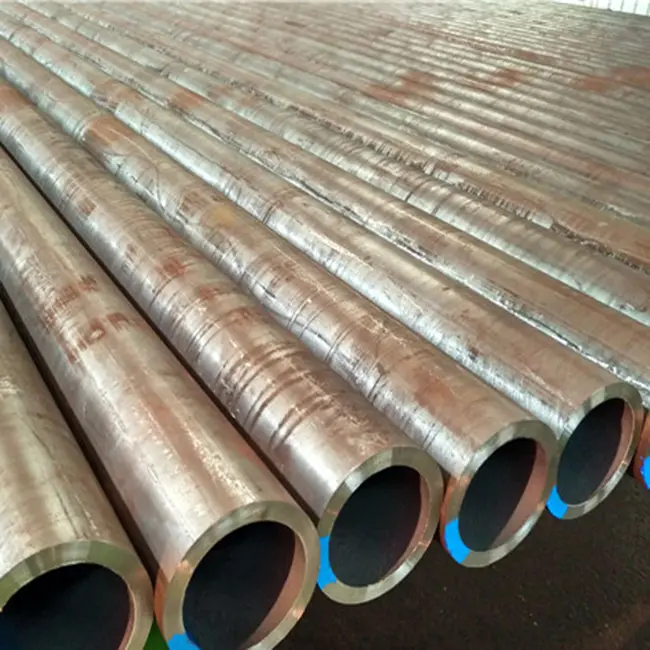

Product Display

Production process

The production process of 10# steel seamless steel pipe mainly includes hot rolling and cold drawing. The following is a detailed introduction:

Hot rolling production process

Pipe blank preparation: Select 10# steel round steel billets that meet the requirements and inspect them, including chemical composition, dimensional accuracy, surface quality, etc., to ensure that the billets are of qualified quality and remove defective billets.

Heating: Send the qualified pipe billets into the heating furnace for heating. The heating temperature is generally around 1000℃-1250℃, so that the pipe billets reach a thermoplastic state, which is convenient for subsequent perforation and rolling.

Piercing: Use a perforator to perforate a hole in the center of the heated pipe billet to form a rough pipe. Common perforation methods include oblique rolling perforation and pressure perforation. During the perforation process, the perforation speed, pressure and temperature parameters should be controlled to ensure the quality of the rough pipe.

Three-roll oblique rolling, continuous rolling or extrusion: The perforated rough pipe is extended by three-roll oblique rolling, continuous rolling or extrusion, so that the outer diameter and wall thickness of the rough pipe are gradually reduced to meet the required size and accuracy requirements. In this process, the roller or extrusion die applies pressure to the rough tube to cause it to plastically deform.

Tube removal: The steel tube after rolling or extrusion is separated from the rolling mill or extruder.

Sizing (or diameter reduction): The steel tube after tube removal is sized or reduced to further improve the dimensional accuracy and surface quality of the steel tube. Sizing is to make the outer diameter of the steel tube reach the specified dimensional tolerance range, while diameter reduction is to appropriately reduce its outer diameter under the premise of ensuring the wall thickness of the steel tube.

Cooling: The steel tube after sizing or diameter reduction needs to be cooled. Generally, air cooling, wind cooling or water cooling are used to reduce the temperature of the steel tube to about room temperature to stabilize its structure and performance.

Straightening: Since the steel tube may bend and deform during the processing, it is necessary to straighten it so that the straightness of the steel tube meets the standard requirements. Straightening methods include pressure straightening, roller straightening, etc.

Hydraulic pressure test (or flaw detection): In order to detect the sealing and internal defects of the steel tube, the steel tube needs to be subjected to hydraulic pressure test or flaw detection. The hydraulic test is to fill the steel pipe with water and apply a certain pressure to observe whether the steel pipe leaks; the flaw detection is to use ultrasonic flaw detection, eddy current flaw detection and other methods to detect whether there are cracks, pores and other defects inside the steel pipe.

Marking: Mark the qualified steel pipes, including the specifications, materials, manufacturers, production date and other information of the steel pipe, for easy identification and traceability.

Warehousing: The marked steel pipes are stored in the warehouse according to specifications, materials, etc., and protective measures are taken to prevent the steel pipes from rusting and damage.

Cold drawing production process

Pipe blank preparation: Similar to the hot rolling production process, first select qualified 10# steel round steel billets, and conduct inspection and peeling treatment to remove surface oxide scales, cracks and other defects to ensure the surface quality of the billets.

Heating: Heat the pipe billet to a certain temperature, generally at Around 800℃-950℃, so that the tube has good plasticity and machinability.

Piercing: Use a piercing machine to pierce holes on the heated tube to form a rough tube.

Heading: The rough tube after perforation is headed, that is, the end is rolled so that its size can pass through the thin end of the cold drawing die.

Annealing: The rough tube after heading needs to be annealed to eliminate internal stress, reduce hardness, improve plasticity, and facilitate subsequent cold drawing. The annealing temperature is generally around 600℃-700℃, and the insulation time depends on the specifications and materials of the rough tube.

Pickling: The rough tube after annealing needs to be pickled to remove impurities such as oxide scale and rust on the surface and improve the surface quality of the steel pipe. Pickling generally uses acidic solutions such as sulfuric acid and hydrochloric acid for soaking or spraying.

Oil coating (copper plating): The surface of the rough tube after pickling is relatively smooth. In order to reduce the friction during cold drawing and prevent scratches on the steel tube surface, it is necessary to apply a layer of lubricating oil or a layer of copper plating on the surface of the rough tube.

Multiple cold drawing: The rough tube after oiling or copper plating is drawn through the cold drawing die for multiple times. The deformation of each drawing should not be too large, generally controlled at about 10%-20%. Through multiple drawing, the outer diameter and wall thickness of the steel tube are gradually reduced to achieve the required size and precision requirements. During the cold drawing process, it is necessary to pay attention to controlling the cold drawing speed, tension and other parameters to prevent defects such as breakage and cracks in the steel tube.

Blank tube heat treatment: The steel tube after cold drawing needs to be heat treated to eliminate the internal stress caused by cold processing and improve the organization and performance of the steel tube. Heat treatment methods are generally normalizing, tempering, etc. The specific heat treatment process depends on the specifications, materials and use requirements of the steel pipe.

Straightening: Similar to the hot rolling production process, the steel pipe after cold drawing also needs to be straightened to ensure that the straightness of the steel pipe meets the standard requirements.

Hydraulic pressure test (flaw detection): Perform hydraulic pressure test or flaw detection on the straightened steel pipe to ensure the quality and safety of the steel pipe.

Cleaning: After the hydraulic pressure test or flaw detection, some impurities such as oil and water stains may remain on the surface of the steel pipe, which needs to be cleaned to ensure the surface cleanliness of the steel pipe.

Marking: Mark relevant information on the cleaned steel pipe, such as specifications, materials, manufacturers, production date, etc.

Warehousing: Classify the marked steel pipes and store them in the warehouse, and take measures such as moisture-proof and rust-proof.

Why choose us, our advantages

1. Procurement of high-quality raw materials: Our company always insists on purchasing high-quality raw materials from reliable suppliers and strictly controls the quality of raw materials. We have established long-term and stable cooperative relationships with many well-known suppliers of raw materials such as iron ore and coke, ensuring that each batch of raw materials used meets or even exceeds industry standards, laying a solid foundation for the production of high-quality steel.

2. Advanced production technology and equipment: We have a set of advanced production processes and modern production equipment, which enables us to accurately control key indicators such as the chemical composition, mechanical properties and dimensional accuracy of steel. For example, we use advanced steelmaking technology, such as converter steelmaking combined with refining technology, to effectively remove impurities and improve the purity of steel; equipped with high-precision rolling equipment to ensure that the thickness of steel is uniform and the shape is regular, meeting the strict requirements of different customers for steel quality.

3. Strict quality inspection system: We have established a complete and strict quality inspection system, and every link is carefully inspected from the entry of raw materials to the delivery of finished products. We have a professional quality inspection laboratory equipped with advanced testing instruments, such as spectrometers, universal testing machines, ultrasonic flaw detectors, etc., which can comprehensively test the chemical composition, tensile strength, yield strength, elongation, weld quality (if any) and other indicators of steel. Only steel products that have undergone strict testing and are all qualified will flow into the market, ensuring that every piece of steel that customers get is a fine product.

4. Multi-material coverage: Our product line is rich and diverse, covering a variety of common steel materials, including carbon steel, alloy steel, stainless steel, etc. Whether it is ordinary carbon steel needed for building structures, high-strength alloy steel used in machinery manufacturing, automotive industry and other fields, or stainless steel with extremely high corrosion resistance requirements, customers can find suitable products in our company to meet the diverse needs of different industries and different application scenarios.

5. Outstanding cost-effectiveness: Although we have made great efforts in cost control, we have never sacrificed product quality in exchange for low prices. On the contrary, we provide customers with cost-effective steel products based on high-quality product quality and reasonable pricing strategies. When customers buy our steel, they can enjoy high-quality product guarantees and relatively affordable prices, which truly achieves value for money.

6. Professional sales team: We have a professional sales team that not only knows the various performance and characteristics of steel products, but also has rich industry experience and good communication skills. We can accurately understand customer needs, provide customers with professional product consultation and purchase suggestions, and help customers quickly and accurately select the most suitable steel products for themselves.

7. Perfect after-sales service: We are well aware of the importance of after-sales service to customer satisfaction, so we have established a perfect after-sales service system. We provide product quality assurance and return and exchange services. During the quality assurance period, if there are quality problems with the product, we will promptly handle the return and exchange procedures for customers; provide technical support and consulting services, and provide timely and accurate answers to various problems encountered by customers in the process of using steel, such as application guidance, processing technology suggestions, etc.; at the same time, we provide good logistics and delivery services, track logistics transportation and assist customers in delivery acceptance; we also actively collect customer feedback and handle it in a timely manner, and continuously improve service quality.